Accelerating Soil Consolidation with PVDs: A Smart Engineering Solution for Modern Infrastructure

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Infrastructure development often faces a critical challenge—unconsolidated soft soil. Whether it’s the foundation for highways, airports, or seaports, unstable ground conditions can delay construction, compromise structural integrity, and inflate costs. This is where Prefabricated Vertical Drain / PVD systems come into play. These engineered drainage pathways significantly accelerate soil consolidation, enabling faster and more reliable construction.

NovaGeo Asia, a regional leader in geosynthetic engineering, delivers cutting-edge solutions to optimize ground improvement. Their advanced prefabricated vertical drain products are revolutionizing civil engineering projects across Southeast Asia. With unmatched performance and custom engineering support, NovaGeo’s systems are reducing timelines and costs while enhancing stability in complex soil environments.

Understanding Prefabricated Vertical Drains (PVDs)

Prefabricated Vertical Drain / PVD systems are engineered to facilitate the escape of pore water trapped in saturated, compressible soils. Soft clay soils, in particular, exhibit low permeability, causing natural consolidation to occur over extended periods. PVDs provide a vertical channel for water to escape more quickly, allowing the soil to compress and strengthen over time.

These drains consist of a flexible plastic core wrapped in a geotextile filter fabric. The core provides a path for water to flow, while the outer fabric prevents soil particles from entering and clogging the system. PVDs are installed vertically in a grid pattern, usually with the help of hydraulic mandrels, and work in conjunction with preloading to create pressure that accelerates the drainage process.

How PVDs Accelerate Construction Timelines

In traditional soil consolidation methods, natural drainage of pore water can take years—delaying major infrastructure works. Prefabricated Vertical Drain / PVD systems drastically shorten this period. By reducing the drainage path from several meters (horizontal) to just centimeters (vertical), consolidation that would normally take years can occur in a matter of months.

This accelerated process enables engineers to initiate construction activities on stabilized soil in record time. NovaGeo Asia’s advanced prefabricated vertical drain systems are optimized for rapid water discharge and clog resistance, ensuring consistent performance even in the most saturated clay layers. The result is shorter construction cycles and earlier project delivery without compromising safety.

Technical Design and Customization by NovaGeo Asia

NovaGeo Asia provides full-spectrum engineering solutions that include soil analysis, drain selection, and optimized layouts. Their PVD systems are available in various widths and core profiles to suit different soil compositions and project demands. Depending on the required consolidation speed and soil characteristics, NovaGeo offers solutions ranging from standard flat-core PVDs to high-flow capacity variants.

Their geotextile filter fabrics are engineered to balance permeability and soil retention, ensuring maximum efficiency. All products are rigorously tested for tensile strength, discharge capacity, and long-term performance. With NovaGeo’s technical team on board, contractors receive more than just materials—they gain expert advice and engineering intelligence.

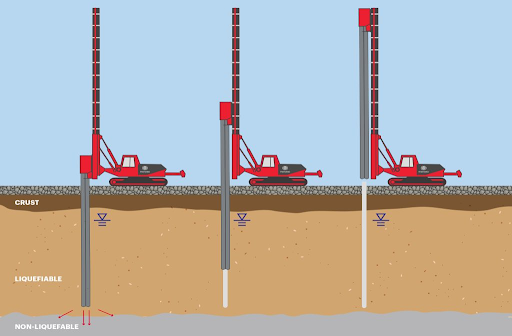

Installation Process of PVDs on Site

The installation of Prefabricated Vertical Drain / PVD systems is precise and efficient. Drains are inserted into the ground using hydraulic mandrels, which are mounted on cranes or excavators. These mandrels push the drain to the desired depth (typically up to 50 meters), then retract, leaving the PVD in place.

The drains are usually installed in a triangular or square grid, depending on the soil profile and desired rate of consolidation. After installation, a preload (such as sand or surcharge) is applied on top of the treated area to exert downward pressure. This pressure expels pore water through the vertical drains, accelerating the consolidation process.

Applications in High-Impact Infrastructure Projects

PVDs are commonly used in large-scale infrastructure projects where ground improvement is essential. Highways, for instance, require stable subgrades to prevent future settlement and cracking. Similarly, airports demand ultra-flat, secure surfaces for runways and taxiways. PVDs make these requirements achievable even on weak soils.

At ports and reclamation sites, soil conditions are often unsuitable for heavy infrastructure due to high moisture content and low shear strength. NovaGeo’s advanced prefabricated vertical drain systems are frequently deployed to prepare these challenging terrains. The drains enable rapid stabilization, allowing heavy equipment and foundation work to begin much sooner.

Real Project Success: Coastal Port Expansion in Malaysia

One of NovaGeo’s flagship PVD projects took place at a coastal port expansion in Malaysia. The reclaimed land consisted mainly of marine clay, which would typically take years to consolidate. NovaGeo engineered and installed over one million linear meters of PVD in a carefully calculated grid pattern.

With the addition of surcharge fill, consolidation occurred within just 6–8 months—cutting project timelines by over 60%. The port authority praised the efficiency, cost savings, and performance stability of the system. This project highlights the transformative impact of advanced vertical drain solutions in the real world.

Environmental and Cost Benefits

Beyond technical performance, Prefabricated Vertical Drain / PVD systems offer noteworthy environmental and economic benefits. Because they reduce the need for extensive excavation or chemical stabilization, PVDs minimize environmental disruption. The use of preloading also limits the need for heavy concrete foundations, cutting down carbon emissions.

From a financial standpoint, faster consolidation means less project overhead. Contractors benefit from shorter rental durations for equipment, reduced labor costs, and minimized risk of delays. NovaGeo’s efficient supply chain and installation planning further reduce total project expenditure.

Seamless Integration with Other Geosynthetic Systems

NovaGeo Asia offers a comprehensive suite of geosynthetic products that work in synergy. For example, Geotextile Bag systems can be used in erosion control near PVD-treated zones. Geomembrane liners are ideal for sealing areas around PVD sites to prevent water infiltration. Geotextile Tube systems support dewatering needs in adjacent construction.

This integration allows project planners to design holistic solutions that enhance efficiency, safety, and sustainability. With NovaGeo’s full-stack geosynthetic offerings, complex infrastructure projects can be executed with greater coordination and reliability.

Benefits for Contractors, Engineers, and Planners

NovaGeo’s advanced prefabricated vertical drain technology provides tangible benefits for stakeholders across the board. For contractors, it translates into easier scheduling, less downtime, and more predictable costs. Engineers appreciate the adaptability and proven performance of PVDs in a wide range of soil conditions.

Urban planners and developers also value how PVDs align with modern development standards. By enabling the use of otherwise unusable land, vertical drains support urban expansion, transportation infrastructure, and industrial growth—all while adhering to sustainability goals.

Future Trends and Evolving Use Cases

As urban expansion accelerates across Asia and beyond, the demand for smarter ground improvement methods continues to rise. Innovations in core design, geotextile materials, and installation technology are further enhancing the performance of Prefabricated Vertical Drain / PVD systems.

NovaGeo Asia remains committed to innovation and excellence. Their ongoing R&D ensures they stay ahead of global trends and continue to deliver value to their clients. Whether it’s a port expansion in Vietnam or a highway upgrade in Indonesia, their advanced prefabricated vertical drain solutions are laying the foundation for tomorrow’s infrastructure.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.