Yaskawa Electric Corp: Strategies, Innovations, and Developments in the Denmark Wafer Handling Robots Market

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

The Denmark Wafer Handling Robots Market In the dynamic landscape of semiconductor manufacturing, precision and efficiency are paramount. Yaskawa Electric Corp, a global leader in robotics and automation, has significantly influenced the wafer handling robots market in Denmark. Through strategic initiatives and innovative solutions, Yaskawa has contributed to enhancing Denmark's semiconductor manufacturing capabilities.

Yaskawa Electric Corp: A Global Robotics Leader

Founded in 1915, Yaskawa Electric Corp has a long-standing reputation for excellence in the field of industrial automation. The company's product portfolio includes industrial robots, motion control systems, and robotics systems integration services. Yaskawa's commitment to innovation has positioned it as a key player in various sectors, including semiconductor manufacturing.

Yaskawa's Innovations in Wafer Handling Robotics

Yaskawa Electric Corp has introduced several innovations that have significantly impacted the wafer handling robots market in Denmark:

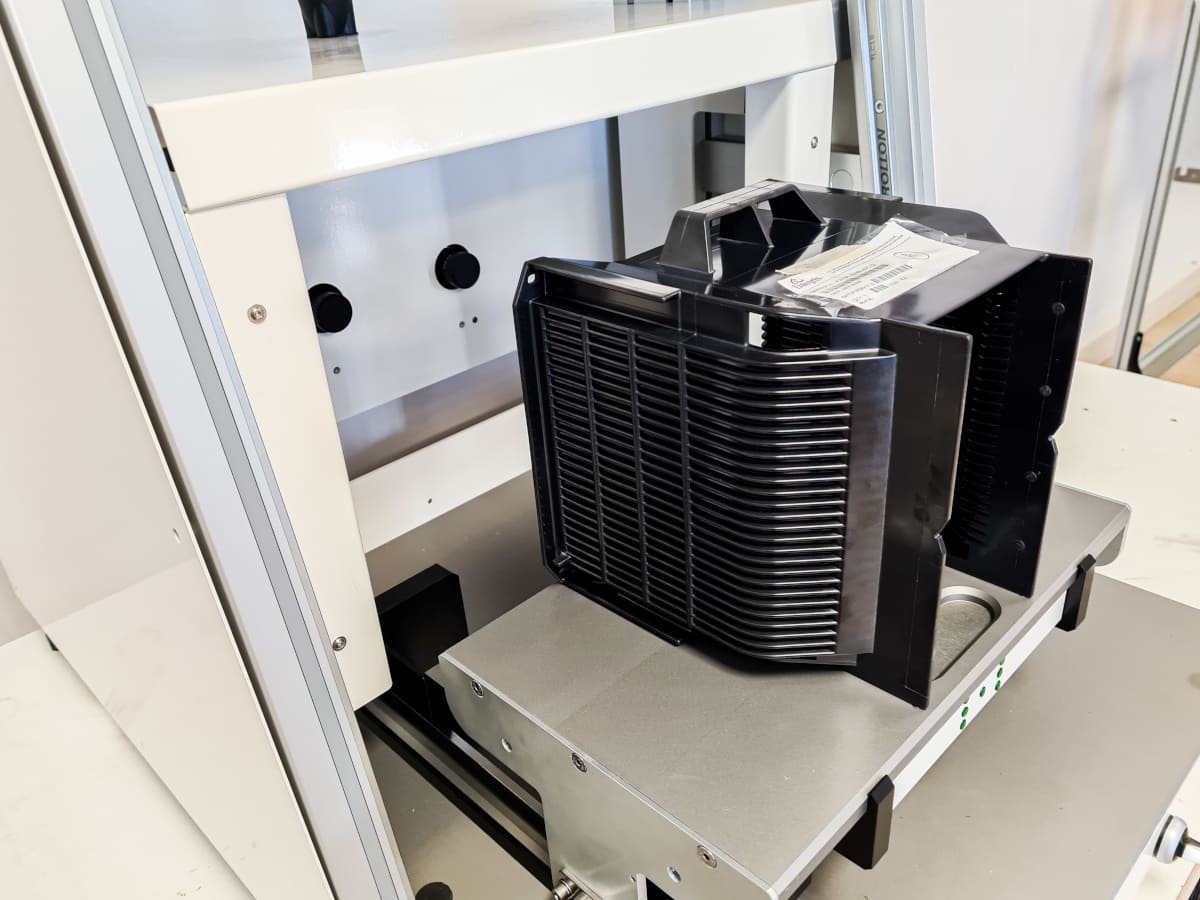

1. Advanced Robotic Solutions: Yaskawa offers a range of wafer handling robots designed for precision and efficiency. These robots are capable of handling various wafer sizes and are equipped with advanced features to ensure minimal contamination and high throughput, meeting the stringent requirements of semiconductor manufacturing.

2. Integration of AI and Machine Learning: By incorporating artificial intelligence and machine learning algorithms, Yaskawa's robots can adapt to dynamic manufacturing environments. This adaptability enhances operational efficiency and reduces the likelihood of errors, contributing to improved yield rates in semiconductor production.

3. Collaborative Robotics: Yaskawa has been a pioneer in developing collaborative robots (cobots) that work alongside human operators. In the context of wafer handling, cobots assist in tasks requiring delicate handling, enhancing productivity while ensuring the safety of human workers.

Strategic Initiatives in Denmark

Yaskawa's strategic initiatives have been pivotal in strengthening its presence in Denmark's wafer handling robots market:

1. Local Partnerships: Yaskawa has established collaborations with Danish semiconductor manufacturers to tailor robotic solutions that meet local production needs. These partnerships facilitate the customization of robots for specific applications, ensuring optimal performance and integration with existing manufacturing systems.

2. Research and Development (R&D) Investments: Recognizing Denmark's emphasis on innovation, Yaskawa has invested in R&D centers within the country. These centers focus on developing next-generation wafer handling technologies, aligning with Denmark's goal to be at the forefront of technological advancement.

3. Training and Support: To ensure the effective deployment of its robotic solutions, Yaskawa provides comprehensive training programs for Danish manufacturers. These programs cover robot operation, maintenance, and integration, empowering local teams to maximize the benefits of automation.

Impact on Denmark's Wafer Handling Robots Market

Yaskawa's contributions have significantly shaped Denmark's wafer handling robots market:

1. Market Growth: The introduction of Yaskawa's advanced robotic solutions has stimulated market growth, attracting both existing and new players to invest in automation technologies. This influx has broadened the market landscape, offering manufacturers a diverse range of options to enhance their production capabilities.

2. Technological Advancement: Yaskawa's focus on integrating AI and machine learning has elevated the technological standards of wafer handling robots in Denmark. Manufacturers now have access to smarter, more efficient robots capable of adapting to complex manufacturing processes.

3. Economic Impact: The adoption of Yaskawa's robotic solutions has led to increased productivity and efficiency in semiconductor manufacturing. This boost has had a positive economic impact, contributing to Denmark's competitiveness in the global semiconductor market.

Challenges and Opportunities

Despite the positive developments, challenges remain in the adoption of wafer handling robots:

1. High Initial Investment: The cost of acquiring and integrating advanced robotic systems can be substantial, posing a barrier for smaller manufacturers. Addressing this challenge requires demonstrating the long-term return on investment and providing flexible financing options.

2. Skilled Workforce: Operating and maintaining advanced robots require specialized skills. Yaskawa's training programs aim to bridge this gap, ensuring that the workforce is equipped to handle sophisticated automation systems.

Future Outlook

Looking ahead, Yaskawa Electric Corp is well-positioned to continue influencing Denmark's wafer handling robots market:

1. Continuous Innovation: Yaskawa's ongoing commitment to R&D will lead to the development of more advanced, efficient, and cost-effective robotic solutions, further enhancing semiconductor manufacturing in Denmark.

2. Expansion of Collaborative Robotics: As industries move towards more flexible manufacturing systems, Yaskawa's expertise in collaborative robotics will play a crucial role in integrating human and machine operations seamlessly.

3. Sustainability Initiatives: Aligning with global sustainability goals, Yaskawa is exploring ways to make its robotic solutions more energy-efficient, supporting Denmark's commitment to environmental responsibility.

Conclusion

Yaskawa Electric Corp's strategic innovations and developments have significantly shaped the wafer handling robots market in Denmark. Through advanced robotic solutions, strategic partnerships, and a focus on technological advancement, Yaskawa has contributed to enhancing Denmark's position in the global semiconductor manufacturing arena. As the industry continues to evolve, Yaskawa's ongoing commitment to innovation and collaboration promises to drive further growth and development

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.