Gravure Coating Machine Solutions – Enhance Your Printing & Coating Efficiency

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In today’s competitive world of flexible packaging and industrial converting, the demand for high-quality coating solutions is rapidly growing. Whether you're manufacturing laminates, pharmaceutical films, paperboard, or flexible pouches, one thing remains constant: precision coating plays a vital role in the performance, appearance, and functionality of the final product.

Among the many technologies available, gravure coating machines have emerged as the preferred choice for businesses looking to enhance both printing and coating efficiency. Known for their accuracy, consistency, and adaptability, gravure coating systems are widely used across a range of industries and applications.

In this in-depth article, we’ll explore how gravure coating machines work, the types of coatings they support, the benefits of using this technology, and why Mohindra Mechanical Works is a trusted name for gravure coating machine solutions in India and worldwide.

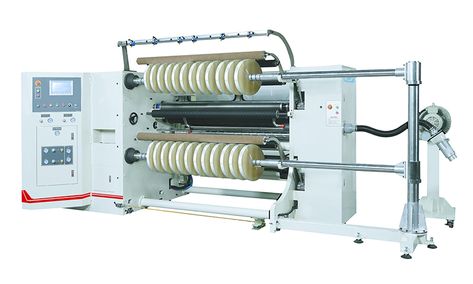

What Is a Gravure Coating Machine?

A gravure coating machine uses a rotating engraved cylinder to apply a uniform layer of coating onto a substrate such as plastic film, foil, paper, or fabric. The coating can range from adhesives and varnishes to functional coatings like barrier films, heat-seal lacquers, or primers.

The machine is a key component in flexible packaging, label manufacturing, medical packaging, and industrial lamination, where high-quality, uniform coating is critical for performance and appearance.

How Gravure Coating Machines Work

The gravure coating process involves a few essential components and steps:

1. Engraved Cylinder (Gravure Roll)

The cylinder has micro-sized engraved cells that hold the coating material. The depth and pattern of these cells determine the amount and distribution of coating.

2. Doctor Blade

This blade scrapes off excess coating material from the surface of the gravure roll, leaving it only in the engraved cells.

3. Substrate Contact

The substrate is pressed against the gravure roll using a rubber-covered impression roller. The coating is transferred from the cells to the substrate in a smooth, controlled manner.

4. Drying System

After coating, the substrate passes through a hot air or IR dryer that evaporates any solvents or water in the coating material, ensuring fast curing and adhesion.

Types of Coating Supported

Gravure coating machines can handle a wide range of coating types, making them extremely versatile. Common coatings include:

Solvent-based coatings

Water-based coatings

UV curable coatings

Adhesive coatings (hotmelt, acrylic, or polyurethane)

Heat-seal coatings

Barrier coatings (oxygen, moisture, grease)

Silicone release coatings

Anti-fog, anti-scratch, and anti-static coatings

Industries That Use Gravure Coating Machines

Gravure coating machines are used in numerous industries where precision coating is essential:

Flexible packaging (lamination films, pouches)

Pharmaceutical packaging (blister foils, medical films)

Label stock and stickers

Tapes and adhesive labels

Paperboard and folding cartons

Photovoltaic and electronic films

Decorative foils and wallpapers

Benefits of Gravure Coating Technology

1. Exceptional Coating Uniformity

Gravure coating is known for tight control over coating thickness, even at very thin microns. This is critical in applications like pharmaceutical packaging, where even the slightest variation can compromise quality.

2. High-Speed Production

Gravure machines can run at speeds of up to 300 meters per minute or more, making them ideal for mass production and high-volume coating requirements.

3. Versatility in Substrates

You can coat a variety of substrates including polyester (PET), BOPP, CPP, aluminum foil, kraft paper, and non-woven fabrics, making it suitable for diverse packaging solutions.

4. Precision and Repeatability

Since the gravure cylinder is engraved with fixed cell patterns, the machine delivers consistent results across long runs, with minimal variation between batches.

5. Scalability and Integration

Gravure coating machines can be integrated with lamination lines, printing machines, slitter rewinders, and inline inspection systems, offering turnkey solutions for end-to-end packaging production.

Mohindra Mechanical Works – Trusted Manufacturer of Gravure Coating Machines

Based in Delhi, Mohindra Mechanical Works is a pioneer in the design and manufacturing of high-performance coating and converting machinery. With more than 30 years of expertise and thousands of machines installed across India and abroad, Mohindra offers custom-built gravure coating solutions tailored to industry needs.

Features of Mohindra Gravure Coating Machines:

Heavy-duty frame construction for vibration-free operation

Precision-engraved gravure rolls with customizable cell depths

Closed chamber doctor blade systems for clean coating

Advanced tension control systems (servo motor driven)

Efficient drying tunnels with hot air and optional IR lamps

PLC-based automation with touchscreen HMI

Energy-efficient and solvent recovery options

Applications of Mohindra Gravure Coating Systems

Mohindra’s gravure coating machines are trusted for a wide range of coating jobs, such as:

Dry lamination and wet lamination adhesive coatings

Primer coating for digital printing substrates

Release liner and silicone-coated paper production

Heat seal coatings on BOPP and PET films

Barrier layer coatings for food-grade packaging

Protective top-coats for scratch resistance

These machines are suitable for both standard production and customized high-performance packaging solutions.

Global Reach and Support

Mohindra has successfully installed coating and laminating machines in more than 35 countries, including:

UAE

Kenya

Bangladesh

Nigeria

Vietnam

Egypt

Sri Lanka

Nepal

South Africa

With a reputation for robust build quality, competitive pricing, and reliable support, Mohindra Mechanical Works is a preferred partner for companies looking to scale their packaging or converting operations.

After-Sales & Technical Support

Purchasing a gravure coating machine from Mohindra is just the beginning. Their comprehensive support includes:

On-site installation and commissioning

Operator training programs

Remote diagnostics and troubleshooting

Spare parts inventory and AMCs

Performance tuning and productivity upgrades

Why Gravure Coating Machines Are the Future

As brands continue to demand smarter, safer, and more sustainable packaging, gravure coating offers a flexible platform for integrating barrier layers, recyclability features, and performance enhancements into packaging structures.

From high-gloss aesthetics to food-grade protection, gravure coating machines deliver precision, efficiency, and innovation, helping manufacturers stay ahead of market demands.

Conclusion

If your business involves coating, laminating, or printing flexible substrates, a gravure coating machine is a strategic investment. It offers unmatched accuracy, production speed, and versatility—making it ideal for manufacturers who aim to deliver high-quality coated products consistently.

At Mohindra Mechanical Works, you’ll find industry-proven machines backed by expert support and custom engineering. Whether you're upgrading your coating line or setting up a new facility, Mohindra ensures that your operations remain efficient, scalable, and future-ready.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.