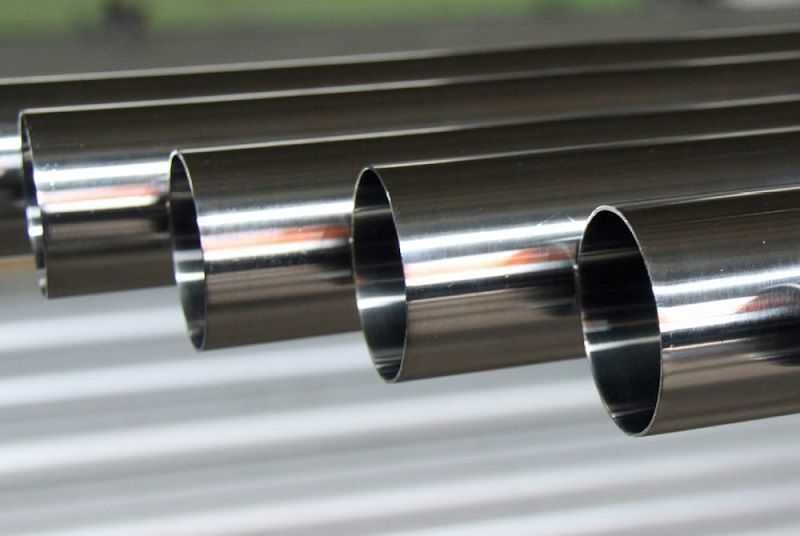

Nickel 200 Fasteners: The Best Choice for Oil and Gas Applications

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In the demanding world of oil and gas, the choice of fasteners can significantly impact the performance and longevity of equipment. Nickel 200 Fasteners are often considered the top choice for such applications due to their exceptional properties and reliability under harsh conditions. This blog explores why Nickel 200 Fasteners are ideal for oil and gas applications and how they stand out in the industry.

1. Superior Corrosion Resistance

One of the most critical factors in the oil and gas industry is the resistance of materials to corrosion. The environment in this sector often involves exposure to corrosive substances such as chemicals, acids, and brine. Nickel 200 Fasteners excel in these conditions due to their inherent corrosion resistance. Nickel 200 is composed of 99.6% pure nickel, which offers excellent resistance to a wide range of corrosive agents. This property ensures that the fasteners maintain their structural integrity and functionality even in harsh chemical environments, reducing the need for frequent replacements and minimizing maintenance costs.

2. High-Temperature Stability

Oil and gas operations frequently involve high-temperature environments, whether in drilling operations or refinery processes. Nickel 200 Fasteners are known for their ability to withstand elevated temperatures without losing their mechanical properties. Unlike some materials that become brittle or lose strength at high temperatures, Nickel 200 maintains its stability and performance. This thermal stability is crucial for preventing failure and ensuring the safety and efficiency of equipment used in high-heat conditions. The ability of Nickel 200 Fasteners to handle temperatures up to approximately 1,200°F (650°C) makes them a reliable choice for these demanding applications.

3. Excellent Mechanical Properties

Mechanical properties such as tensile strength and ductility are vital for fasteners used in high-stress environments. Nickel 200 Fasteners are valued for their robust mechanical properties, including high tensile strength and good ductility. These characteristics ensure that the fasteners can withstand significant mechanical stresses and pressures without deforming or breaking. This is particularly important in the oil and gas industry, where fasteners must support heavy loads and resist mechanical forces that could otherwise lead to equipment failure.

4. Resistance to Stress Corrosion Cracking

Stress corrosion cracking (SCC) is a common issue in many industrial applications, particularly when materials are exposed to high stress and corrosive environments. Nickel 200 Fasteners offer excellent resistance to SCC, which enhances their reliability and longevity. This resistance is crucial for maintaining the safety and integrity of equipment, as it prevents the development of cracks that could lead to catastrophic failures. By choosing Nickel 200 Fasteners, companies can avoid the risks associated with SCC and ensure the durability of their equipment.

5. Versatility in Application

The versatility of Nickel 200 Fasteners makes them suitable for a wide range of applications within the oil and gas industry. Whether used in pipelines, drilling equipment, or other critical components, these fasteners provide dependable performance. Their ability to adapt to various settings and conditions contributes to their widespread use in the industry. This versatility means that Nickel 200 Fasteners can be used in multiple types of equipment, providing a consistent solution across different applications.

6. Cost-Effectiveness

While the initial cost of Nickel 200 Fasteners may be higher compared to some other materials, their long-term benefits make them a cost-effective choice. The durability and resistance properties of Nickel 200 Fasteners lead to reduced maintenance and replacement costs over time. Their ability to withstand harsh conditions without frequent failures means that companies can save on repair and replacement expenses, making them a wise investment in the long run.

Conclusion

Nickel 200 Fasteners are an excellent choice for the oil and gas industry due to their superior corrosion resistance, high-temperature stability, robust mechanical properties, and resistance to stress corrosion cracking. Their versatility and cost-effectiveness make them a reliable option for ensuring the performance and longevity of critical equipment. By choosing Nickel 200 Fasteners, companies can enhance the safety, efficiency, and durability of their operations, making them a top choice for demanding industrial applications

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.