Barrier Films in North America: Market Dynamics, Challenges, and Future Growth Trajectories

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

Barrier films are indispensable in modern packaging. They preserve freshness, enhance shelf life, and protect products from moisture, oxygen, light, and contaminants. In North America, rising consumer demand for sustainable, functional, and high-performance packaging has driven widespread adoption across food, pharmaceuticals, electronics, and industrial applications. The market is experiencing robust technological innovation and rapid expansion.

The Evolution

Barrier films began as simple plastic layers used in food packaging. With evolving consumer expectations and stricter regulatory demands, manufacturers developed multilayered films with enhanced barrier properties. Over time, the inclusion of materials such as EVOH (ethylene vinyl alcohol), aluminum foil, and nanocomposites has significantly improved performance. From single-use layers to recyclable structures, the industry has matured into a complex, innovation-driven ecosystem.

Market Trends – Sustainability and Circular Packaging:

There is increasing demand for recyclable and compostable barrier films. Bio-based materials are gaining traction. – Multilayer Coextrusion Technologies: Advanced film structures allow precise control of oxygen and moisture transmission rates. – Active and Intelligent Packaging: Barrier films are being integrated with indicators, sensors, and antimicrobial agents. – Transparency and Shelf Appeal: Clear high-barrier films are favored for showcasing food products while maintaining protection. – Customized Barrier Performance: Films tailored for specific food items (e.g., oxygen-sensitive produce vs. moisture-sensitive snacks) are increasing. – Shift Toward Retort and Microwaveable Films: Consumer habits are reshaping the requirements for high-heat resistant barrier films.

Challenges – Recyclability and Material Complexity:

Multilayer structures often combine incompatible materials, making recycling difficult. – Regulatory Compliance: Adhering to FDA and Health Canada mandates adds complexity, especially for food and pharma-grade films. – Cost Pressures: High-performance materials and R&D investments elevate production costs. – Competition from Flexible Packaging Alternatives: Paper-based and mono-material flexible options are gaining popularity. – Supply Chain Volatility: Fluctuations in raw material prices and resin shortages impact manufacturing cycles. – Technological Barriers for SMEs: Smaller players struggle to adopt cutting-edge technologies due to capital and expertise constraints.

Market Scope – Application Segments:

Food packaging leads the market share, followed by pharmaceuticals and personal care. The rise of e-commerce has increased usage in protective electronics packaging. – Material Landscape: Key materials include polyethylene (PE), polypropylene (PP), EVOH, polyamide (PA), PET, and aluminum foil. Growth in biodegradable polymers is notable. – Film Types: Co-extruded, laminated, vacuum metallized, and coated films each serve distinct needs. – Packaging Formats: Pouches, lids, wraps, sachets, and blister packs are the leading applications. – Distribution Channels: OEM partnerships, converters, and private label brands constitute primary B2B channels.

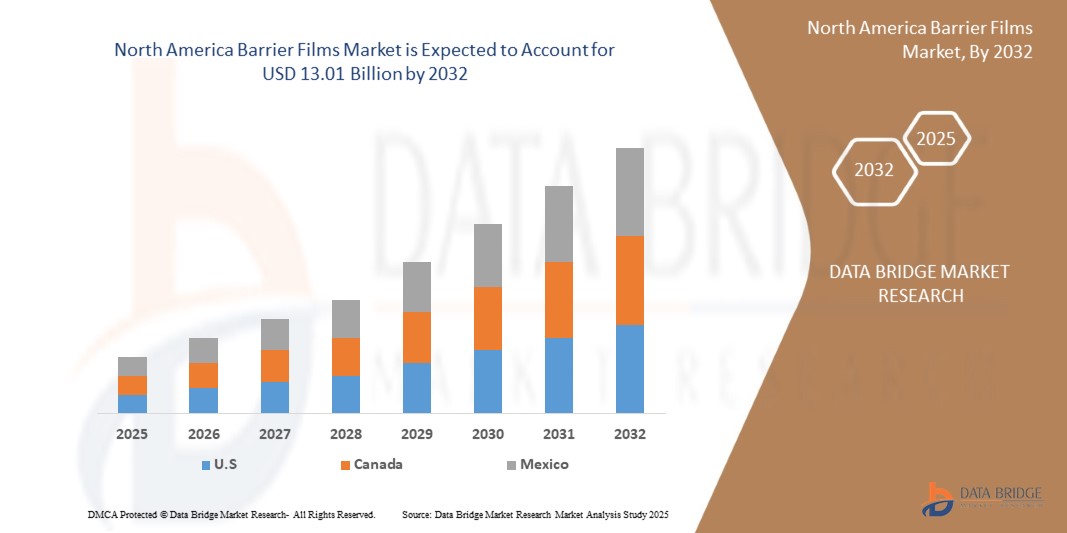

Market Size:

As of 2025, the North American barrier films market is valued at approximately USD 5.3 billion. The sector is projected to grow at a CAGR of 5.6% through 2030, reaching USD 7.0 billion. – United States accounts for over 75% of regional revenue, driven by strong food processing and pharmaceutical industries. – Canada shows promising growth in sustainable packaging investments. – Mexico is emerging as a manufacturing hub with strategic export potential.

Factors Driving Growth – Consumer Preference for Freshness and Convenience:

Demand for ready-to-eat meals and snack packaging drives film innovation. – Rise in Packaged Foods: Urban lifestyles, dual-income households, and health awareness fuel market expansion. – Pharmaceutical Sector Growth: High-barrier blister films and sachets meet stringent drug preservation standards. – Retail and E-Commerce Boom: Protective films for logistics reduce spoilage and damages. – Government and Industry Push for Sustainability: Initiatives promoting recyclable packaging have led to a surge in R&D spending. – Technological Innovation: Nanocoatings, plasma treatments, and bio-based films are transforming the barrier landscape. – Mergers and Acquisitions: Consolidation among converters and material developers expands product reach and capabilities.

Other Trending Reports

https://www.databridgemarketresearch.com/reports/global-mobile-application-market

https://www.databridgemarketresearch.com/reports/global-vitamin-b3-market

https://www.databridgemarketresearch.com/reports/north-america-fall-protection-market

https://www.databridgemarketresearch.com/reports/global-point-of-care-poc-hematology-and-flow-cytometry-market

https://www.databridgemarketresearch.com/reports/global-covid-19-vaccine-packaging-market

https://www.databridgemarketresearch.com/reports/north-america-diabetes-care-devices-market

https://www.databridgemarketresearch.com/reports/asia-pacific-fluorspot-and-elispot-assay-market

https://www.databridgemarketresearch.com/reports/global-cholestatic-jaundice-treatment-market

https://www.databridgemarketresearch.com/reports/global-beverage-coolers-market

https://www.databridgemarketresearch.com/reports/global-bakery-inclusions-market

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.