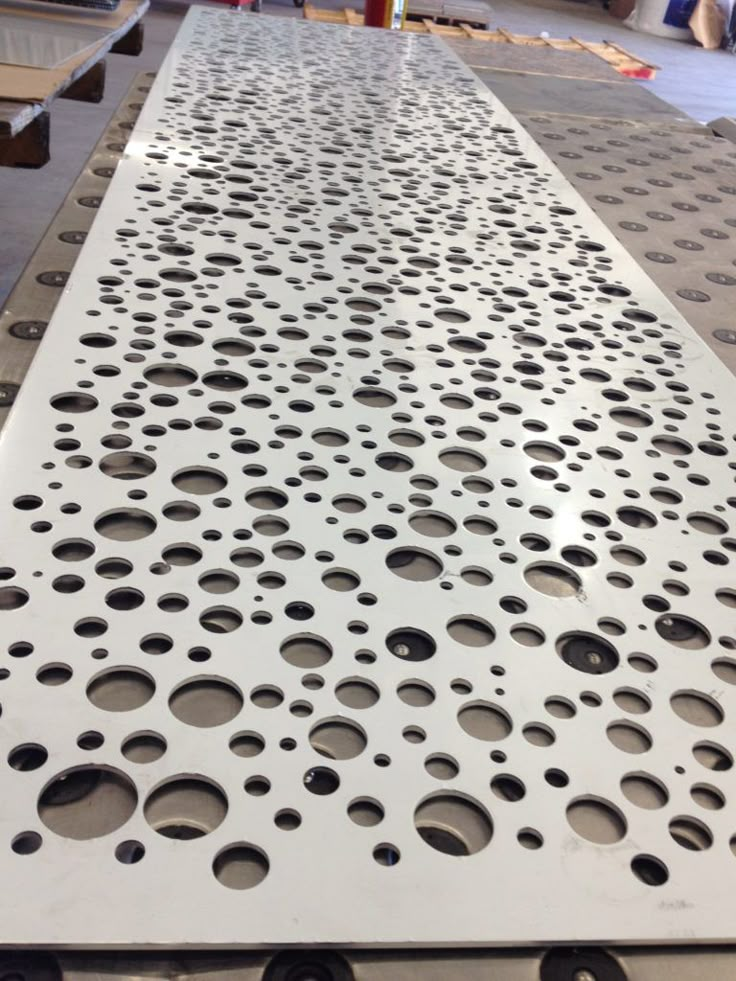

Custom Stainless Perforated Sheets: A Smart Solution for Ventilation and Filtration

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In today’s industrial and architectural landscapes, efficiency, durability, and adaptability are critical. Whether it's optimizing airflow in HVAC systems, maintaining hygiene in food processing plants, or designing high-performance filtration equipment, professionals are turning to a remarkably effective material: custom stainless perforated sheets.

Stainless steel perforated sheets combine the strength and corrosion resistance of stainless steel with the functional benefits of custom-perforated designs. These versatile sheets are proving indispensable in a range of applications, particularly where ventilation and filtration are concerned.

This blog explores why custom stainless perforated sheets have become a smart, go-to solution for ventilation and filtration systems across industries.

What Are Custom Stainless Perforated Sheets?

Perforated sheets are metal panels—typically made from stainless steel—punched or laser-cut with a series of holes, slots, or other patterns. The customization aspect means engineers, architects, or manufacturers can define:

Hole size and shape

Spacing and pattern

Sheet thickness

Surface finish (e.g., brushed, polished, powder-coated)

Stainless steel, thanks to its corrosion resistance, strength, temperature tolerance, and non-reactive properties, is especially ideal for environments requiring sanitation, high durability, and longevity.

When these perforated sheets are designed with ventilation or filtration in mind, the possibilities are not just practical — they’re transformative.

Why Stainless Steel for Ventilation and Filtration?

Stainless steel offers a unique blend of features that make it ideal for both air and fluid systems:

1. Corrosion Resistance

Especially in environments with moisture, chemicals, or high humidity (like industrial kitchens or chemical plants), stainless steel resists rust and degradation over time. This makes it perfect for long-term ventilation or filtration applications without needing frequent replacement.

2. Strength and Rigidity

Unlike plastic or thin aluminum alternatives, stainless steel maintains its shape under stress. This makes it perfect for systems where pressure or weight is a factor.

3. Sanitation and Cleanability

Stainless steel is easy to clean and non-porous, making it ideal for food processing, pharmaceuticals, and any setting requiring stringent hygiene standards.

4. Heat and Chemical Resistance

Custom stainless perforated sheets maintain performance in high-temperature and chemically reactive environments — making them indispensable in industrial exhaust systems and chemical filtration.

Ventilation Applications of Custom Stainless Perforated Sheets

Proper ventilation is essential in a variety of environments — from manufacturing facilities to commercial kitchens, warehouses, and even modern office buildings. Here’s how perforated stainless steel sheets and stamped metal sheets help:

HVAC Grilles and Duct Covers

Stainless perforated sheets are used in air conditioning systems to allow maximum airflow while protecting ducts and systems from debris. Their customizable design enables airflow rates to be adjusted by altering the hole size and pattern.

Ceiling Diffusers and Air Returns

In architectural settings, they serve a dual purpose — blending aesthetically into interiors while ensuring effective ventilation.

Industrial Exhaust Vents

In factories and plants, they are used to manage air exhaust in high-heat or chemical-heavy environments. Stainless steel’s resilience ensures long-term reliability.

Equipment Enclosures

Perforated stainless sheets provide sufficient airflow to prevent overheating of machinery while serving as protective casings.

Filtration Applications of Custom Stainless Perforated Sheets

Whether filtering solids from liquids, separating particles in a gas stream, or removing contaminants, custom stainless steel perforated sheets are used in:

Water and Wastewater Treatment

Used in screens and sieves to remove debris or sediment from water before further treatment stages. Their corrosion resistance ensures durability even in constant exposure to moisture.

Oil and Gas Industry

They’re used in sand control screens and filtration elements in downhole tools, providing strength and precision filtration in harsh environments.

Food and Beverage Processing

Custom perforated sheets are used in straining, sifting, and separating solids in liquids. Stainless steel’s non-reactive surface makes it safe for contact with consumables.

Pharmaceutical and Chemical Filtration

Stainless perforated sheets can be manufactured to exacting specifications, making them ideal for filters where precision and sanitation are essential.

Benefits of Customization

What truly sets these sheets apart is the customizability, allowing engineers and designers to:

Optimize airflow or filtration rate based on exact hole dimensions and distribution.

Control pressure drop in systems by choosing the right open area ratio.

Enhance safety and aesthetics, particularly when the sheets are exposed in public or commercial environments.

Improve system performance, especially in HVAC or processing setups where generic filters fall short.

Using CAD (computer-aided design) and CNC (computer numerical control) technologies, manufacturers can produce intricate and consistent patterns with micron-level precision. This minimizes waste and ensures performance reliability across multiple sheets.

Environmental and Economic Advantages

In an age where sustainability and cost-effectiveness are more important than ever, stainless perforated sheets offer significant benefits:

Reusability and recyclability: Stainless steel is 100% recyclable, making it a green material choice.

Longevity: Reduces need for replacements, saving on material and labor costs.

Low maintenance: Stainless steel requires minimal upkeep, which reduces long-term maintenance expenses.

For industries looking to cut operational costs without sacrificing quality or performance, this solution is both smart and sustainable.

Real-World Examples

Clean Rooms in Electronics Manufacturing

Ventilation panels made from custom perforated stainless steel allow filtered air to circulate freely while maintaining particle control — critical in microchip production.

Food Processing Plants

Drainage panels and steam vents made from perforated stainless steel are used under equipment to facilitate sanitation without interrupting airflow or fluid drainage.

Commercial Buildings

Architects often use stainless perforated panels for ventilated facades or shaded exteriors that allow airflow while protecting against the elements.

Conclusion

Custom stainless perforated sheets are more than just a material choice — they are a strategic solution for industries that value performance, reliability, and customization. Their ability to facilitate optimal airflow and precise filtration, combined with durability and aesthetics, makes them an increasingly popular choice for a wide variety of applications.

Whether you’re designing a next-gen HVAC system, building high-spec filtration units, or looking for sanitary ventilation solutions, stainless steel perforated sheets deliver on all fronts — functionality, longevity, and adaptability.

As industries continue to demand smarter, more efficient systems, these sheets stand out as a smart investment — one that offers long-term value across performance, sustainability, and operational costs.

To read more free articles ( Click Here )

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.