High-Converting Funnels – From Ad Click to Final Sale!

High-Converting Funnels – From Ad Click to Final Sale!

Why Agricultural Insulation is Key to Efficiency in Thomasville, GA

Written by Premier Insulation GA » Updated on: May 22nd, 2025

Agricultural insulation in Thomasville, GA delivers substantial energy savings and improved operational efficiency by maintaining stable temperatures in farm buildings and equipment. Proper insulation reduces energy consumption by 20-30% annually while creating optimal conditions for livestock, crop storage, and equipment preservation, all crucial factors in Georgia's variable climate.

The right insulation solution addresses Thomasville's specific agricultural challenges, including hot, humid summers and occasional cold snaps. Farms implementing comprehensive insulation strategies report not only energy savings but also improved productivity, extended equipment lifespan, and enhanced animal welfare metrics.

Understanding Agricultural Insulation Types

Agricultural facilities require specialized insulation solutions that differ from residential applications. The appropriate insulation type depends on the specific agricultural operation and facility requirements.

Insulation Type

R-Value Range

Best For

Lifespan

Cost Range

Spray Foam

R-6 to R-7 per inch

Equipment barns, livestock facilities

20+ years

$$$$

Fiberglass Batts

R-3 to R-4 per inch

Storage buildings, hay barns

10-15 years

$$

Reflective Insulation

R-3 to R-6

Poultry houses, dairy facilities

15-20 years

$$$

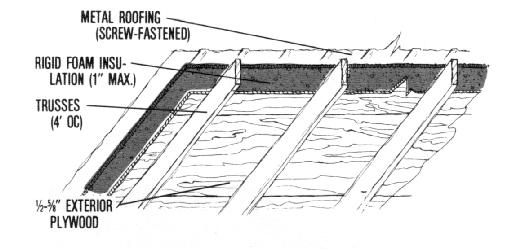

Rigid Board

R-4 to R-6.5 per inch

Cold storage, processing areas

20+ years

$$$

Cellulose

R-3.5 per inch

Attics, wall cavities

15-20 years

$$

Spray Foam Insulation for Agricultural Applications

Spray foam creates an airtight seal that significantly reduces air leakage. In agricultural settings, this translates to better climate control and reduced energy costs.

Bonus Tip: Closed-cell spray foam also adds structural integrity to metal agricultural buildings while providing moisture resistance, particularly valuable in Thomasville's humid climate.

Fiberglass and Cellulose Options

These traditional insulation materials offer cost-effective solutions for certain agricultural applications. They work well in buildings where moisture control is less critical.

Reflective and Rigid Insulation Systems

Reflective systems excel at reducing heat transfer, particularly important for poultry houses and dairy operations in Thomasville's hot climate. Rigid board insulation provides excellent thermal resistance for cold storage facilities and processing areas.

Critical Applications for Farm Insulation in Thomasville

Livestock Housing and Welfare Benefits

Properly insulated livestock facilities maintain consistent temperatures that reduce animal stress and improve productivity. Research shows that temperature-stable environments can improve feed conversion ratios by 5-12%.

Facility Type

Recommended R-Value

Key Benefits

Temperature Range Goal

Dairy Barns

R-19 to R-30

Consistent milk production, reduced heat stress

40-75°F

Poultry Houses

R-21 to R-38

Improved growth rates, lower mortality

65-75°F

Swine Facilities

R-19 to R-25

Better feed conversion, improved breeding

60-75°F

Horse Stables

R-13 to R-19

Joint health, respiratory benefits

45-75°F

Equipment and Storage Protection

Farm equipment represents a significant investment. Insulated storage facilities prevent moisture-related deterioration and temperature extremes that can damage sensitive machinery.

Bonus Tip: Install vapor barriers along with insulation in equipment storage buildings to provide additional protection against moisture damage to metal components.

Crop Storage Optimization

Properly insulated crop storage facilities extend shelf life and maintain product quality. Temperature fluctuations can dramatically reduce crop value and storability.

Crop Type

Optimal Storage Temperature

Insulation Recommendation

Humidity Control Needs

Grains

35-60°F

R-25 to R-30

Moderate

Root Vegetables

32-40°F

R-30 to R-38

High

Cotton

55-75°F

R-19 to R-25

Low

Tobacco

60-65°F

R-21 to R-30

Precise

Peanuts

34-40°F

R-30+

Moderate

Energy Efficiency and Cost Considerations

Agricultural operations in Thomasville face unique energy challenges. According to market data, farms spend an average of $0.15-$0.20 per square foot on energy costs monthly, with heating and cooling representing up to 40% of energy use.

Return on Investment Analysis

While agricultural insulation requires upfront investment, the ROI timeline is compelling:

Insulation Project Type

Initial Cost Range/sq ft

Annual Energy Savings

ROI Timeline

Carbon Reduction

Basic Retrofit

$1.25-$2.75

15-20%

3-5 years

10-15%

Comprehensive System

$2.75-$5.50

25-35%

2-4 years

20-30%

High-Performance System

$5.50-$8.00

35-45%

2-3 years

30-40%

Climate-Specific Considerations for Thomasville

Thomasville's humid subtropical climate creates specific insulation requirements. Summer temperatures regularly exceed 90°F with high humidity, while winter can bring occasional freezes.

Things to Consider Before Making a Decision

Farm-Specific Assessment Needs

Each agricultural operation has unique requirements based on:

- Building construction (metal, wood, concrete)

- Ventilation systems and requirements

- Moisture control challenges

- Long-term usage plans

- Budget constraints

Code Compliance and Regulations

Agricultural buildings must meet specific codes:

- Fire safety ratings for insulation materials

- Vapor barrier requirements

- Ventilation standards for livestock facilities

- Energy efficiency requirements for new construction

Installation Timing and Farm Operations

Consider how installation will impact daily operations:

- Schedule installation during non-peak seasons

- Plan for potential temporary relocation of livestock

- Allow adequate curing time for spray foam applications

- Coordinate with other planned building improvements

Implementation Strategies

Professional vs. DIY Installation

While some insulation projects can be handled in-house, many agricultural applications benefit from professional installation, particularly spray foam and complex systems.

Phased Implementation Approach

For farms with multiple buildings or limited budgets, a phased approach targets the most critical facilities first:

- Livestock housing (direct welfare impact)

- Climate-sensitive crop storage

- Equipment storage and maintenance areas

- Office and processing spaces

Common Questions About Agricultural Insulation

Moisture Control Solutions

Effective insulation systems must address Thomasville's humidity challenges. Proper vapor barriers and ventilation work alongside insulation to prevent condensation issues that can damage structures and stored products.

Ventilation Integration

Balancing insulation with proper ventilation is essential, particularly in livestock facilities where air quality impacts animal health and production.

Bonus Tip: Consider automated ventilation systems that work in harmony with your insulation to maintain optimal temperature and humidity levels while ensuring adequate air exchange.

FAQ

How does agricultural insulation differ from residential insulation?

Agricultural insulation addresses unique challenges like livestock heat generation, high moisture environments, and larger spaces. It often requires higher durability, moisture resistance, and different R-values than residential applications to accommodate farm-specific needs.

What is the best insulation for a dairy barn in Thomasville?

Spray foam insulation typically offers the best performance for dairy barns in Thomasville's climate, providing excellent air sealing, moisture resistance, and consistent temperature control. For budget-conscious options, a combination of rigid board insulation with a proper vapor barrier can also be effective.

How much can insulation reduce my farm's energy costs?

Properly installed agricultural insulation typically reduces energy costs by 20-30% annually for Thomasville farms. High-performance systems may achieve savings of 35-45%, with the greatest impact seen in buildings requiring year-round climate control.

How often should agricultural insulation be inspected or replaced?

Inspect agricultural insulation annually for damage from pests, moisture, or settling. Most quality insulation systems should maintain performance for 15-25 years depending on the material type and environmental conditions, though some damage may require earlier spot repairs.

Can insulation help prevent equipment rust and corrosion in farm buildings?

Yes, proper insulation combined with vapor barriers significantly reduces condensation—a primary cause of rust and corrosion. This protection is particularly valuable in Thomasville's humid climate, extending equipment lifespan and reducing maintenance costs.

Ready to Achieve Greater Farm Efficiency?

Implementing the right agricultural insulation solution addresses Thomasville's specific climate challenges while delivering substantial energy savings and operational improvements. By selecting appropriate materials and focusing on critical applications, farms can experience enhanced productivity and reduced operational costs.

Apply these insights now: Schedule your comprehensive farm insulation assessment with Premier Insulation. Get customized recommendations that align with your specific agricultural needs.

Premier Insulation

(229) 554-3939

Reviewer:

Jack Parker, a spray foam professional with 7 years of experience, reviewed this post and helped improve sections dealing with brand clarity and customer communication.

Jack Parker, a spray foam professional with 7 years of experience, reviewed this post and helped improve sections dealing with brand clarity and customer communication.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.