Why Fiberglass Chopper Systems Are Essential for Composite Manufacturing?

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In composite manufacturing, nothing beats the importance of accuracy and productivity in the quality of output. Among those tools which can improve this greatly in the case of the process utilizing fiberglass are the fiberglass chopper systems. These tools are quite important in making composite materials, such as the popular RTM or Resin Transfer Molding process. This enables the companies to simplify their production processes, minimize waste, and ensure that the quality of the fiberglass product is high.

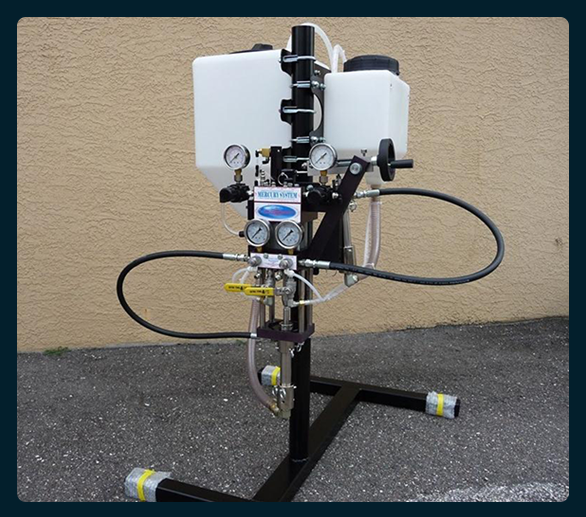

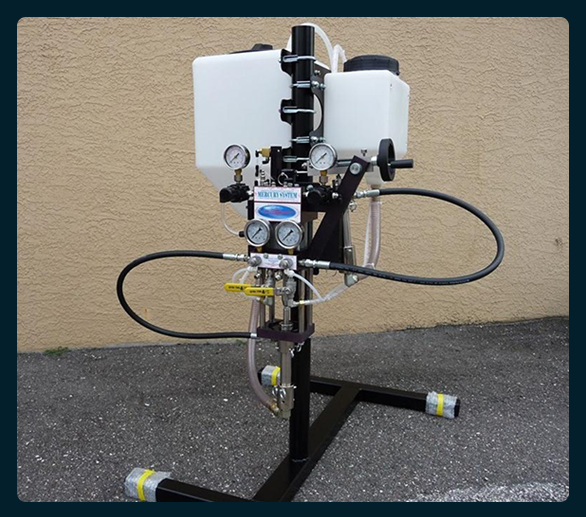

What is a Fiberglass Chopper System?

A fiberglass chopper system is a tool that cuts continuous strands of fiberglass into more manageable lengths. Such a system has been applied in the development of composite materials, primarily involving fiberglass. The chopper system will ensure proper distribution of the fiberglass, thereby giving the final product strength and endurance.

Fiberglass roving is a bundle of long fibers, fed into a cutting mechanism where they get chopped to small lengths suitable for a wide variety of applications. Then, chopped fiberglass is mixed with resin during the RTM/Resin Transfer Molding process, in which it gets injected into a mold to create a solid composite material.

Role of Fiberglass Chopper Systems in Composite Manufacturing

Material Dispensing in Molds

Resin Transfer Molding (RTM) The fundamentals behind the successful composite part rely on equally dispersed fibers and resin. A fiberglass chopper ensures chopped fiberglass fibers distribute adequately in the resin. When chopped fibers are infused, these add strength to the internal structure of the composite while making it lighter and stronger compared to nonreinforced materials.

Chopper systems provide precise and consistent lengths of fibers, which is fundamental in ensuring that the quality and consistency of the final product are well preserved. In other words, the final product will be much stronger and have good performance properties if the fiberglass is better distributed. For this reason, fiberglass chopper systems cannot be avoided in manufacturing processes.

Improved Production Productivity

A chopper system with fiberglass has promoted streamlined production in the process by reducing labor, giving the manufacturer sufficient time with which to prep fiberglass for molding. The old methodology involved cutting fiberglass by hand took a lot of time to do, it was inefficient in providing exactly the same dimensions every other time. With the introduction of the chopper system, a manufacturing company will experience an avenue to increase the speed of manufacture without compromising dimensions saving up on its production time.

This results in significant efficiency for manufacturing industries, especially in the automotive, aerospace, and marine industries where large-scale production is often necessary. The sooner the chopped fiberglass is fed into the RTM/Resin Transfer Molding process, the sooner the manufacturer can begin producing composite parts at a scale with the desired level of quality.

Material Waste Reduction

In composite manufacturing, waste minimization is one of the major concerns. Waste of excess material may result in higher production costs and an environment-unfriendly process. Fiberglass chopper systems help minimize this by cutting material precisely and leaving out as little excess fiberglass as possible. This will mean only the amount of material required for production will be used, thus saving money and making the process more sustainable.

Fiberglass chopper systems also enable manufacturers to design performance parts while keeping the costs of materials under control with optimal material usage. Furthermore, chopped fiberglass in RTM/Resin Transfer Molding helps reduce the probability of air pockets or weak points in the mold and gives a strong and durable nature to the composite part in terms of strength and lifetime.

Manufacturing Flexibility

Another major advantage of a fiberglass chopper system is its versatility. These can be used with a large variety of fiberglass materials, such as different types of roving and even some specialty fibers. Whether it's more traditional fiberglass or advanced composite materials, a chopper system can easily handle whatever demands the different projects present.

This versatility is important for manufacturing companies that produce a variety of products, from car parts to industrial components. With industries constantly demanding more customized and complex fiberglass solutions, fiberglass chopper systems are critical in filling this demand.

Phoenix Equipment - Fiberglass Chopper Systems Leaders

Phoenix Equipment specializes in fiberglass chopper systems for composite manufacturing. Focusing on innovative, dependable solutions that increase production efficiency and material quality, the company delivers solutions that ensure precision and durability in products across automotive, aerospace, and other industries.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.