Transforming Aluminum Alloys to Chemical Conversion Coating

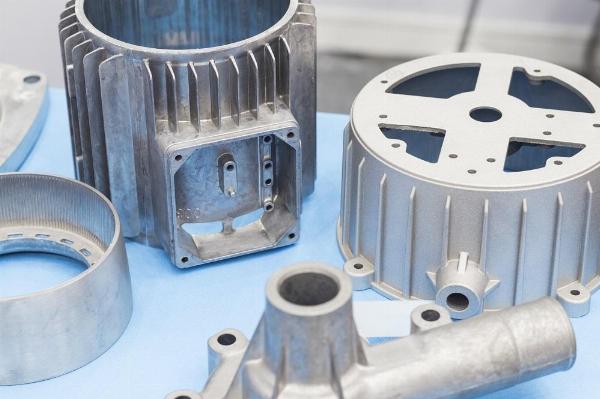

Aluminum alloys are prized for their lightweight yet durable properties, making them a top choice in industries like aerospace, automotive, and construction. But did you know that these materials can be further enhanced? Enter chemical conversion coatings—a fascinating process that not only improves the strength and longevity of aluminum alloys but also adds a layer of corrosion resistance.

What is Chemical Conversion Coating?

Chemical conversion coating is a treatment method applied to metals during aluminum casting services, including aluminum alloys, to improve their surface properties. This process involves a chemical reaction between the metal surface and a chemical solution, resulting in a protective layer that enhances corrosion resistance. Unlike other coatings, chemical conversion coatings are integrated into the metal's surface, offering more robust and long-lasting protection.

The Science Behind It

The science of chemical conversion coatings revolves around the interaction between the aluminum alloy and the chemical bath. When aluminum alloys are immersed in the solution, a thin film forms on the surface due to a chemical reaction. This film acts as a barrier against environmental factors like moisture and oxygen, which can cause corrosion.

Types of Chemical Conversion Coatings

There are various types of chemical conversion coatings, each suited for specific applications. The most common types include chromate, phosphate, and anodizing. Chromate coatings are known for their excellent corrosion resistance, while phosphate coatings are often used as a base for further painting. Anodizing, on the other hand, not only protects but also allows for dyeing the surface, adding aesthetic value.

Why Choose Chemical Conversion Coating?

Chemical conversion coatings offer several advantages over other protective methods. They are cost-effective, easy to apply, and provide excellent adhesion for additional layers like paint or powder coating. Furthermore, these coatings are environmentally friendly, with some types even meeting stringent environmental regulations.

Benefits of Chemical Conversion Coating

Here are some of the most significant advantages:

- Enhanced Corrosion Resistance

One of the primary reasons for applying chemical conversion coatings is to improve corrosion resistance. The protective layer formed during the process acts as a barrier, preventing corrosive elements from penetrating the metal surface.

- Improved Paint Adhesion

Another notable benefit is the improved adhesion for subsequent coatings. Whether you're an error occurred during generation. Please try again or contact support. using paint, powder coating, or adhesive bonding, chemical conversion coatings provide a strong base that promotes adhesion and increases the durability of the final product.

- Cost Savings

Compared to other methods like electroplating or anodizing, chemical conversion coatings are significantly more cost-effective. The process requires fewer steps and equipment, making it a popular choice for those looking to reduce production costs.

- Versatility

Chemical conversion coatings can be applied to various metal substrates, including aluminum alloys. This versatility allows for their use in different industries and applications without compromising on quality or effectiveness.

Real-World Applications of Chemical Conversion Coatings

Chemical conversion coatings find widespread use in various industries and applications. Some notable examples include:

- Automotive Industry

The automotive industry utilizes chemical conversion coatings to protect aluminum alloys used in car bodies, engines, and components from corrosion. These coatings also enhance the adhesion of paint and other surface finishes.

- Aerospace Industry

Aircraft manufacturers utilize chemical conversion coatings to treat aluminum alloys used in airframes, landing gear components, and engine parts. The added corrosion resistance is crucial for ensuring the safety and durability of these critical components.

- Construction Industry

In the construction industry, chemical conversion coatings are applied to aluminum structures like windows, doors, and curtain walls to protect against corrosion from exposure to the elements. This also helps these structures maintain their aesthetic appeal for longer periods of time.

- Electronics Industry

Chemical conversion coatings are also used in the electronics industry by custom aluminum product manufacturers to enhance the corrosion resistance of aluminum components like computer casings and mobile phone frames. These coatings can also improve electrical conductivity, making them ideal for electronic applications.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.