How to Ensure Quality in Your Aluminum Foundry Service

The aluminum foundry sector is important to manufacturing since it supplies parts for consumer, automotive, and aerospace products. Upholding high standards of quality is important for the finished goods' functionality, robustness, and safety. In foundries, internal control includes careful inspection procedures, accurate casting procedures, and staple selection. To ensure mechanical qualities, corrosion resistance, and dimensional precision, premium aluminum alloys, sophisticated casting processes, and routine inspections are necessary.

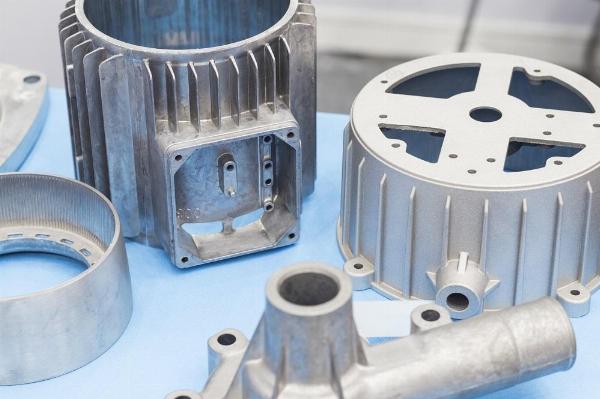

Understanding Aluminum Foundry Processes

aluminum foundries use sand casting, die casting, and investment casting to create high-quality castings. These procedures are selected consistently with certain specifications, like manufacturing volume, surface polish, and accuracy. Common aluminum alloys are the 300 series, which resist corrosion, and therefore the 600 series, which are strong and weldable. A variety of elements, including cooling rate, casting technique, and purity, affect the standard of aluminum castings. While regulated cooling rates reduce internal tensions and enhance dimensional correctness, high-purity aluminum minimizes flaws. For completed components to be dependable and long-lasting, proper procedures for acquiring aluminum resources must be followed. Services provided by Aluminum Foundry service are vital to manufacturing because they supply lightweight, corrosion-resistant parts that are needed in sectors including electronics, automotive, and aerospace.

Importance of Fabric Selection

In manufacturing, choosing the proper materials is important, particularly when it involves aluminum. The purity, mechanical qualities, and corrosion resistance of high-quality aluminum directly impact the performance of the finished product. Aluminum's capacity to tolerate stress and strain is greatly influenced by its lastingness and ductility. To make sure the chosen aluminum satisfies the actual needs of the planned application, careful consideration of those factors is important.

Implementing internal control Measures

The integrity of aluminum castings depends on internal control procedures at foundries. This contains qualitative analysis, visual inspections, non-destructive testing, and strict monitoring and testing. Following industry certifications like ISO 9001 guarantees that the standard satisfies predetermined standards, improving product dependability and inspiring consumer trust within the production process. This methodical technique improves the dependability of the output.

Investing in Technology and Equipment

Purchasing cutting-edge machinery and technology is important to enhancing aluminum foundry services. Precision CNC machines and automatic casting systems are samples of advanced technology that improves internal control, lowers human error, and boosts productivity. Lead times are shortened, and reliable production results are achieved via the mixing of automation and manufacturing processes. Increased market competitiveness, reduced operating expenses, and better product quality are among the benefits. Foundries are ready to satisfy customer requests while upholding strict quality requirements. Because they will accurately construct complicated shapes, an Aluminum Investment Casting Foundry is essential for lowering material waste and increasing production efficiency.

Skilled Workforce and Training

Because it has an immediate influence on production efficiency and quality, skilled personnel are important to the foundry process. Continuous education and training initiatives improve individual skills and support operational excellence. Understanding customer needs and managing production steps require clear communication and teamwork. Reliable supply chains and quality assurance are ensured by cultivating strong connections with suppliers. It's crucial to cultivate a culture of quality among employees, which can be accomplished through frequent training sessions, ownership encouragement, and feedback systems. Setting these tactics as a top priority creates a perfect atmosphere where everyone values quality.

Effective Communication and Collaboration

To ensure alignment with project goals and quality standards, the foundry sector relies heavily on effective communication and collaboration. Open lines of communication make it easier to share information, and dealing with clients allows you to raise understand their needs and adjust procedures accordingly. Strengthening ties with suppliers enhances the dependability and quality of the materials.

Regular Maintenance

In the foundry industry, routine maintenance is important since it affects both product quality and manufacturing efficiency. Regular procedures like inspections and repairs reduce the prospect of kit failure, improve product dependability, and match quality standards, all of which increase production efficiency. Aluminum casting solutions are essential for creating high-quality components, recycling scrap, and ensuring sustainable, economical manufacturing—all of which boost market competitiveness and innovation.

Customer Feedback and Continuous Improvement

For foundries to know about the standard of their products and pinpoint areas for development, customer input is important. A methodical strategy that comes with surveys and interviews aids in the development of focused plans, improving the standard of products, cultivating client loyalty, and boosting company performance.

Conclusion

The success of the aluminum foundry sector depends on the caliber of its castings, which affects dependability and performance. Long-term success depends on putting strict internal control procedures in situ, which promotes client happiness and environmentally friendly corporate operations.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.