Axial Angular Contact Roller Bearings: A Deep Dive into Their Features and Applications

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Axial angular contact roller bearings are specialized components designed to handle combined axial and radial loads with high efficiency and precision. These bearings are engineered for demanding applications that require robust performance, precision, and reliability, such as heavy machinery, aerospace systems, and industrial equipment. With their unique design and versatile functionality, axial angular contact roller bearings have become an essential solution in industries where conventional bearings might fall short.

This article explores the key features, design configurations, applications, benefits, and maintenance practices of axial angular contact roller bearings, highlighting their role in modern engineering solutions.

What Are Axial Angular Contact Roller Bearings?

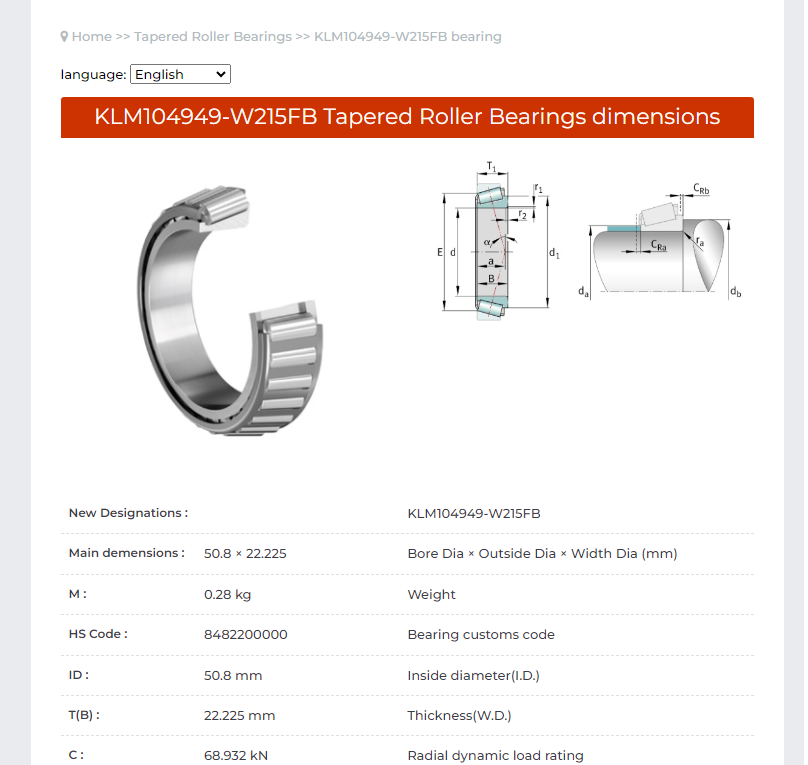

Axial angular contact roller bearings are a type of bearing designed to handle axial loads primarily, with the added capability of accommodating radial loads to a lesser extent. These bearings are characterized by their roller-shaped rolling elements, which provide a larger contact area compared to ball bearings. This design enhances their load-bearing capacity and makes them suitable for applications involving high axial forces and limited space constraints.

The defining feature of axial angular contact roller bearings is the angular contact between the rollers and the raceways. This angle allows the bearing to effectively manage combined loads, offering high stiffness and minimal deformation under stress.

Key Features of Axial Angular Contact Roller Bearings

High Axial Load Capacity

Designed primarily for axial loads, these bearings excel in handling significant axial forces, making them ideal for heavy-duty applications.

Angular Contact Design

The angular alignment of the rollers to the raceways enables the bearing to support combined loads with high precision and efficiency.

Compact and Efficient

Axial angular contact roller bearings offer high performance in a compact design, optimizing space utilization in machinery and systems.

Enhanced Stiffness

The larger contact area provided by the rollers ensures greater stiffness and reduces deflection under heavy loads.

High Durability

Constructed with high-grade materials and precision manufacturing, these bearings are built to withstand challenging operating conditions, including extreme temperatures and heavy loads.

Design Configurations

Axial angular contact roller bearings are available in several configurations to meet diverse application requirements:

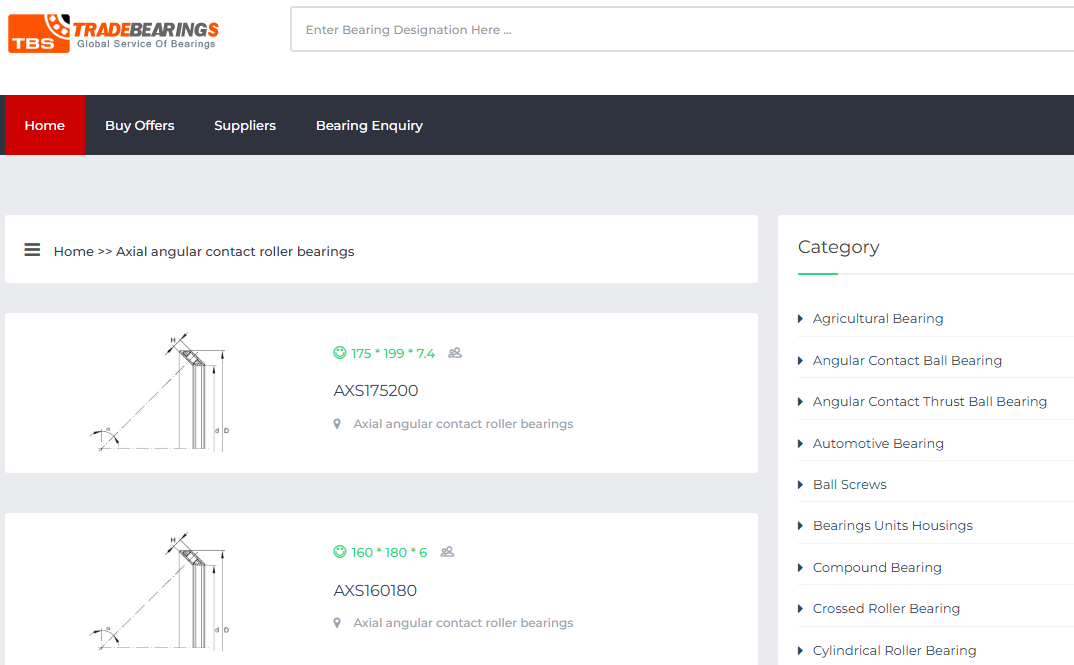

Single-Direction Bearings

Designed to handle axial loads in one direction.

Often used in applications where the load is consistently applied in a single direction.

Double-Direction Bearings

Capable of managing axial loads in both directions.

Ideal for systems with fluctuating or bidirectional axial loads.

Customized Variants

Bearings with specific materials, coatings, or dimensions tailored to meet unique operational needs.

Applications of Axial Angular Contact Roller Bearings

Axial angular contact roller bearings are versatile and find applications in a wide range of industries:

Industrial Gearboxes

These bearings handle the high axial loads generated by gears and shafts in industrial gearboxes, ensuring smooth and efficient operation.

Machine Tools

In precision machining, axial angular contact roller bearings provide the stiffness and load capacity required for accurate and reliable tool positioning.

Aerospace Systems

Used in critical aerospace applications, such as jet engines and landing gear, these bearings ensure dependable performance under extreme conditions.

Turbines and Compressors

The high axial load capacity of these bearings makes them suitable for turbines and compressors, where axial forces are a primary concern.

Construction Equipment

Heavy machinery, such as cranes and excavators, relies on axial angular contact roller bearings to manage the immense loads generated during operation.

Energy Sector

These bearings play a crucial role in wind turbines, where they handle the combined axial and radial forces generated by rotor movements.

Advantages of Axial Angular Contact Roller Bearings

Superior Load-Bearing Capacity

The roller design ensures a larger contact area, enhancing the bearing’s ability to handle high axial loads efficiently.

Precision and Reliability

The angular contact design allows for precise handling of loads, ensuring consistent performance and minimal wear over time.

Space Optimization

The compact design of these bearings allows for efficient use of space, particularly in applications where size constraints are a concern.

Reduced Friction and Wear

Advanced materials and precise manufacturing techniques minimize friction, leading to longer bearing life and reduced maintenance costs.

Customizability

Available in various configurations and materials, these bearings can be customized to meet specific application requirements.

Maintenance of Axial Angular Contact Roller Bearings

Proper maintenance is essential to maximize the lifespan and performance of axial angular contact roller bearings. Here are some tips for effective maintenance:

Regular Inspection

Periodically check the bearings for signs of wear, misalignment, or unusual noise. Early detection of issues can prevent costly failures.

Proper Lubrication

Use high-quality lubricants suitable for the operating conditions to minimize friction and wear. Follow the manufacturer’s guidelines for lubrication intervals and quantities.

Avoid Overloading

Operate the bearings within the specified load limits to prevent premature wear and failure.

Clean Operating Environment

Protect the bearings from contaminants like dirt, moisture, and debris, which can compromise their performance.

Correct Installation

Ensure proper alignment and mounting of the bearings during installation to avoid uneven load distribution and unnecessary stress.

Why Choose Axial Angular Contact Roller Bearings?

Axial angular contact roller bearings are the go-to choice for industries that require reliable, high-capacity bearings for handling axial and combined loads. Their precision, durability, and versatility make them a preferred solution for demanding applications, ranging from aerospace systems to heavy construction machinery.

If you’re in the market for high-quality axial angular contact roller bearings, TradeBearings offers a wide range of options to meet your needs. With their extensive selection and commitment to quality, TradeBearings ensures you get the right bearing for your application. Visit their website today to explore their catalog and elevate your engineering projects with reliable and efficient solutions.

In conclusion, axial angular contact roller bearings are a cornerstone of modern engineering, providing unmatched performance and reliability in even the most challenging environments. Whether you’re building high-speed machinery or designing heavy-duty equipment, these bearings deliver the precision and durability you need to succeed.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.