Complete Selection Guide for Vertical Centrifugal Pumps

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

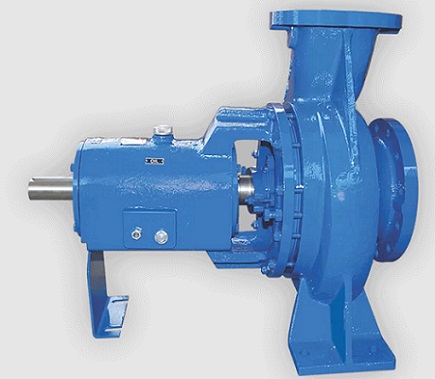

A Vertical centrifugal pumps is a popular type of pump that has an arrangement that is vertical to suit a range of commercial and industrial uses. If you are considering a vertical centrifugal pumps, it is important to take into consideration the head and flow requirements in order to make sure that the performance of the pump is in line with what is required by the specific process.

In many cases, especially where the fluid source is located below ground level or in a sump, a vertical submerged pump may be the preferred configuration.

1. The Resistance to Corrosion and Material of a Vertical Centrifugal Pump

Stainless Steel

Stainless steel is an extremely popular pump product that is extremely resistant to corrosion. There are a variety of grades of stainless steel can handle a variety of acids bases, salts, bases and liquids that are corrosive.

Nickel-Based Alloys

These alloys are known for their superior corrosion resistance and are ideal to handle acidic media as well as extreme temperatures. The most common nickel-based alloys are Monel as well as Hastelloy.

Polypropylene

Polypropylene can be described as a plastic with a high resistance to corrosion that is widely utilized to handle acidic solution gas, corrosive gases, as well as certain organic solvents.

Polytetrafluoroethylene (PTFE)

PTFE is an excellent non-metallic material with excellent corrosion resistance and anti-adhesion properties. It is commonly employed to handle high acidity as well as strong alkali, and also high temperatures medium.

Corrosion-resistant Coatings

There are times when the material that is used to make the pump might not be able to provide adequate corrosion resistance. Therefore, corrosion-resistant coatings may be employed in order to enhance the corrosion resistance to the pumps. The most common coatings are fluoroplastic coatings, as well as rubber coatings.

2. Considering the Efficiency and Consumption of Vertical Centrifugal Pumps

Efficiency

The effectiveness of a vertical centrifugal pumps is determined by the ratio between the power input that is converted by the pump as well as the energy of the fluid output. Pumps that are high-efficiency produce the necessary head and flow with lower energy losses. When choosing a pump focus should be given to its efficiency index and the type of pump that has an efficiency index that is high should be chosen.

Design and Manufacturing

The quality of a pump's design as well as manufacturing has a significant effect on its performance. A well-designed impeller, an optimized flow channel design, lower levels of friction inside and loss and loss of internal friction are all ways to improve the effectiveness that the pump. Furthermore, the choice of premium materials and exact manufacturing techniques can improve the reliability and efficiency of the pump.

Matching of Working Points

Vertical centrifugal pump generally have the optimal operating point in the work curve. This is the place where they are able to operate at their highest effectiveness. For practical use it is essential that the right type of pump and size needs to be picked in accordance with the requirements to ensure that the pump can run at the right work point, which will increase efficiency while reducing energy usage.

Control System

Implementing a more advanced control technology, for example a frequency converters, which can alter the power output and speed of the pump in accordance with current needs. By using the control system, the operational state of the pump is altered in response to changes in flow and the process's requirements which will help reduce the energy use and increase energy efficiency.

Maintenance

Maintenance and routine maintenance will ensure proper operation and performance of centrifugal vertical pumps. Cleaning and inspections regularly of components in the pump, as well as replacement of damaged parts, adjustments of the fasteners and fasteners, etc. will reduce efficiency and loss of friction of the pump and increase the lifespan of the pump.

3. Determine Maintenance and Upkeep Requirements

Examine the Working of Your Pump

Check regularly the status of running the pump. This includes variables like the speed, vibration, temperature and so on. To ensure proper operation of the machine. If you find any anomalies it is recommended to take steps to fix or modify the pump at a later date.

Clean the pump body and the screen

Cleaning the outside and inside of the body of your pump to remove dust and accumulation, particularly the impeller as well as the filter screen that is located at the inlet. This helps prevent the clogging of the pump and reduces the effectiveness for the pump.

Verify seals and bearings

Regularly check seals on the pump and bearings in order to determine wear. If needed you need to replace the worn seals or bearings at the appropriate time to assure that the seals are tight and stable in the pumps.

Adjustment and calibration

Make sure you regularly check and adjust key parts of the pump. This includes the alignment of the impeller's shaft, as well as the connections of the pump's outlet and inlet outlet pipes. This reduces vibrations and the energy consumed.

Liquid and liquid level examination

Make sure you regularly check the pump's lubrication in order to ensure adequate lubricant as well as the normal functioning. In addition you should check the liquid level to make sure that the pump is operating at a normal level and discharge from the pump.

Record and monitoring

Establish maintenance logs, and frequently keep track of operating data for the pump like head, flow and energy consumption. This can help identify any potential issues early and to take preventive steps.

4. Consider Running into a Pump and Return on Investment

Operating Expenses

A Vertical centrifugal pumps comprise energy use as well as maintenance expenses and repair work. Selecting a pump with high efficiency can cut down on energy use, decreasing operating expenses. Furthermore, frequent maintenance and repairs can cut down on repairs and failure costs.

Return on investment

If you are buying a vertical centrifugal pump it is important to assess the return on investment. This includes evaluating the cost of the unit, expected running time, the cost of energy as well as maintenance expenses. When you take a comprehensive look at these aspects you can determine the ROI duration and financial benefits of the pump are calculated.

5. Verifying the Performance of Vertical Centrifugal Pumps

The Flow Test

Use a flow meter, test the flow rate for the vertical centrifugal pumps. The pump should be run under a variety of loads and then record the flow information. Then compare the data to the flow design for ensuring that the flow output of the pump operates in line with the design flow.

Test of Head

Make use of the pressure gauge or sensor to gauge the height of the horizontal centrifugal pumps under various loading conditions. The pump is run under various operating conditions and document the relevant head data. Comparing the data with the design head to determine if the performance of the head pump satisfies the standards.

Power Test

Using the power meter, or ammeter to measure the power input for the centrifugal vertical pump. Keep track of the input power information for the pump at different load conditions, and then compare it to the original value. This will help to assess the amount of energy consumed as well as the effectiveness of the pump.

Vibration and Noise Testing

The purpose of this test is to conduct vibration and noise testing for vertical centrifugal pumps with the instruments of noise and vibration. Through the detection of the level of vibration as well as the level of noise generated by the pump, its operating status and mechanical efficiency of the pump are assessed.

Testing Sealing

Test the sealing capabilities on the centrifugal vertical pumps to make sure that seals and shaft seals as well as other parts work properly and prevent the leakage.

Temperature Rise Test

Examine the impact of thermal energy on the pump by determining the difference in temperature between the outlet and the inlet of the motor. This will help determine the efficiency and loss of heat of the pump as well as test the performance of the pump.

6. Find a Reliable Supplier Buy From

Selecting a trustworthy supplier to purchase vertical centrifugal pump is essential to guarantee high-quality products and after-sales support. Experience expertise, reputation in product design, quality of the product, support and after-sales services, delivery times, as well as the ability to provide references and suggestions are all things to be considered while choosing the right supplier.

In the midst of many centrifugal pumps manufacturers, SMS Pumps & Engineers is one of the top suppliers. It has a great image and good standing as well as a commitment to the production and distribution of vertical centrifugal pumps over long time. They are a seasoned company with a wealth of expert knowledge. They also have the highest level of expertise and capabilities in design of the product as well as quality and production control.

Conclusion

Working conditions are crucial to choosing the right type of the pump. This is based on the characteristics of the medium, temperature, along with other variables, as well as picking a pump constructed of non-corrosive materials.

Examine the returns on investment as well as operating expenses. Also, take a comprehensive look at the performance, price along with the power consumption, as well as other elements of the pump in order to reap the greatest investment returns.

Then, deciding on a dependable source for your purchase is crucial to assure high-quality products as well as after-sales support, SMS Pumps & Engineers is a pump manufacturers in Ahmedabad, India worth considering.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.