Top Tips for a Smooth Aluminum Casting Assembly

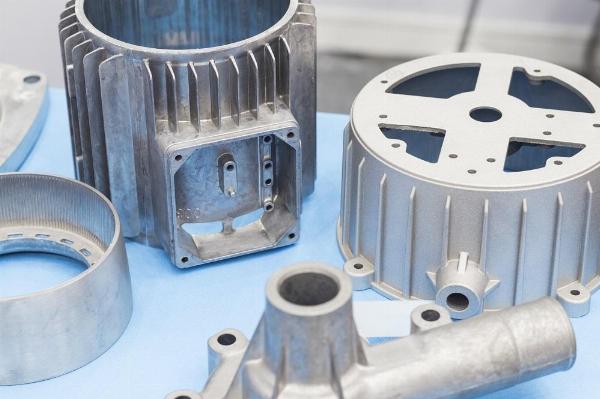

A common manufacturing technique is aluminum casting, which entails creating different components by pouring molten metal into a mold. Numerous benefits accompany this procedure, like its affordability, adaptability, and capacity to make intricate forms. It's frequently employed in sectors including construction, aerospace, and automotive.

In aluminum casting, a smooth assembly procedure is important to guarantee the integrity and quality of the finished product. The general performance and safety of the component could also be jeopardized by structural weaknesses resulting from any gaps or flaws within the assembly. Manufacturers will reduce the likelihood of errors, boost customer happiness, and increase product dependability by concentrating on a smooth assembly process.

Because aluminum casting is versatile and affordable, it's used extensively in many sectors. A smooth assembly process is crucial to ensuring the top product's functionality and quality. It's vital for manufacturers to consistently endeavor to reinforce their assembly methods to satisfy the growing market needs and guarantee client contentment. Consider taking expert advice and guidance from an aluminum casting supplier to learn about the best tips.

Preparation for Aluminum Casting Service

It's important to get ready for aluminum casting assembly services with an aluminum casting prototype manufacturer. Planning everything in detail is crucial. It guarantees a seamless and effective procedure. Making the proper choices is crucial when it involves tools and equipment. This guarantees precision and accuracy during the assembling process. Having a well-organized workstation is additionally essential. It makes equipment and supplies easily accessible, lowering the likelihood of mishaps and increasing output.

Material Selection for Aluminum Casting

An important thing about aluminum casting assembly services is material selection. Selecting an acceptable aluminum alloy is crucial. The qualities of various alloys vary, including heat conductivity, strength, and corrosion resistance. To get the intended outcomes, it's essential to grasp these material qualities. It is also critical to consider environmental elements. Aluminum is a sustainable material choice for casting assembly services since it's recyclable.

Mold Design in Aluminum Casting

An essential component of aluminum casting assembly services is mold design. Important guidelines that guarantee successful casting results function as a basis for effective mold design. Channels for cooling and venting are essential for preserving the cast components' quality. Additionally, the top product's functioning and appearance are influenced by the mold's surface polish.

Casting Process

There are a variety of approaches to be considered when it involves the casting process for aluminum assembly services. These contain die casting, sand casting, and other methods. Every approach has pros and cons of its own. To achieve the simplest results throughout the casting process, temperature management is crucial. The control of the pouring processes additionally influences the entire effectiveness of the casting process.

Quality Control in Aluminum Casting

Quality control is crucial when it involves aluminum casting assembly services. Fixing inspection criteria is important to guarantee that the finished product meets the required requirements. This entails closely inspecting every part to see for flaws or irregularities. The utilization of non-destructive testing methods is crucial to the present procedure since they supply in-depth analysis without inflicting any harm. Manufacturers can find trends and take the specified action to boost the overall caliber of their assembly services by tracking and recording faults.

Assembly Techniques

Careful thought must be put into assembly methods for aluminum casting assembly services. The simplest practices for combining cast components include choosing the proper technique, like mechanical fasteners or adhesives. Mechanical fasteners provide a firm connection, whereas adhesives offer a robust binding with flexibility. Fit and alignment are also essential components to ensure a successful assembly. A strong and dependable finished product is produced when the components fit together perfectly, which is ensured by proper alignment.

Finishing Touches

The final touches for aluminum casting assembly services are crucial to improving the product's use and appearance. Two popular finishing methods used to increase durability and achieve desired surface finishes are coating and machining. Enhancing the mechanical qualities of the assemblage also requires post-casting procedures like heat treatment or surface hardening. Manufacturers need to be very careful about whether the finish is merely for show or whether it's to satisfy certain practical specifications. By listening to those finishing details, manufacturers can deliver high-quality aluminum casting assembly services that meet the requirements and expectations of their customers.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.