A Complete Guide to Vertical Multistage Pumps

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

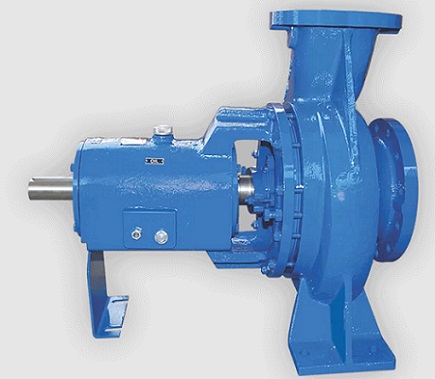

Vertical multistage pumps are a type of centrifugal pump designed to handle liquids in different commercial applications. They are designed to conserve space, energy and have countless functions such as low noise degrees and high-pressure capacities.

Design of Vertical Multistage Pumps

Vertical multistage pumps are designed with multiple impellers attached in series, using either a straight or vertical configuration. The impellers are developed to increase the pressure of the fluid as it moves from one stage to the next. The pump casing confines and shields the pump's interior parts. It likewise includes an inlet and outlet line, fill, and drainpipe ports.

Typical materials for these pumps are cast iron coverings, stainless steel, or a mix of both. The impellers can be made from stainless steel or bronze to deliver extensive service life and minimize wear. These materials are chosen to stand up to the required problems typically encountered in thermic fluid systems, such as high temperatures and corrosive environments.

Stainless steel supplies excellent resistance to rust and thermal anxiety, while bronze impellers offer exceptional wear resistance. This mix of materials makes sure that thermic fluid pump run effectively and with minimal maintenance over extended periods.

How Vertical Multistage Pumps Operate

The operation starts with suction that brings the fluid into the initial impeller, where the impeller increases the liquid from the inlet to release it under high pressure before it flows onto the next stage. The resulting fluid pressure is enhanced at each phase as it flows from discharge to the inlet of the following phase. The last stage, discharge, is commonly linked to a discharge valve for flow control.

These pumps are made to run as a dynamic system. This approach makes sure that pump efficiency is adapted to match modifications in flow problems and changes the motor's power usage. This style feature implies that these pumps are automatic and very effective. The dynamic system design optimizes power usage, lowering operational prices and ecological impact. In addition, the self-regulating nature of these pumps minimizes the risk of overheating and extends the lifespan of the pump elements.

Advantages and Disadvantages of Vertical Multistage Pumps

Benefits:

- Compact Design

Vertical multistage pumps have a space-saving upright orientation, which needs less floor area compared to various other pump types. This makes them perfect for installations where the area goes to a cost.

- Protected Internal Components

The vertical design makes certain that internal components are well-protected from environmental aspects such as dust and debris. This protection contributes to the pump's long service life and reduces the regularity of upkeep.

- Flexible Designs

These pumps offer a high degree of customization. They can be customized to meet certain application requirements, which boosts their adaptability and makes them suitable for a wide variety of industrial and business usage.

- Durability

Constructed to stand up to high pressures and demanding problems, vertical multistage pumps are made from durable materials that are immune to deterioration and wear. This longevity makes certain reliable efficiency over an extended duration.

- High Performance

With numerous impellers installed on a solitary shaft, vertical multistage pumps are capable of producing greater stress while keeping power performance. This makes them suitable for applications needing high-pressure outcomes.

Disadvantages:

- High Initial Cost

The advanced style and top-quality materials utilized in vertical multistage pumps cause a reasonably high preliminary expense. While the performance and toughness of these pumps can warrant the investment, the ahead-of-time expense can be a barrier for some individuals.

- Maintenance Space Requirements

The vertical arrangement of these pumps can produce difficulties when it concerns maintenance. Sufficient vertical clearance needs to be supplied to permit the elimination and maintenance of the pump, which can be tough in cramped setups.

- Installation Complexity

Correct installation of vertical multistage pumps can be more intricate than that of various other pump kinds. Ensuring appropriate positioning and safe installation in an upright setting needs specific preparation and proficient labor.

- Restricted Flow Rate

Although vertical multistage pumps master creating high pressures, their circulation price capacity is generally lower compared to single-stage pumps. This restriction can limit their use in applications that require high flow prices.

- Sound Levels

While typically quieter than many other kinds of centrifugal process pump, vertical multistage pumps can still produce sound, especially in high-pressure applications. This sound can be a factor to consider in setups where peaceful operation is important.

Applications for Vertical Multistage Pumps

Vertical multistage pumps are excellent at pumping tidy, non-abrasive fluids in various commercial applications, such as oil refineries, chemical handling plants, power plants, high-rise buildings, and wastewater therapy plants. By being used in high-rise buildings, vertical centrifugal pump offers high-pressure water to the structure floors, making it possible to run countless fixtures concurrently without influencing their procedures.

Conclusion

In conclusion, vertical multistage pumps are superb for customers who call for high-pressure pumping applications. Their compact design, flexible configuration, and adjustable features make them energy-efficient, and economical and offer long service life. Even though they have some downsides, the benefits surpass the expenses for applications with the required requirements. To pick the optimal centrifugal multi stage pump manufacturer, collaborating with industry leaders is recommended to ensure an appropriate and reliable setup.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.