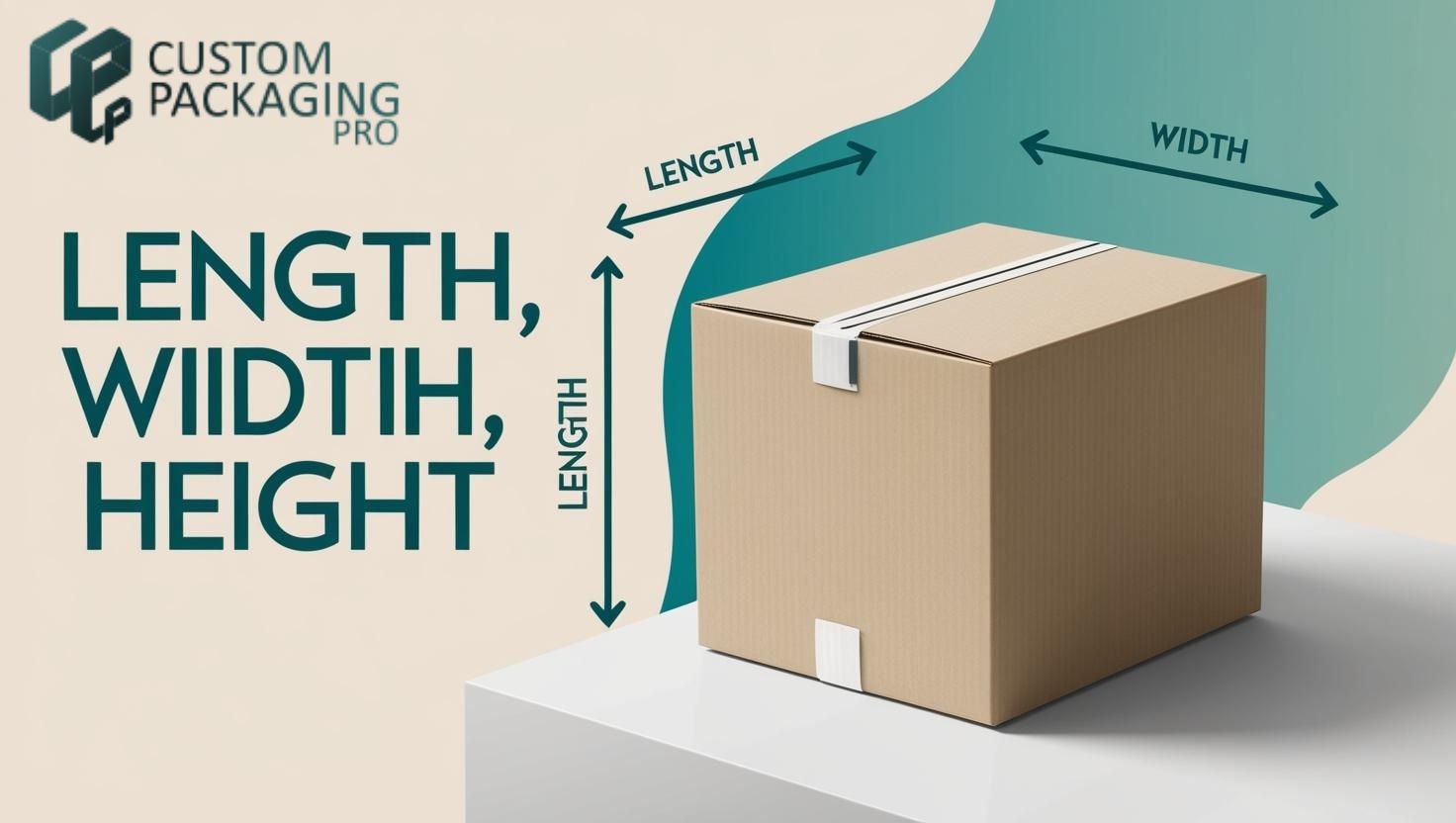

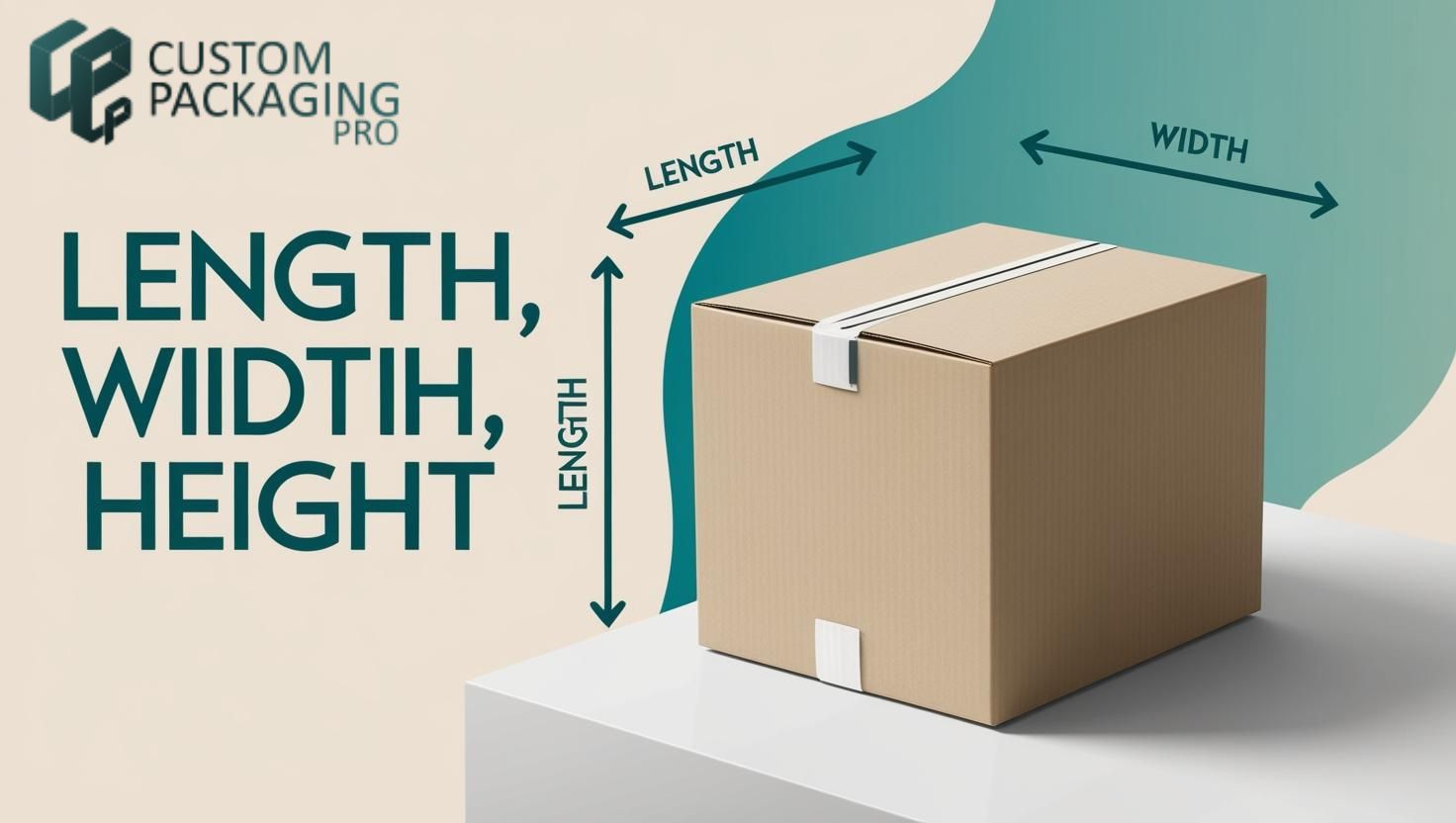

How to Measure Length, Width, and Height for Perfectly Fitting Packaging Boxes

When it comes to packaging, the most critical factor for a successful product shipment is ensuring that your product fits perfectly inside the box. Whether you're a small business owner or part of a large enterprise, understanding how to measure length width height for your packaging boxes is vital. Properly measured packaging helps save on material costs, reduces damage during shipping, and enhances the overall customer experience.

In this article, Custom Packaging Pro will guide you step-by-step on how to measure your product and select the right packaging box to ensure a perfect fit. We'll also touch on the importance of accurate measurements for various industries, from e-commerce to retail. By the end of this article, you'll be well-equipped with the knowledge to measure and choose the ideal packaging box for your products.

Why Accurate Measurements Matter in Packaging

Choosing the right box size for your product can affect multiple aspects of your business, including cost, product protection, and customer satisfaction. Here’s why accurate measurements matter:

Cost Efficiency: Over-sized boxes require more packing materials (like bubble wrap or filler) and increase shipping costs. Conversely, using a box that's too small can damage your product, leading to returns and customer dissatisfaction. A perfectly fitting box reduces the need for excess materials and saves on shipping costs.

Product Protection: A box that’s too big or too small increases the risk of damage during transit. Products may move inside the box if there’s too much space or they could be squashed if there’s not enough. A custom-fit box from Custom Packaging Pro ensures that your product stays in place and is properly protected.

Sustainability: Packaging plays a key role in sustainability efforts. A box that is the right size reduces waste and supports environmental sustainability by limiting the amount of packaging material used.

Brand Perception: Perfectly fitting boxes show your customers that you care about both your product and their unboxing experience. It communicates professionalism and attention to detail, reinforcing your brand identity.

Step-by-Step Guide: How to Measure for the Perfect Packaging Box

Step 1: Measure the Length of Your Product

The length is typically the longest dimension of your product. To measure the length, use a measuring tape or ruler to determine the distance from one end of your product to the other, ensuring that the product is lying flat when you measure.

For irregular shapes: If your product is not uniform, like a bottle or a custom-shaped item, you should measure the longest part of the product, including any protrusions (like a pump on a bottle or a lid).

Pro Tip: Always round up the measurement slightly. This ensures the box isn't too tight, giving a little room for protective packing materials.

Step 2: Measure the Width of Your Product

The width is the shorter side of your product. Just as with length, measure from one side to the other. When measuring width, it’s important to account for any side extensions such as handles or buttons that may increase the overall width of the product.

For oddly shaped products: Measure at the widest point, ensuring that the packaging box will accommodate the item properly.

Step 3: Measure the Height of Your Product

The height refers to how tall your product is when it is standing upright. If your product is rectangular, measuring the height is straightforward. However, if your product has an irregular shape (like a cone or cylindrical object), measure from the base to the top, accounting for any contours or uneven areas.

Pro Tip: If your product has a lid or additional parts that may shift or extend, account for this extra height to ensure everything fits comfortably.

Step 4: Consider Additional Elements for Packaging

While length, width, and height are the primary dimensions of your packaging box, other factors such as weight, fragility, and product orientation may impact your packaging choices. Here are some additional elements to consider:

Weight: A heavier product may require sturdier materials and reinforced boxes to prevent damage during shipping.

Fragility: If your product is delicate, use cushioning materials like foam inserts, bubble wrap, or packing peanuts to keep your product safe. Always consider how much extra space you’ll need for protective materials.

Product Orientation: Ensure the packaging box allows for proper placement of the product. If your item needs to be positioned in a specific way (for example, upright or on its side), make sure the box design allows for that positioning without shifting.

How to Select the Right Packaging Box Based on Your Measurements

After measuring your product's length, width, and height, you can begin the process of selecting the right box. Here’s how:

Choose Box Type: Packaging boxes come in different shapes and styles. Select the box style that suits your product's shape. For example:

Regular Slotted Containers (RSC): Perfect for rectangular products.

Mailer Boxes: Ideal for flat products like books, art, or clothing.

Rigid Boxes: Often used for premium products or fragile items.

Add Cushioning: Once you've chosen a box size, you’ll need to add cushioning materials such as bubble wrap, foam, or kraft paper to protect the product during shipping.

Use Adjustable Boxes: Some brands use adjustable boxes that can be resized for different products, allowing flexibility in packaging.

Customization: Consider customizing your box with your brand’s logo or design to give your packaging a unique and professional look. Custom Packaging Pro offers custom packaging solutions that enhance your product’s presentation while providing the perfect fit for your product.

What Are the Common Mistakes to Avoid When Measuring Packaging Boxes?

Accurately measuring packaging boxes may seem simple, but there are a few common mistakes that can lead to poor packaging decisions:

Not Accounting for Extra Space: If you don’t leave enough space for cushioning, your product may not be adequately protected. Always factor in some space for padding.

Measuring Without Including Protruding Elements: Some products have elements that stick out, such as handles or caps. Make sure to measure these parts as well.

Choosing the Wrong Box Shape: Some shapes are harder to fit into certain boxes, so ensure that you pick the right box style for your product.

Not Rounding Up Measurements: Never round down when measuring. If your product is 6.5 inches, choose a box that’s at least 7 inches. This ensures that there’s adequate space for protective materials and prevents damage during shipping.

FAQs About Measuring Packaging Boxes

Q1: How do I measure for a custom box?

To measure for a custom box, follow the same steps for length, width, and height. After that, work with Custom Packaging Pro to design a box that matches your measurements and includes any special features like custom shapes or additional protection.

Q2: Can I use a box that’s too large for my product?

While you can use a larger box, it may increase shipping costs and require more filler materials. A perfectly fitting box from Custom Packaging Pro reduces both costs and risk of damage.

Q3: How can I ensure my packaging is eco-friendly?

Look for boxes made from recycled materials, biodegradable fillers, and sustainable inks. Custom Packaging Pro offers eco-friendly packaging solutions that not only help the environment but also appeal to environmentally conscious customers.

Conclusion

Getting the right size packaging box for your products is more than just about fitting the item inside. Properly measured packaging helps protect your product, ensures cost-efficiency, and enhances customer satisfaction. By following the steps outlined in this article, you can confidently measure length, width, and height for your products and choose the right packaging that fits perfectly.

If you're unsure about any part of the process, don’t hesitate to consult with Custom Packaging Pro who can offer guidance and even create custom solutions for your products.

Start measuring accurately today to take your packaging to the next level!

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.