What Makes Vibration Sensors Indispensable in Today’s Smart Tech?

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

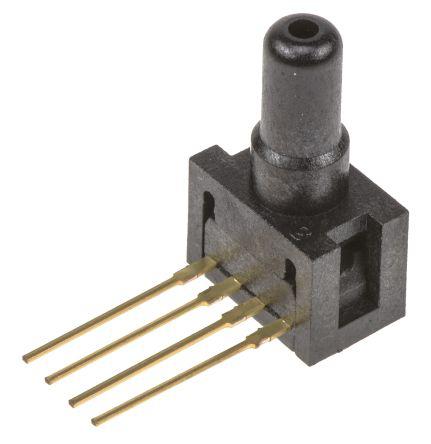

In the realm of intelligent machines and automated electronics, ensuring system stability is no longer a luxury—it’s a necessity. As devices become more sensitive, compact, and interconnected, monitoring even the slightest physical disturbance becomes critical. This is precisely where vibration sensors take the spotlight. Designed to detect oscillations and motion, these sensors serve as the nervous system of countless machines and electronics.

Their role spans across numerous industries and products, enhancing both safety and performance.

Defining the Role of Vibration Sensors

A vibration sensor is a precision device used to measure and respond to mechanical movement. These movements can be natural (such as motor operation) or problematic (such as imbalance or misalignment). Once detected, the sensor converts the mechanical input into a digital or analogue signal, enabling real-time analysis or automated response.

They are widely integrated into microcontroller systems, robotic tools, electronic boards, safety modules, and power management systems.

Industries Relying on Vibration Monitoring

The demand for operational accuracy and predictive analysis has made vibration sensors essential across sectors.

- Manufacturing plants use them to monitor rotating machinery and prevent breakdowns

- Electronics assemblies benefit from internal vibration protection in laptops and microcontrollers

- Transportation systems monitor engine and axle vibration for performance tuning

- Energy systems, including wind turbines and power plants, detect inconsistencies and friction

- Consumer gadgets like gaming controllers and wearables utilise them for interactive feedback

Whether embedded in large contactors or miniature controllers, their presence ensures enhanced control and preventive diagnostics.

Core Principles Behind Vibration Sensing

Understanding how vibration sensors function involves looking into their foundational principles. Each type of sensor is built to respond to specific forms of movement.

- Piezoelectric sensors react to pressure or vibration by generating voltage

- MEMS accelerometers monitor acceleration due to movement or impact

- Strain-based sensors detect material deformation from stress

- Capacitive models sense distance changes caused by oscillation

Each sensor type is uniquely suited to particular environments, whether that’s an industrial motor room or a precision lab filled with microprocessors and capacitors.

Advantages That Go Beyond Detection

What sets vibration sensors apart isn’t just their ability to detect movement—it’s how they add value to the entire system.

- Enable predictive maintenance to reduce machine downtime

- Improve safety by detecting harmful structural stress

- Extend the lifespan of rotating equipment and sensitive electronics

- Support real-time adjustments in automated or AI-driven platforms

- Assist in performance optimisation through accurate feedback

This makes them ideal for a broad spectrum of applications, from tools and fuses to advanced monitoring setups in industrial environments.

The Shift from Reactive to Predictive

Traditional maintenance often relied on periodic inspections or repairs after failure. However, the shift to predictive maintenance relies on vibration sensors to anticipate issues.

These sensors continuously measure vibration levels and patterns, allowing systems to:

- Detect early warning signs of component fatigue or imbalance

- Schedule repairs before significant damage occurs

- Minimise unplanned shutdowns or replacements

- Prevent excess thermal generation from friction

- Enhance machine productivity without manual inspection

Through smart integration, sensors often work in conjunction with controllers and monitoring tools to enable automated decision-making.

Vibration Sensors in Smart Devices

While industrial use is prominent, these sensors are equally valuable in consumer electronics and portable tech.

- Laptops use them to park hard drives during drops or shocks

- Gaming consoles offer immersive feedback via vibration elements

- Wearables track physical activity and motion-based inputs

- Drones use onboard sensors to stabilise flight under vibration

- Smart controllers integrate vibration sensing for motion alerts or control enhancement

These compact sensors enable electronics to respond intelligently to physical changes.

Installation and Integration Considerations

To maximise performance, proper installation and system compatibility are critical. Several factors influence sensor effectiveness:

- Placement close to the vibration source ensures higher accuracy

- Cable quality and connection integrity help reduce signal loss

- Sensor size must suit the design limitations of the device or tool

- Material compatibility with oils, thermal pads, and surrounding components

- Integration with microcontrollers for data analysis and response

- Calibration to match expected frequency and sensitivity levels

A well-matched setup enables seamless functionality and long-term durability.

Evolving Technology in Vibration Sensing

The industry is evolving rapidly, with the development of more intelligent and more efficient vibration sensors. Current innovations include:

- Wireless sensing for flexible deployment and minimal wiring

- AI-driven analytics to interpret complex vibration patterns

- Compact MEMS technology for ultra-light and space-saving use

- Rugged designs to withstand temperature extremes and oils

- Integrated systems with real-time dashboards and cloud support

These trends are making vibration sensing more accessible and impactful across both high-tech industries and consumer-grade applications.

The Broader Impact on Electronics and Automation

Vibration sensors are more than components—they are enablers of intelligent environments. In a connected ecosystem, they work in harmony with:

- Sensors monitoring pressure, temperature, and force

- Controllers that manage logic and automated decisions

- LEDs and displays for user alerts and system updates

- Cables, tools, and switches forming the sensor’s supporting framework

- Safety components like fuses and breakers to prevent damage

By helping each of these elements function predictably and safely, vibration sensors increase both operational intelligence and system resilience.

Wrapping Up

As technology continues to evolve, the demand for stability, performance, and proactive monitoring grows stronger. Vibration sensors meet this need by offering unmatched reliability, integration capabilities, and performance insights. From electronics to heavy machinery, they enable more intelligent systems that act before things go wrong.

No longer confined to niche applications, vibration sensors now define the standard for quality control and predictive technology in everything from innovative tools to high-speed industrial gear. For any engineer or technician aiming to build safer, more intelligent systems—these sensors are not just useful; they’re vital.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.