Tapered Roller Bearings: A Comprehensive Overview

Strong8k brings an ultra-HD IPTV experience to your living room and your pocket.

Tapered roller bearings are vital components in many mechanical systems, renowned for their ability to support heavy loads while providing efficient rotational motion. Their unique design enables them to accommodate both radial and axial forces, making them a popular choice in a variety of industries. This article will explore the features, applications, advantages, selection criteria, and maintenance practices associated with tapered roller bearings, ensuring a comprehensive understanding of their role in engineering.

1. Understanding Tapered Roller Bearings

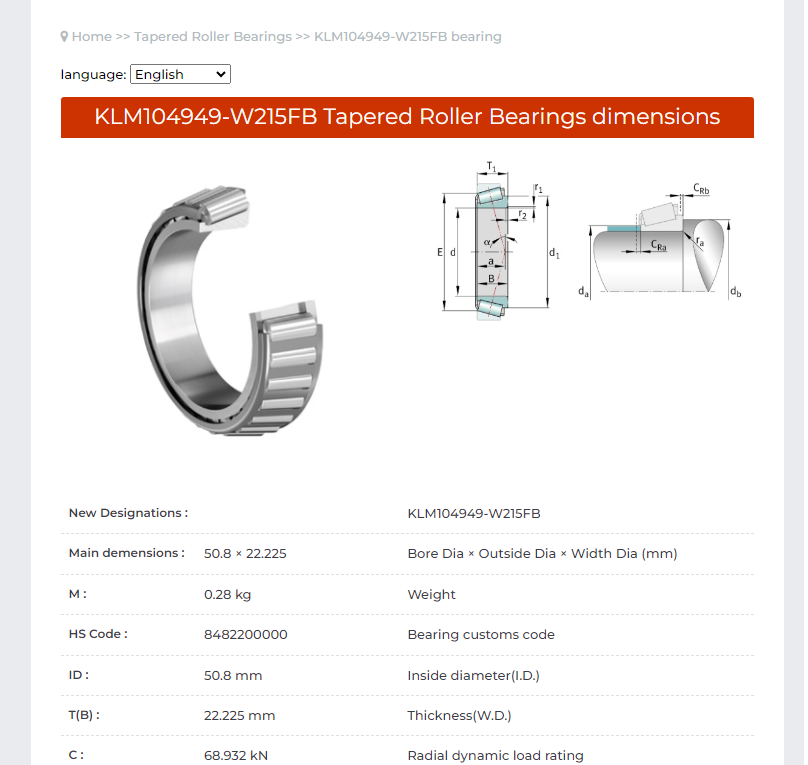

Tapered roller bearings consist of several key components: an inner ring (cone), an outer ring (cup), and tapered rollers arranged between the two. The rollers are shaped like truncated cones, which allows them to make contact with the raceways at a specific angle. This design facilitates the bearing's ability to support radial loads (forces perpendicular to the axis of rotation) and axial loads (forces parallel to the axis) simultaneously.

Key Features:

Tapered Design: The unique shape of the rollers allows for a larger contact area and better load distribution compared to traditional cylindrical bearings. This design results in improved performance under heavy loads.

Versatility: Tapered roller bearings can accommodate a combination of radial and axial loads, making them suitable for diverse applications across multiple industries.

Adjustability: The design allows for adjustment of the clearance between the rollers and raceways, which can enhance performance and prolong bearing life. This feature is particularly useful in applications where thermal expansion and load fluctuations occur.

2. Applications of Tapered Roller Bearings

Tapered roller bearings are widely used in various sectors due to their robustness and versatility. Some of the most common applications include:

a. Automotive Industry

In vehicles, tapered roller bearings are primarily used in wheel hubs, where they support the weight of the vehicle while enabling smooth wheel rotation. They are also found in transmissions and differentials, where they help manage the complex forces involved in power transfer.

b. Industrial Machinery

These bearings are integral to many types of industrial equipment, including conveyors, gearboxes, pumps, and fans. In these applications, tapered roller bearings ensure efficient operation under heavy loads and varying speeds.

c. Aerospace

In the aerospace sector, tapered roller bearings are utilized in critical components such as landing gear and engine systems. Their reliability and ability to handle extreme conditions are paramount in ensuring the safety and performance of aircraft.

d. Construction Equipment

Heavy machinery like excavators, bulldozers, and cranes relies on tapered roller bearings to manage the substantial loads and harsh environments typical of construction sites. These bearings are designed to withstand the rigors of constant use in demanding conditions.

e. Agricultural Machinery

In tractors and other agricultural equipment, tapered roller bearings provide the necessary support for heavy loads and high torque, enabling efficient operation in the field.

3. Advantages of Tapered Roller Bearings

Investing in tapered roller bearings offers numerous benefits, making them a preferred choice for many applications:

a. High Load Capacity

One of the most significant advantages of tapered roller bearings is their ability to handle substantial radial and axial loads. This capacity makes them suitable for heavy-duty applications where other bearing types may fail.

b. Reduced Friction

The tapered design of the rollers minimizes friction between moving parts, leading to improved efficiency and reduced wear. This reduction in friction also translates to lower operating temperatures, which can enhance the overall lifespan of the bearing.

c. Enhanced Durability

Tapered roller bearings are built to withstand harsh conditions, providing a longer service life compared to other bearing types. Their robust construction makes them ideal for applications that involve shock loads and vibration.

d. Improved Performance Under Misalignment

Tapered roller bearings can tolerate slight misalignments, which can occur due to manufacturing tolerances or thermal expansion. This feature contributes to their reliability in real-world applications.

4. Selecting the Right Tapered Roller Bearing

Choosing the correct tapered roller bearing for your application involves several considerations:

a. Load Requirements

Understanding the specific radial and axial loads your application will experience is crucial. This knowledge will help you select a bearing that can handle the expected forces without risk of failure.

b. Speed Ratings

Ensure that the bearing you select is rated for the operational speeds of your machinery. Always consult the manufacturer's specifications for RPM limits to prevent premature wear or damage.

c. Bearing Clearance

Selecting the appropriate bearing clearance is essential, as this can impact performance and longevity. Tight clearances may lead to overheating, while excessive clearances can result in vibration and reduced load capacity.

d. Lubrication Needs

Consider the lubrication requirements of the bearing. Proper lubrication is critical to minimizing friction and wear, and it is essential to use the manufacturer’s recommended lubricants and follow their maintenance guidelines.

5. Maintenance and Care

To maximize the performance and lifespan of tapered roller bearings, follow these essential maintenance practices:

a. Regular Inspections

Conduct routine inspections to check for signs of wear, damage, or contamination. Early detection of issues can prevent costly failures and extend bearing life.

b. Proper Lubrication

Ensure that the bearings are adequately lubricated according to the manufacturer's specifications. Regularly check lubrication levels and replace lubricants as needed to maintain optimal performance.

c. Environmental Protection

Protect tapered roller bearings from dust, moisture, and extreme temperatures that could compromise their performance. Using seals or shields can help mitigate these risks.

d. Correct Installation

Proper installation techniques are critical for the longevity of tapered roller bearings. Ensure that the bearings are aligned correctly and that proper preload is applied, as misalignment or excessive preload can lead to premature failure.

6. Conclusion

Tapered roller bearings like https://en.tradebearings.com/KLM104949_W215FB-1378832.html are indispensable components in a wide array of applications, providing the durability, load capacity, and efficiency needed for demanding environments. By understanding their features, applications, and maintenance needs, you can make informed decisions that enhance the performance and longevity of your machinery.

When sourcing tapered roller bearings, always choose reputable suppliers like TBS-Bearings to ensure high-quality products and reliable support. With the right bearings in place, your machinery will operate more smoothly and efficiently, allowing you to maintain a competitive edge in your industry. Whether you're in automotive, aerospace, or industrial manufacturing, tapered roller bearings are a sound investment for your operational needs.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.