How Sheet Metal Design Services Can Enhance Product Durability and Performance

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

When it comes to product development, ensuring both durability and performance is crucial to meeting industry standards and customer expectations. In industries such as automotive, aerospace, electronics, and manufacturing, sheet metal plays a key role in creating reliable and high-performing products. This is where expert Sheet Metal Design Services come into play. These services not only contribute to the aesthetics and functionality of a product but also have a significant impact on its overall durability and performance.

1. Precision Engineering for Strength

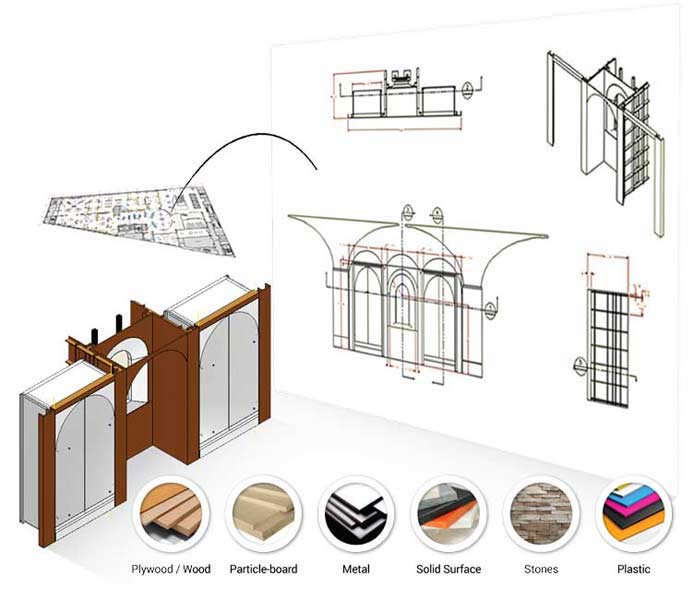

One of the fundamental ways sheet metal design services enhance product durability is through precision engineering. The process involves careful calculation and attention to material properties, ensuring that every cut, bend, and weld is done accurately. When sheet metal is precisely designed, the final product is more resistant to wear and tear, making it last longer under stress and use.

For example, in the automotive industry, precise sheet metal components like body panels and structural supports are designed to withstand the forces they encounter while driving. Through expert design, these parts are optimized to ensure maximum strength without adding unnecessary weight. This balance of strength and weight is critical in enhancing the durability and performance of the vehicle.

2. Optimizing Material Usage

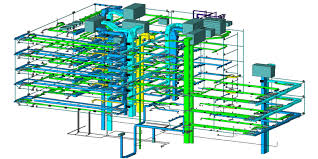

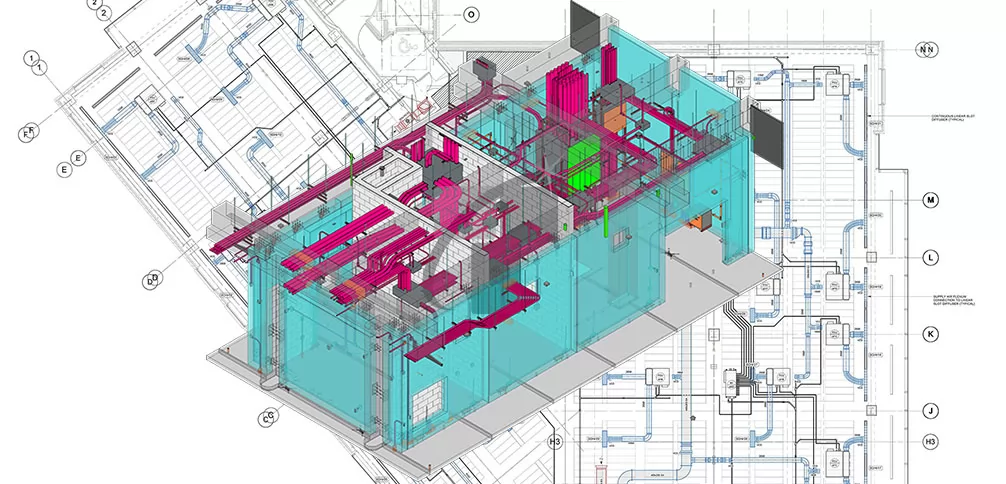

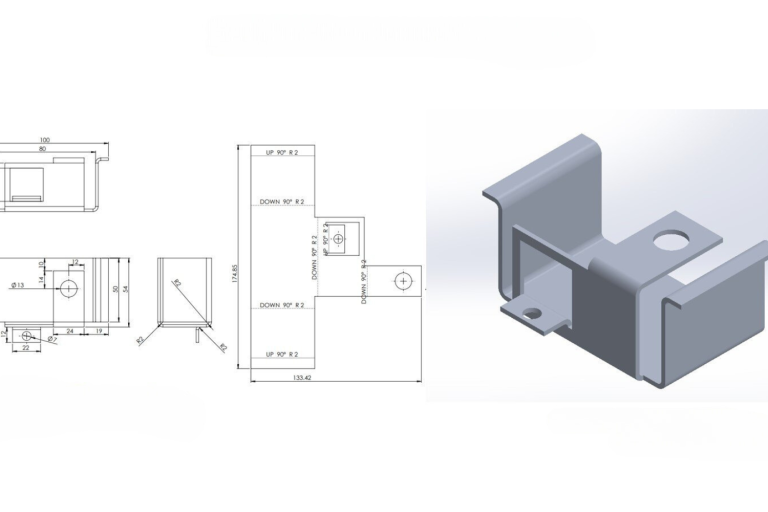

Another advantage of professional sheet metal design services is the ability to optimize the use of materials. By leveraging advanced design tools, such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, designers can ensure that sheet metal is used in the most efficient way possible. This results in parts that are lighter, more cost-effective, and yet still strong enough to perform under various conditions.

Through simulation and analysis, engineers can predict how sheet metal will behave under stress, such as heat, pressure, and vibration. This helps in selecting the right material thickness and type for the intended application, which directly contributes to both durability and performance. For example, in electronics, using the right gauge of sheet metal can protect internal components from environmental factors like moisture and dust while maintaining structural integrity.

3. Enhancing Corrosion Resistance

Corrosion is one of the most common issues affecting the durability of metal products. Sheet metal design services incorporate corrosion-resistant coatings and design strategies to prevent rust and deterioration, thereby increasing product longevity.

In industries like construction and aerospace, where metal parts are exposed to harsh environmental conditions, ensuring that the sheet metal components are resistant to corrosion is essential. Protective coatings, such as galvanization or powder coating, can be applied during the design phase, providing an added layer of protection against the elements. Additionally, designers can choose alloys that are naturally more resistant to corrosion, such as stainless steel, for specific applications.

4. Design for Manufacturability

Another critical aspect of sheet metal design services is ensuring that the product is not only durable but also easy to manufacture. Designing for manufacturability means that the sheet metal components can be produced in a cost-effective and efficient manner without compromising on quality. This involves factoring in the limitations of manufacturing processes, such as punching, bending, or welding, to ensure that the final product meets durability and performance requirements.

A well-designed sheet metal part is one that minimizes the need for rework or repairs during the manufacturing process, which leads to fewer defects and greater consistency in the final product. In turn, this contributes to a more reliable and durable end product.

5. Enhanced Performance Through Aerodynamic and Structural Optimization

For industries like automotive and aerospace, performance is equally as important as durability. Sheet metal design services help optimize the aerodynamic properties of products, which can lead to improved efficiency, fuel consumption, and overall performance. For instance, in the automotive sector, well-designed sheet metal components such as car hoods, side panels, and bumpers can contribute to a smoother airflow, reducing drag and improving vehicle performance.

In addition, structural optimization is essential for parts subjected to high stress. Sheet metal designers use simulation tools to ensure that components are both lightweight and structurally sound, enhancing the overall performance of the product while maintaining its durability. This approach is crucial for applications where the product must endure intense conditions, such as aerospace or heavy machinery.

6. Customization for Specific Needs

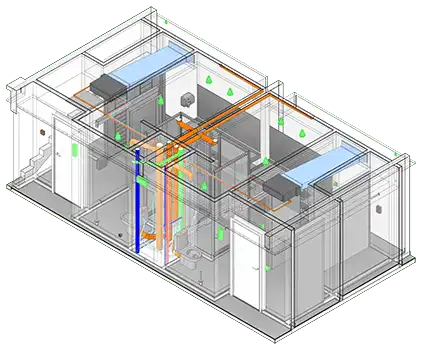

Sheet metal design services allow for customization based on the specific needs of the product, ensuring that each component is designed to enhance performance and durability. Whether it's creating custom brackets, enclosures, or panels, sheet metal design services enable the production of unique parts that meet exact specifications.

For example, in the electronics industry, custom sheet metal enclosures are often used to protect sensitive components from physical damage, electromagnetic interference, or heat. A well-designed enclosure can significantly extend the lifespan of electronic devices while maintaining optimal performance.

7. Sustainability and Recyclability

Sustainability is increasingly becoming a key factor in product development. Sheet metal is known for its recyclability, which means that it can be repurposed at the end of its lifecycle, reducing waste and promoting a circular economy. Through sustainable sheet metal design practices, products can be created with minimal environmental impact while still maintaining the highest standards of durability and performance.

By selecting recyclable materials and designing products that are easy to disassemble and recycle, sheet metal design services contribute to both environmental responsibility and long-term product viability.

Conclusion

Sheet metal design services are essential in creating products that not only meet but exceed durability and performance expectations. By leveraging precision engineering, optimizing material usage, enhancing corrosion resistance, and incorporating custom designs, these services provide a significant advantage in various industries. The ability to design for manufacturability, improve aerodynamics, and ensure sustainability further enhances the value of sheet metal components in product development.

For businesses seeking to create reliable, high-performance products, partnering with expert sheet metal design services is a smart choice. With the right design approach, sheet metal products can perform better, last longer, and deliver more value over time.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.