Why Proper Lighting is Key to Successful Car Wrap and Vinyl Wrap Application?

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Car wrapping, particularly vinyl wrap application, is a highly skilled process that demands precision, attention to detail, and an understanding of the materials used. For automotive professionals and DIY enthusiasts, ensuring that a vehicle wrap is flawless requires the right set of tools—one of the most important of which is proper lighting. The lighting in the workspace can significantly impact the quality of the vinyl wrap application, influencing how well the wrap adheres, how smoothly it lies, and whether imperfections like bubbles, creases, or dust are visible.

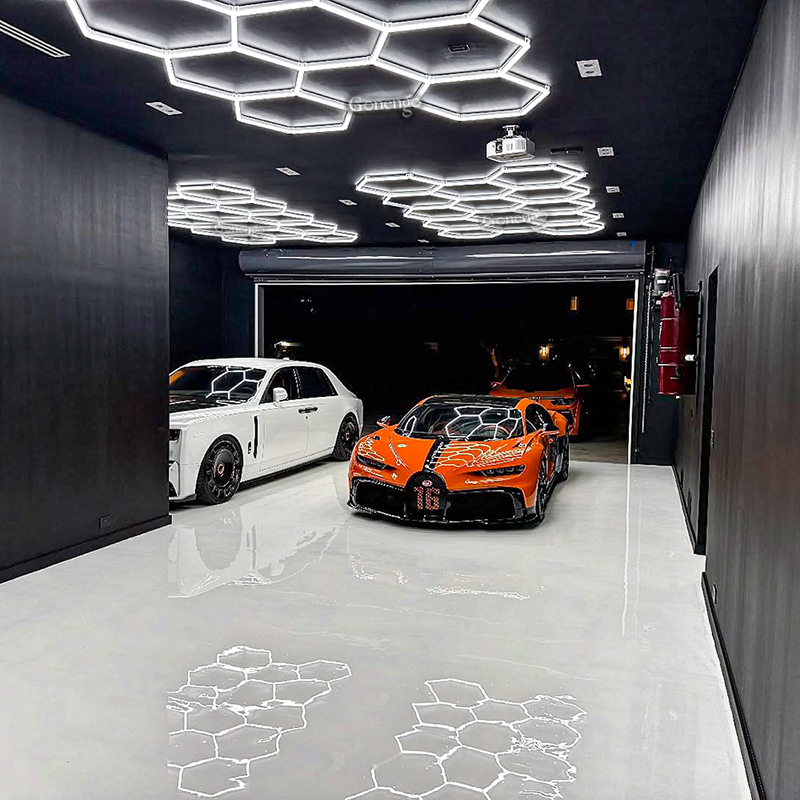

Among the best lighting solutions for this type of work are hex grid LED auto beauty lights. These specialized lighting systems offer several advantages for car wrap professionals, from enhancing visibility to ensuring that every inch of the vehicle is wrapped with precision.

The Importance of Proper Lighting in Vinyl Wrap Application

1. Precision and Visibility

One of the most significant challenges in car wrapping is ensuring the vinyl adheres to the contours of the vehicle perfectly. This requires careful application, especially on curved or irregular surfaces. Poor lighting can lead to missed details, such as bubbles, wrinkles, or areas where the vinyl hasn’t properly conformed to the surface.

High-quality lighting ensures that all areas of the vehicle are evenly illuminated, revealing every imperfection. It helps wrap installers identify areas that need re-adjustment or smoothing out. Without adequate lighting, even the most experienced professionals might struggle to achieve the level of precision required for a flawless wrap.

2. Highlighting Imperfections

When applying vinyl wraps, it’s essential to detect imperfections early in the process. These can include things like small creases, dust particles, or areas where the vinyl might not have adhered properly to the surface. Imperfections, if left unchecked, can compromise the integrity and appearance of the wrap.

Proper lighting highlights these imperfections and makes them visible from all angles, allowing installers to address any issues before the wrap is fully applied. This is particularly important in automotive applications, where small flaws can be very noticeable, especially on high-gloss or metallic finishes.

3. Improved Color Matching

When installing a vinyl wrap, particularly one that is custom-printed or textured, it's important that the colors align perfectly across the entire vehicle. Lighting plays a crucial role in ensuring that the color and texture of the vinyl match as closely as possible to the design specifications, especially when working with colors that are sensitive to light, such as metallics or pearlescent finishes.

Hex grid LED car maintenance lights help maintain color consistency throughout the workspace, allowing professionals to apply vinyl wraps with a greater degree of accuracy. The proper light temperature and distribution minimize color distortion, ensuring that the final result is true to the designer’s vision.

How Hex Grid LED Auto Beauty Lights Improve Vinyl Wrap Application

Now that we've established the importance of proper lighting for a successful vinyl wrap, let’s take a deeper look at how hex grid lights for showroom car workshop detailing lights are an ideal lighting solution for car wrap professionals.

1. Even Light Distribution

Hex grid LED lights for detailing are designed to distribute light evenly across the entire surface of the vehicle. Unlike traditional overhead lights that may create harsh shadows or hotspots, hexagonal grid patterns ensure that light is cast evenly across all areas of the car. This is especially beneficial in a car wrapping context, as it minimizes shadows that could hide imperfections.

The even light distribution ensures that installers can see the entire surface clearly, making it easier to detect any imperfections or misalignments. This is particularly critical when wrapping difficult areas like bumpers, mirrors, and side panels.

2. Shadow Reduction

One of the most significant benefits of using hex grid LED car wrapping lights is their ability to reduce shadows. Shadows can cause significant problems in vinyl wrap installation, as they can obscure areas that need attention. With traditional lighting setups, the angle and intensity of light can create uneven shadow patterns that make it difficult to see fine details.

Hex grid detailing work lights, however, produce a more diffuse, shadow-free light. This allows installers to work with more accuracy, ensuring that every detail is visible from all angles. The reduction of shadows also helps in creating more consistent vinyl application, reducing the chances of errors during installation.

3. Ideal Light Temperature

When it comes to wrapping a vehicle, the temperature of the light is just as important as its intensity. Different light temperatures can alter how colors and materials appear, potentially leading to color mismatch or incorrect application.

Hex grid LED auto repair lights are often designed with a color temperature that mimics natural daylight, providing the best possible environment for vinyl wrap application. These lights have a color rendering index (CRI) that closely matches sunlight, ensuring that colors and textures are accurately represented.

This is especially beneficial for professionals working with vinyl wraps that feature glossy finishes, metallics, or custom designs, as these materials can be tricky to apply without the right lighting. Proper light temperature ensures the vinyl's true colors are visible, allowing the installer to make informed decisions during the wrapping process.

4. Reduced Heat and Energy Efficiency

Traditional halogen or incandescent lights often generate excess heat, which can make working conditions uncomfortable, particularly in a confined space like a garage or workshop. Excess heat can also cause vinyl wraps to become too pliable or soften too much, making them more challenging to work with and increasing the risk of mistakes.

Hex grid LED car care lights produce significantly less heat, creating a more comfortable and controlled working environment. Additionally, these LEDs are much more energy-efficient, which is crucial for long working hours in a professional setting.

5. Customization and Adjustability

One of the key advantages of modern hex grid LED car fix lighting systems is their ability to be adjusted and customized to suit the specific needs of the task. For vinyl wrapping, this means that installers can control the intensity, color temperature, and direction of the light to ensure they have the perfect setup for every job.

This level of flexibility allows professionals to adapt the lighting to suit the vehicle’s shape, size, and the specific details they are working on. Whether they need more focused light for detailed work or a broader, softer light for general application, hex grid LED auto body work lights can be adjusted to meet these needs.

Conclusion

In the world of car wrapping and vinyl wrap application, the quality of the lighting is a make-or-break factor in achieving a professional, flawless finish. Hex grid LED automotive work lights provide the ideal lighting conditions, offering even light distribution, shadow reduction, accurate color temperature, and energy efficiency.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.