Why Accurate Length, Width, Height Measurements Matter in Packaging

In the world of product packaging, few things are more important than getting the measurements right. Whether you're shipping a delicate item or displaying retail-ready goods, dimensions such as length width height determine everything from cost-efficiency to shelf appeal.

At Custom Packaging Pro, we believe that precision in packaging is not just a technical requirement — it's a business advantage. In this post, we’ll break down why these basic dimensions matter so much, how to measure correctly, and what pitfalls to avoid when designing custom boxes.

Why Length, Width, and Height Are More Than Just Numbers

When packaging is created for a product, the three essential dimensions—length, width, and height—define the internal space, the structural integrity, and the outward appearance of the box. These numbers impact:

Material usage and cost

Shipping rates and logistics

Brand presentation and shelf placement

Product safety and fit

Getting them wrong can lead to under-sized or oversized boxes, increased shipping costs, and even product damage. In contrast, getting them right results in better protection, lower expenses, and higher customer satisfaction.

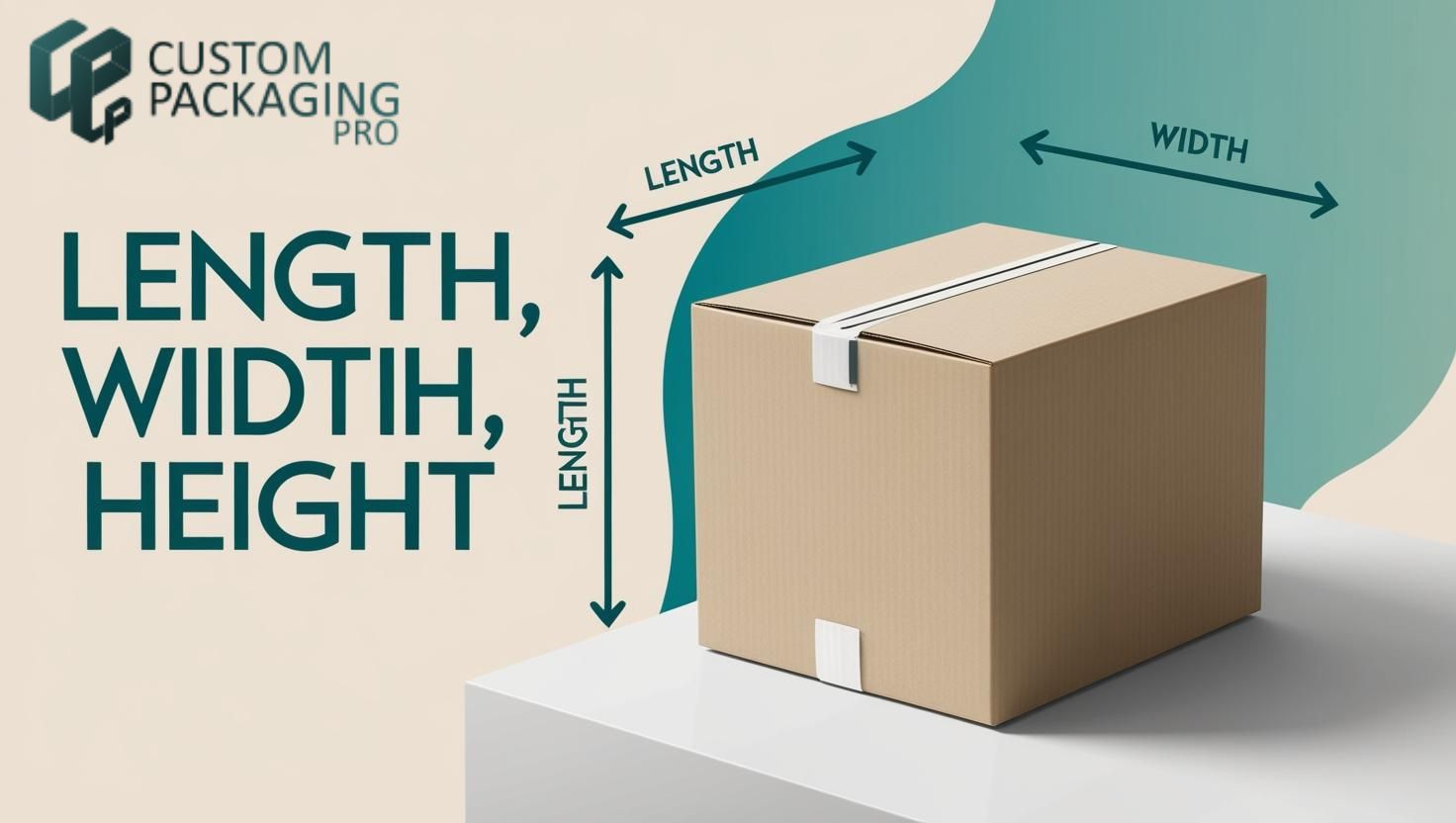

Understanding the Basics: What Do Length, Width, and Height Mean?

Many people use these terms interchangeably, but in packaging, each dimension has a specific meaning:

Length: The longest side of the box when it's facing you.

Width: The shorter side, from left to right.

Height (or Depth): How tall the box stands from base to top.

So, if you're measuring a rectangular box for a cosmetic product, for example, the length might be 6 inches, width 3 inches, and height 2 inches.

At Custom Packaging Pro, we guide clients through this process, helping them avoid confusion and ensuring that their packaging fits like a glove.

The Role of Precise Measurements in Custom Box Design

Accurate dimensions are crucial in custom box manufacturing. Here’s how:

1. Material Efficiency

If the box is even an inch too big, you’re wasting cardboard and paying extra for unnecessary materials. Over time, that adds up—especially in bulk orders.

2. Shipping Cost Optimization

Most carriers use dimensional weight pricing, which considers the length, width, and height of your package rather than just its actual weight. Small measurement mistakes could push your package into a more expensive pricing tier.

3. Product Protection

A snug fit minimizes movement inside the box, protecting fragile items. With perfect dimensions, your product arrives intact and professional-looking.

Measuring Your Product the Right Way

To measure accurately, follow these simple steps:

Start with a hard ruler or tape measure.

Measure the length: the longest side of the product.

Measure the width: the shorter side.

Measure the height: from base to top.

Tip: Always use inside dimensions when designing your custom packaging to ensure the product fits perfectly within the box.

Custom Packaging Pro provides dielines and 3D mockups for your product packaging based on the exact measurements you provide. We also offer support if you’re unsure how to measure correctly.

Industry-Specific Examples: Why Measurements Matter

E-commerce Packaging

Online sellers must balance product safety and cost. A difference of half an inch in height or width can significantly change fulfillment fees, especially with third-party logistics providers.

Food Packaging

Packaging for items like baked goods or pasta requires precision to prevent squishing or movement. Accurate length, width, height dimensions also keep presentation consistent.

Cosmetic & Retail Boxes

A luxury lotion bottle or a custom-designed soap bar needs packaging that complements its design. A poor fit not only risks damage but also diminishes brand perception.

How Custom Packaging Pro Simplifies the Process

At Custom Packaging Pro, we don’t expect you to be an expert in box design. That’s our job. Here’s how we help:

Free box templates and measurement guides

Live support for product measuring

3D design previews with accurate dimensions

Auto-adjustments for product movement or padding

We ensure that your box’s length, width, and height are not just numbers — they’re a core part of your brand identity.

Common Mistakes to Avoid

Here are a few packaging pitfalls we help clients steer clear of:

Confusing height with length: This can distort your box design.

Measuring with loose tape: Even a small difference can create fitting problems.

Using outside box dimensions: Always rely on internal dimensions for design.

We believe packaging should be effortless and error-free, which is why our team at Custom Packaging Pro double-checks every order before going to print.

Measurement-Based Packaging Keywords to Know

If you’re searching for packaging help or SEO-targeting terms, here are some common phrases tied to box measurement:

Custom box dimensions

Length width height of shipping box

How to measure packaging box

Correct box size for product

Internal box measurements

These keywords are not just for SEO—they help businesses find accurate solutions for their packaging needs. That’s exactly what Custom Packaging Pro delivers.

Final Thoughts: Precision Means Power in Packaging

No matter what industry you’re in, getting your length, width, and height right is one of the most valuable steps in custom packaging. It affects your budget, brand image, and customer experience.

At Custom Packaging Pro, we empower businesses with customized, perfectly measured packaging solutions that meet real-world needs. From small startups to established brands, we’re here to help you turn your dimensions into a packaging success story.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.