Pick to Light Systems: Revolutionizing Inventory Management

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

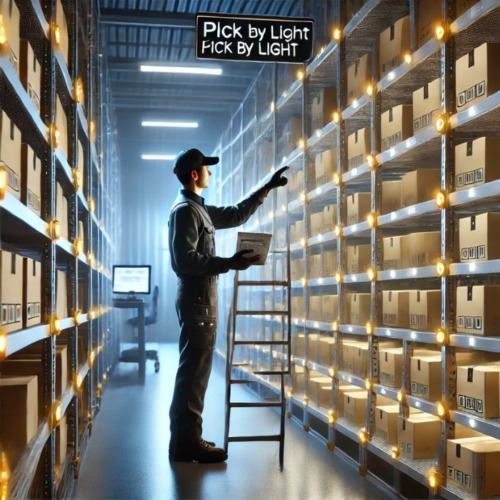

In today's fast-paced, tech-driven supply chain environment, companies are constantly seeking ways to improve efficiency, reduce errors, and enhance productivity. One of the most impactful innovations in this space is the Pick to Light System—a revolutionary approach to inventory management that is transforming how warehouses and fulfillment centers operate.

What is a Pick to Light System?

A Pick to Light System is a semi-automated picking solution that uses LED lights and digital displays to guide workers to the correct picking location in a warehouse. When an order is received, the system illuminates the appropriate storage bin or shelf with a light and display indicating the quantity to be picked. Workers simply follow the lights and confirm their picks, streamlining the entire order fulfillment process.

Unlike traditional methods that rely on paper-based systems or handheld scanners, pick to light systems eliminate guesswork and significantly reduce the chances of human error.

Why Warehouses are Embracing Pick to Light Technology

1. Increased Speed and Efficiency

The primary advantage of using a pick to light system in warehouse settings is the drastic improvement in picking speed. By guiding workers directly to the right bin, these systems eliminate the time wasted searching through inventory. This is particularly valuable in high-volume fulfillment centers where time is of the essence.

2. Accuracy and Error Reduction

Manual picking processes are prone to errors, which can result in customer dissatisfaction, returns, and lost revenue. With a Pick to Light System, the chance of picking the wrong item is significantly reduced, as workers are visually directed to the correct location and quantity.

3. Scalability and Flexibility

Pick to light systems are modular and scalable, making them ideal for businesses of all sizes. Whether you're managing a small warehouse or a large distribution center, the system can be expanded or modified to suit changing operational needs. It also supports zone picking, which allows multiple workers to pick parts of the same order simultaneously—another big win for efficiency.

4. Ease of Use and Training

Training warehouse staff to use a pick to light system is quick and straightforward. The visual interface is intuitive, which means new employees can become productive with minimal onboarding time. This is particularly beneficial in industries with high employee turnover.

How StackIOT is Elevating Pick to Light Systems

As technology continues to evolve, advanced players like StackIOT are integrating smart IoT solutions into traditional pick to light systems. StackIOT’s approach enhances the system by offering:

- Real-time data analytics: Warehouse managers can monitor performance, identify bottlenecks, and make data-driven decisions to improve operations.

- Seamless ERP integration: StackIOT ensures smooth communication between warehouse systems and enterprise software, eliminating data silos and streamlining order processing.

- Remote monitoring and control: With IoT-enabled dashboards, managers can supervise operations from anywhere, ensuring uninterrupted productivity.

By combining IoT intelligence with traditional pick to light functionalities, StackIOT is setting new standards in warehouse automation.

Applications of Pick to Light Systems in Warehouses

A pick to light system in warehouse operations is especially effective in the following areas:

- E-commerce fulfillment centers: Where speed and accuracy are paramount.

- Pharmaceutical warehouses: Where precision is critical to ensure safety and compliance.

- Automotive parts distribution: Where managing thousands of SKUs requires streamlined picking.

- Retail and grocery warehouses: Where high turnover rates demand rapid replenishment and accuracy.

ROI and Cost Considerations

While the upfront cost of implementing a pick to light system may seem high compared to manual picking, the long-term return on investment is substantial. Companies typically see:

- Increased order accuracy

- Reduced labor costs

- Faster order turnaround

- Higher customer satisfaction

When paired with a platform like StackIOT, which offers enhanced analytics and real-time insights, the ROI improves even further by enabling continuous process optimization.

Challenges and Considerations

Though highly effective, pick to light systems are best suited for fast-moving inventory and may not be ideal for all warehouse types—especially those with large or slow-moving SKUs. It's also crucial to ensure proper system integration and employee training to realize the full benefits.

Conclusion

The Pick to Light System is undoubtedly a game-changer in the world of inventory and warehouse management. As businesses continue to pursue greater efficiency, fewer errors, and better customer satisfaction, adopting intelligent solutions like pick to light system in warehouse operations becomes essential.

Innovators like StackIOT are leading the charge by enhancing traditional systems with IoT capabilities, offering warehouses a smarter, more connected way to manage their operations. Whether you're scaling up an e-commerce business or refining logistics for an enterprise, a Pick to Light System could be the missing link in achieving operational excellence.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.