How to Choose the Right Die Cutting Method for Your Product Packaging

What is die cutting, and why does it matter for your packaging? Choosing the right die cutting method isn’t just a technical decision — it’s a strategic one. The type of die cutting you use affects everything from cost to design flexibility to turnaround time. Whether you're launching a new product or updating existing packaging, understanding the different die cutting methods can help you make the right choice. In this guide, we’ll walk you through each major type of die cutting, their pros and cons, and how to decide which is best for your needs.

Why Choosing the Right Die Cutting Method Matters

Each product has unique packaging needs. A custom jewelry box requires more intricate, precise cuts than a bulk mailer for promotional flyers. Choosing the wrong method could lead to wasted material, delays, or a poor customer experience.

At Custom Packaging Pro (CPP), we help businesses navigate these options to ensure their packaging is as effective and attractive as possible. Let’s explore the main die cutting techniques.

1. Manual Die Cutting

Manual die cutting machines are operated by hand and typically use steel-rule dies. They’re simple and cost-effective for low-volume jobs or prototypes.

Best For:

Small businesses and startups

Custom samples or test packaging

Short runs with simple shapes

Pros:

Low initial cost

Great for beginners

No need for expensive setup

Cons:

Limited speed and scalability

Less accurate for complex designs

2. Flatbed (Steel-Rule) Die Cutting

Flatbed die cutting uses heavy-duty dies and flat presses to stamp out shapes from thick materials. It's perfect for medium to large production runs.

Best For:

Corrugated and rigid boxes

Projects needing thicker materials

Standard or semi-complex shapes

Pros:

Durable and reliable

Ideal for repeated shapes

Handles thicker substrates

Cons:

Dies are more expensive to produce

Not suitable for ultra-fine details

3. Rotary Die Cutting

This technique uses cylindrical dies that rotate and cut as material feeds through the press. It’s fast and ideal for high-volume production.

Best For:

Large-scale production

Folding cartons

Labels and flexible packaging

Pros:

Extremely fast

Excellent for automation

Great for continuous cutting

Cons:

High equipment cost

Less flexibility with materials

4. Digital Die Cutting

Digital die cutting skips physical dies entirely. It uses software-controlled blades or lasers to create precise cuts. Perfect for custom work with quick turnaround.

Best For:

Prototyping and sampling

Variable designs

Quick, custom orders

Pros:

No die costs

Super-fast setup

Incredible design flexibility

Cons:

Slower for bulk jobs

May struggle with thicker materials

How to Choose the Right Method

Here are key factors to consider when selecting a die cutting method:

1. Project Volume

If you're producing thousands of units, rotary or flatbed methods are ideal. For short runs or prototypes, manual or digital will be more cost-effective.

2. Design Complexity

For highly detailed or custom-shaped packaging, digital die cutting offers the most flexibility. Simple shapes can be handled well with manual or flatbed methods.

3. Material Type

Thicker materials like corrugated board need steel-rule dies (flatbed). Thin materials or flexible stock can work well with rotary or digital cutting.

4. Budget

Digital die cutting eliminates tooling costs but can cost more per unit for large runs. Manual is the cheapest upfront, while flatbed and rotary require investment in dies.

5. Turnaround Time

Digital is fastest to start since no die needs to be made. Rotary is fastest for mass production. Manual and flatbed fall in between.

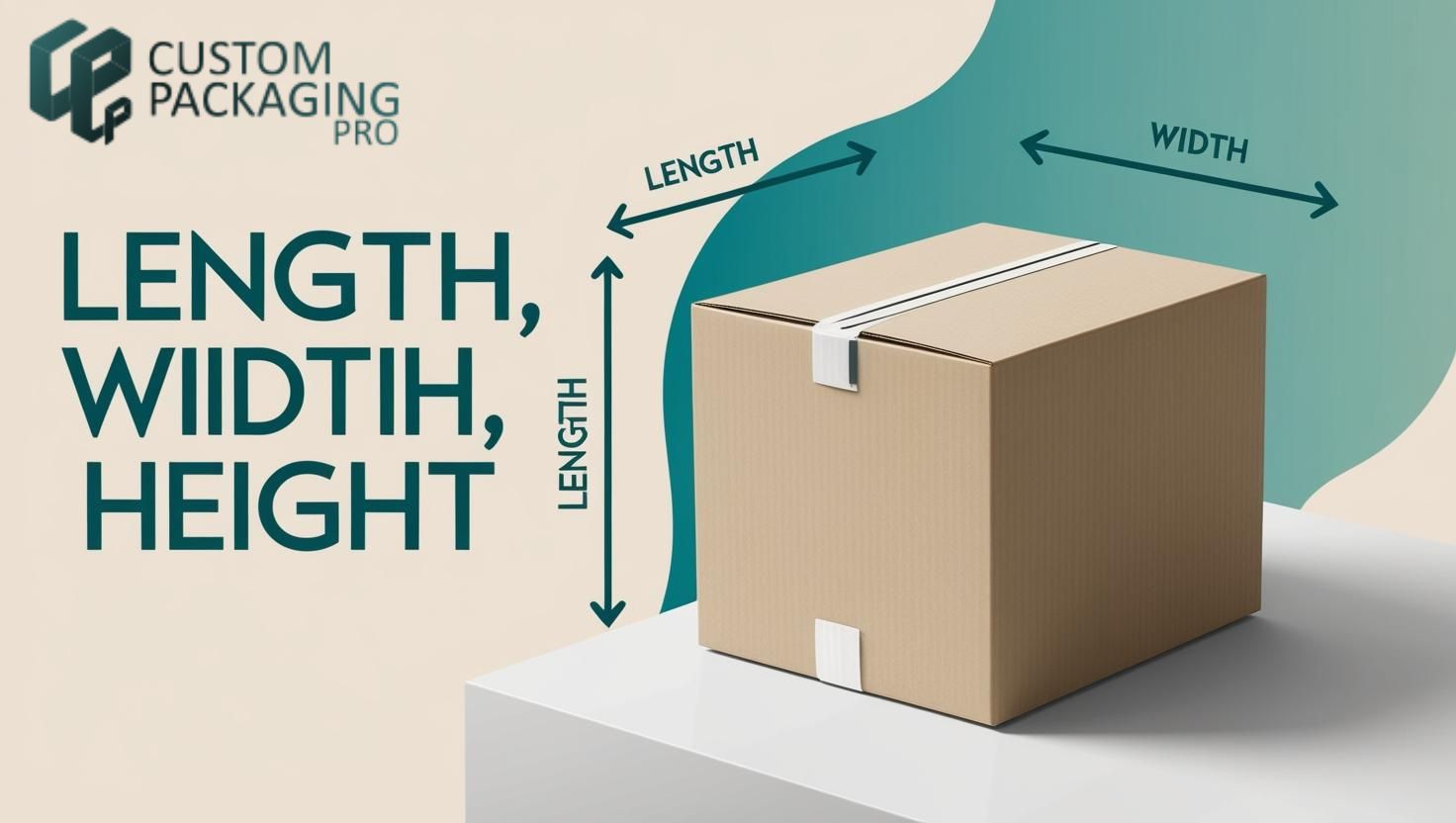

Measuring for Die Cut Packaging

Accurate measurements are crucial, regardless of method. Always calculate using the formula:

Length x Width x Height

At CPP, we assist our clients in properly measuring and translating these dimensions into dielines that ensure a perfect fit.

FAQs

Q: What if I only need a small batch of boxes?

A. Go with digital die cutting. It's affordable, fast, and doesn’t require physical tooling.

Q: Can I use the same dieline for different cutting methods?

A. Yes, but adjustments might be needed depending on material thickness and tolerance levels.

Q: How do I know which material is compatible?

A. Talk to your packaging partner. At CPP, we evaluate your design, volume, and material to recommend the best match.

Q: Are digital cuts as precise as steel-rule cuts?

A. In most cases, yes — especially for short runs. For very thick or layered materials, steel-rule may still be more accurate.

Conclusion

Understanding what die cutting is and choosing the right method depends on your packaging goals, product type, and budget. From prototyping with digital blades to scaling production with rotary systems, there’s a method to suit every need.

At Custom Packaging Pro (CPP), we guide clients from concept to completion, ensuring every package is functional, on-brand, and production-ready. Choosing the right die cutting method is easier when you have the right team behind you.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.