Everything You Need to Know About Cantilever Slitting Machines

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

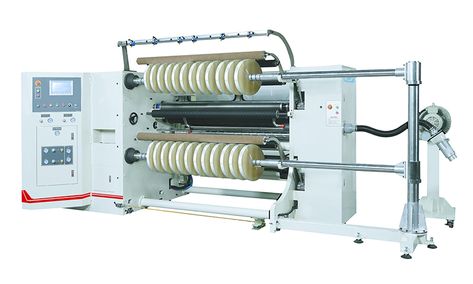

Cantilever slitting machines are an essential part of the industrial machinery landscape, especially in the converting industry. Whether you're involved in paper, plastic film, foil, nonwoven fabrics, or other web materials, a cantilever slitter is crucial for precision slitting and high productivity. These machines are designed to deliver high-speed performance, minimal downtime, and exceptional slitting accuracy, making them the top choice for manufacturers seeking efficiency and quality. This guide explores the key aspects of cantilever slitting machines, from their functionality and components to their industrial applications, benefits, and buying considerations.

What Is a Cantilever Slitting Machine?

A cantilever slitting machine is a type of slitter rewinder used to convert large rolls of material into smaller, manageable widths. The "cantilever" design refers to its open, one-sided structure that allows for easy loading and unloading of parent rolls and rewind shafts. This design reduces downtime and enhances operator efficiency. Cantilever slitters are especially popular in medium to high-speed slitting operations due to their compact footprint and ease of use.

These machines are commonly used in the flexible packaging industry, label production, and the paper and plastic film sectors. With advanced tension control, automatic web guiding, and customizable slitting techniques, cantilever slitters are ideal for both lightweight and heavy-duty materials.

Key Features of Cantilever Slitting Machines

User-Friendly Design

The cantilever structure allows operators to load and unload rolls from one side, making it easy to handle even wide or heavy materials.

High Precision Slitting

Equipped with rotary or razor blade slitting systems, these machines ensure clean and accurate cuts across various substrates.

Adjustable Tension Control

Advanced tension control systems maintain consistent web tension during the slitting and rewinding process, preventing wrinkling or stretching.

Web Guide Systems

Integrated web guiding ensures the material stays aligned throughout the process, reducing waste and improving output quality.

Touchscreen Controls

Most modern cantilever slitting machines come with PLC-based touchscreen interfaces for easy control, monitoring, and job setting.

Compact and Space-Efficient

The cantilever design eliminates the need for dual support shafts, reducing the overall footprint and saving valuable floor space in your facility.

Applications of Cantilever Slitting Machines

Cantilever slitting machines are versatile and can be used across a wide range of industries. Common applications include:

Flexible Packaging Films – BOPP, PET, CPP, LDPE, HDPE, and more.

Label Stock and Adhesive Tapes – Including silicon-coated release papers.

Paper Products – Kraft paper, thermal paper, tissue paper.

Nonwovens and Fabrics – For hygiene, medical, and industrial use.

Aluminum Foil and Laminates – For food packaging and insulation materials.

Types of Slitting Methods

Cantilever slitting machines support various slitting techniques, which can be selected based on the material type and final use:

Razor Blade Slitting – Best for thin plastic films and delicate materials.

Rotary Shear Slitting – Ideal for thick materials or those requiring precise edge quality.

Score Slitting (Crush Cut) – Commonly used for nonwoven and foam products.

Benefits of Using a Cantilever Slitting Machine

Investing in a cantilever slitting machine can deliver several advantages:

Improved Operational Efficiency – Quick roll changeovers and minimal downtime.

Consistent Output Quality – Advanced control systems ensure uniform slitting.

Versatility Across Materials – Suitable for a wide range of substrates.

Reduced Waste – Better alignment and tension management reduce scrap material.

Lower Maintenance Requirements – Fewer moving parts and robust construction.

Choosing the Right Cantilever Slitting Machine

When selecting a cantilever slitting machine, consider the following factors:

Material Type and Thickness – Ensure the machine is compatible with the range of materials you process.

Slitting Width and Rewind Diameter – Choose a model that supports your desired output roll dimensions.

Speed Requirements – Higher production volumes may require high-speed slitting capabilities.

Automation Features – Look for features like auto-tension control, web guiding, and edge sensors.

Support and Service – Choose a manufacturer or supplier who offers good after-sales support and maintenance.

Why Choose Mohindra Mechanical Works?

At Mohindra Mechanical Works, we specialize in manufacturing high-performance cantilever slitting machines tailored to your specific requirements. With decades of experience in industrial machinery and a commitment to quality and innovation, our machines are built to meet the highest standards of durability, accuracy, and efficiency.

Our cantilever slitting machines are:

Engineered with top-grade components for long-term performance.

Customizable to meet industry-specific needs.

Backed by expert technical support and on-site installation services.

Competitively priced with excellent ROI.

Whether you're looking to upgrade your current machinery or starting a new production line, Mohindra Mechanical Works has the right solution for you.

Maintenance Tips for Cantilever Slitting Machines

Proper maintenance is key to ensuring the longevity and reliability of your slitting machine:

Regular Cleaning – Keep the machine free from dust and material residues.

Blade Inspection – Check blades frequently for sharpness and replace them when needed.

Tension System Checks – Ensure that tension controls are calibrated and functioning correctly.

Lubrication – Periodically lubricate moving parts as per manufacturer guidelines.

Software Updates – Keep control software and PLC systems updated to benefit from new features and security improvements.

Conclusion

Cantilever slitting machines are indispensable tools for businesses involved in material conversion and processing. Their design not only simplifies operations but also ensures precision and speed in slitting tasks. Whether you're processing paper, plastic, foil, or fabric, the right cantilever slitter can enhance your production capacity and product quality. For premium machines backed by solid engineering and dependable service, trust Mohindra Mechanical Works—India’s trusted name in slitting and printing machinery.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.