Explore the Best Cantilever Slitting Machines for Sale – Get Yours Today!

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

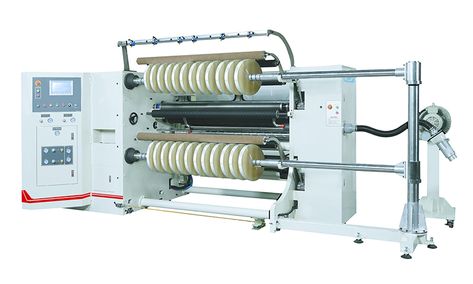

In today’s fast-paced industrial world, efficiency, precision, and durability define the value of any machinery. One of the most crucial equipment for businesses involved in paper, film, foil, and flexible packaging materials is the Cantilever Slitting Machine for sale. At Mohindra Mechanical Works, we understand the importance of providing high-quality, reliable, and performance-driven slitting machines tailored to your business needs.

If you’re looking for the best Cantilever Slitting Machines for sale, this guide will explain everything you need to know—from how they work to what to consider before making a purchase. Whether you're an established manufacturer or a startup in the converting industry, investing in the right machine is the key to long-term productivity and profitability.

What is a Cantilever Slitting Machine?

A Cantilever Slitting Machine is designed to convert large rolls of materials into narrower rolls through precise slitting techniques. Unlike other types of slitting machines, cantilever models feature an open-sided construction, allowing for easy roll loading and unloading from one side. This user-friendly design not only reduces labor time but also ensures faster operation and lower downtime.

These machines are ideal for slitting a variety of flexible materials, including paper, plastic film, aluminum foil, and laminates. Their modular build, coupled with advanced automation options, makes them highly adaptable to different production scales.

Key Features of Cantilever Slitting Machines

When browsing through cantilever slitting machines for sale, it's essential to understand the features that make a machine stand out. Here are some of the most important characteristics:

Open Cantilever Design: Facilitates easy roll handling and maintenance.

High-Speed Performance: Modern cantilever slitters can run at speeds up to 300 meters per minute or more, depending on the material.

Advanced Tension Control Systems: Ensures uniform tension throughout the slitting process, minimizing material distortion and defects.

Customizable Blade Configurations: Rotary, razor, or shear slitting systems can be used based on the material type.

Touch Screen Controls and Automation: Intuitive control panels improve productivity and reduce human error.

Compact Footprint: Designed to save space without compromising on performance.

Why Choose a Cantilever Slitting Machine?

Choosing a cantilever slitting machine means investing in versatility, reliability, and long-term value. Here’s why this machine is a must-have for many industries:

Reduced Downtime: Thanks to its ergonomic design, operators can quickly change rolls and blades.

Enhanced Output Quality: With precision cutting and accurate tension control, you get clean, burr-free edges.

Lower Maintenance: The simple construction and high-quality components require minimal maintenance over time.

Adaptability: Suitable for a wide range of materials and applications, making it a flexible choice for businesses handling multiple substrates.

Applications of Cantilever Slitting Machines

Industries that rely on consistent and accurate material cutting processes find cantilever slitting machines indispensable. Some key sectors include:

Packaging Industry: For slitting laminates, BOPP, PET, and PE films used in flexible packaging.

Printing Industry: For converting large rolls of printed materials into finished sizes.

Label Manufacturing: For precision slitting of label stock rolls.

Adhesive Tapes: For cutting double-sided tapes, masking tapes, and other adhesive materials.

Textile and Nonwoven Fabrics: For cutting synthetic fibers and other fabrics into specified widths.

What to Look for When Buying a Cantilever Slitting Machine

When investing in a cantilever slitter, consider the following factors to ensure you get the best value for your money:

Material Compatibility: Ensure the machine is capable of handling the thickness, weight, and type of material you work with.

Slitting Width and Diameter: Check the minimum and maximum slitting widths and the core diameter range.

Speed and Accuracy: Higher speed is beneficial for large production volumes but must be balanced with precise cutting mechanisms.

Automation Features: Look for PLC controls, automatic web alignment, and tension adjustment features.

Build Quality and Brand Reputation: Opt for a machine from a trusted manufacturer like Mohindra Mechanical Works known for delivering reliable and high-performance equipment.

Why Buy From Mohindra Mechanical Works?

At Mohindra Mechanical Works, we have over three decades of experience in designing, manufacturing, and delivering top-grade slitting and converting machines across India and beyond. Here’s what sets us apart:

Made in India Excellence: Proudly manufacturing machines in India with global standards.

Custom Engineering Solutions: Every machine can be tailored to your specific needs and production requirements.

Affordable Pricing: We offer competitive pricing without compromising on quality or performance.

After-Sales Support: Our expert technical team provides complete support, from installation to maintenance.

Customer-Centric Approach: We believe in building long-term relationships and delivering value beyond the sale.

Frequently Asked Questions

1. What is the delivery time for a Cantilever Slitting Machine?

Most standard models are ready for delivery within 4 to 6 weeks. Custom machines may take slightly longer based on requirements.

2. Do you provide installation and training?

Yes, we offer complete installation support and operator training to ensure smooth setup and operation.

3. Can I request a demo before buying?

Absolutely. We can arrange live or virtual demonstrations so you can see the machine in action before making a decision.

4. What materials can I slit using your machines?

Our machines can handle a wide variety of materials such as paper, films, foils, nonwovens, textiles, laminates, and label stock.

5. Are spare parts and maintenance support available?

Yes, we provide genuine spare parts and long-term maintenance support to ensure minimal downtime.

Get Your Cantilever Slitting Machine Today

Whether you’re upgrading your existing setup or setting up a new production line, investing in the right Cantilever Slitting Machine is a smart move. At Mohindra Mechanical Works, we’re here to help you select a machine that perfectly matches your needs.

Explore our range of Cantilever Slitting Machines for sale, get expert consultation, and take your business operations to the next level. With robust construction, innovative features, and dependable service, our machines are built to perform and last.

Contact us today to request a quote, schedule a demo, or learn more about how we can support your manufacturing journey.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.