Step-by-Step Process of MEP BIM Coordination Services

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

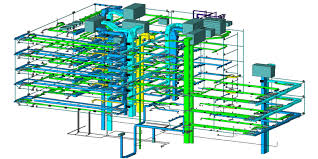

In today’s construction landscape, where timelines are tight and precision is non-negotiable, MEP BIM Coordination Services play a critical role. These services ensure that all Mechanical, Electrical, and Plumbing systems work in perfect harmony—avoiding costly on-site conflicts and delays. Let’s walk through the complete process that transforms fragmented MEP layouts into a coordinated and construction-ready BIM model.

Step 1: Collect Architectural and Structural Models

The process begins by collecting the architectural and structural base models from architects and civil engineers. These models form the digital skeleton of the project and serve as a reference for placing MEP components. This step ensures spatial alignment and helps teams understand the full scope of the project before MEP modeling begins.

✅ Goal: Build a reliable base model for accurate MEP integration.

Step 2: Create MEP System Models

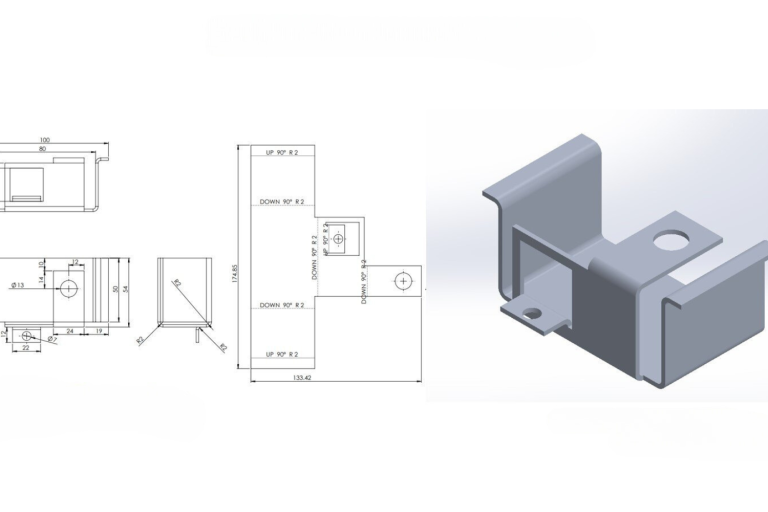

Next, 3D models of all MEP systems are developed using project drawings, specs, and industry standards. This includes HVAC ductwork, piping, sprinkler systems, electrical conduit, and plumbing lines. At this stage, the systems are drafted with consideration for available ceiling heights, shaft space, and routing logic.

🛠️ Software Tools: Revit MEP, AutoCAD MEP, Fabrication CADmep.

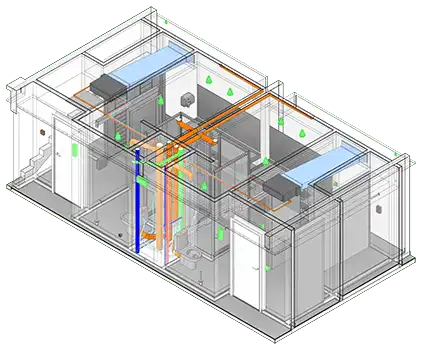

Step 3: Coordinate Between Trades

With all models in place, cross-discipline coordination begins. Each trade—mechanical, electrical, plumbing, and fire protection—shares its model with the team. Models are overlaid into a single federated BIM environment where overlaps and routing conflicts become visible.

🔄 Key Objective: Eliminate early-stage clashes before construction starts.

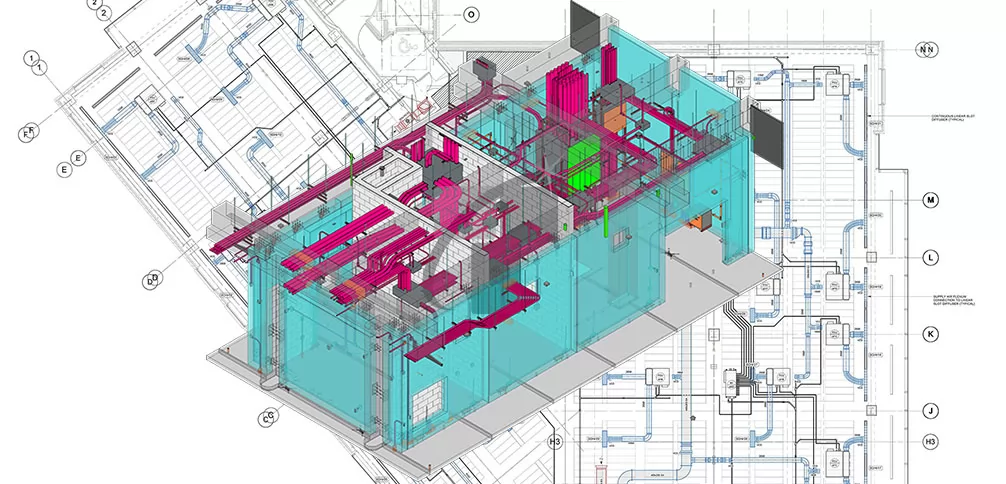

Step 4: Perform Clash Detection

Clash detection software like Navisworks is used to automatically identify conflicts between elements—such as ducts passing through beams or cable trays intersecting pipes. These clashes are categorized (critical, major, minor) and assigned for resolution.

🚫 Typical Clashes: Ductwork vs. structure, MEP vs. MEP, MEP vs. architectural components.

Step 5: Conduct Coordination Meetings

The clash reports generated are discussed in regular coordination meetings with project stakeholders. These collaborative sessions ensure clear communication and faster issue resolution. Decisions made here affect routing changes, design adjustments, or component resizing.

💬 Benefits: Better collaboration = fewer RFIs and site delays.

Step 6: Clash Resolution and Model Updating

Once all issues are identified and reviewed, models are revised accordingly. This step may involve re-routing ductwork, resizing pipes, or repositioning electrical elements. Updated models are checked again to confirm that all identified issues have been resolved.

🔧 Result: An optimized, clash-free, and buildable model.

Step 7: Final Approval and Sign-Off

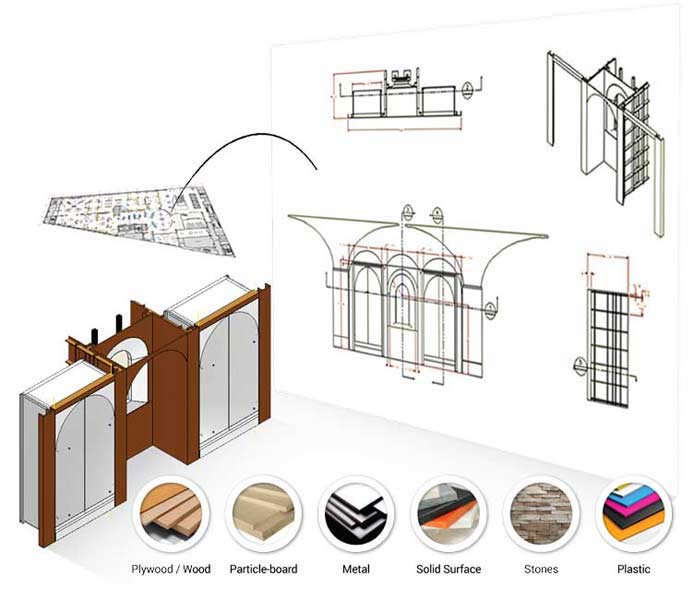

After thorough validation, the coordinated model is submitted for approval. This step involves getting sign-off from all involved trades and the general contractor. Once approved, this model serves as the base for generating construction and fabrication drawings.

📦 Deliverables: Coordinated MEP layouts, spool drawings, and installation plans.

Step 8: As-Built BIM Model (Optional)

For projects requiring post-construction accuracy, an as-built BIM model is developed. It captures any site changes made during installation and updates the model to reflect the final built condition. This model is invaluable for facility managers and long-term building maintenance.

🏢 Advantage: Serves as a digital twin for future renovations and operations.

Why It Matters

Without proper MEP coordination, clashes can lead to costly delays, on-site rework, and wasted materials. BIM-based coordination enables construction teams to avoid these issues entirely by resolving them virtually—before construction even begins.

Moreover, MEP BIM Coordination helps improve project transparency, reduce RFIs, and ensure smoother handovers between design and construction teams. Whether you're working on a hospital, airport, data center, or commercial high-rise, this process increases efficiency across the board.

Partner with the Experts

At Silicon Valley, we bring 20+ years of expertise in delivering precise and reliable MEP BIM Coordination Services across the USA and worldwide. Our team leverages tools like Revit MEP and Navisworks to deliver intelligent, clash-free models that make construction smoother and faster.

From MEP Coordination Drawing Services to Revit MEP BIM Modeling, we ensure every system fits—virtually and in real life.

📞 Ready to coordinate your project with confidence?

Let Silicon Valley help you achieve zero-clash construction. Contact us today for tailored MEP BIM solutions.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.