Role of Manufacturing Efficiency in Reducing SS 304 Pipe Prices Per Kg

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

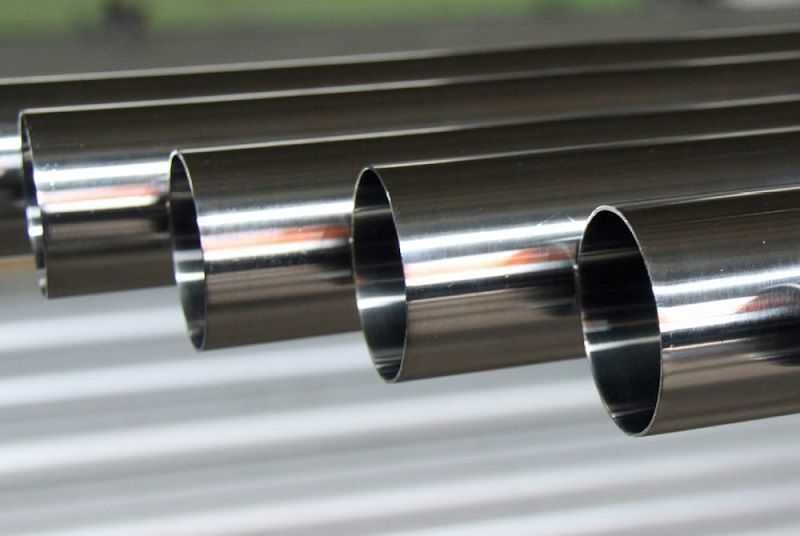

In the competitive world of stainless steel, efficiency in manufacturing processes is crucial for controlling costs and delivering value to customers. One significant factor in determining the SS 304 pipe price per kg is how efficiently a manufacturer operates. This article explores how manufacturing efficiency impacts SS 304 pipe prices per kg and examines its role in the broader context of the Stainless Steel Pipe Price List.

Understanding Manufacturing Efficiency

Manufacturing efficiency refers to the ability of a production facility to produce high-quality products at the lowest possible cost. It involves optimizing various aspects of the manufacturing process, including:

Raw Material Utilization: Efficient use of raw materials reduces waste and lowers production costs. Improved techniques for utilizing stainless steel scrap and minimizing losses during production can significantly impact the final SS 304 pipe price per kg.

Production Technology: Modern and advanced machinery can enhance precision, speed up production, and reduce errors. The use of automated systems and cutting-edge technology leads to higher efficiency and lower costs per unit.

Energy Consumption: Reducing energy consumption is a key factor in manufacturing efficiency. Energy-efficient processes and equipment contribute to lower production costs, which can be reflected in the Stainless Steel Pipe Price List.

Labor Productivity: Skilled labor and efficient workforce management can improve productivity. Training employees, optimizing workflow, and employing best practices enhance overall efficiency and help in maintaining competitive SS 304 pipe prices per kg.

Impact on SS 304 Pipe Prices Per Kg

Cost Reduction

Manufacturing efficiency directly affects the cost structure of producing stainless steel pipes. When a manufacturer improves their efficiency, they can reduce production costs in several ways:

Lower Operational Costs: Efficient processes require less time and labor, leading to lower operational expenses. These savings can be passed on to customers, resulting in a reduced SS 304 pipe price per kg.

Reduced Waste: Efficient use of materials minimizes waste and scrap, lowering the cost of raw materials and contributing to a more competitive Stainless Steel Pipe Price List.

Economies of Scale: Improved efficiency often allows manufacturers to scale up production. Higher production volumes can lead to economies of scale, reducing the cost per unit and making SS 304 pipe prices per kg more affordable.

Quality Improvement

Efficiency also enhances product quality, which can affect pricing indirectly. High-quality pipes with fewer defects and better performance are valued by customers and can justify a competitive price. Efficient manufacturing processes ensure that products meet stringent quality standards, which can influence the overall Stainless Steel Pipe Price List.

Market Competitiveness

Manufacturers that excel in efficiency can offer more competitive pricing. By lowering their SS 304 pipe price per kg, they can attract more customers and gain a competitive edge in the market. This ability to offer competitive prices while maintaining high quality is a significant advantage in the stainless steel industry.

Example of How Efficiency Affects Pricing

Consider a manufacturer that adopts advanced production techniques and improves material utilization. This manufacturer can achieve a lower SS 304 pipe price per kg compared to competitors who have less efficient processes. The improved efficiency might result in a price reduction from $3.00 per kg to $2.50 per kg, making their products more attractive in the market.

Stainless Steel Pipe Price List

An example Stainless Steel Pipe Price List reflecting the impact of manufacturing efficiency might look like this:

Grade Type Size Range (inches) Price per Kg Notes

SS 304 Seamless 1/8" - 24" $2.50 Efficient production

SS 304 Welded 1/8" - 48" $2.00 Reduced waste, lower cost

SS 316 Seamless 1/8" - 24" $3.00 Higher grade, higher cost

SS 316 Welded 1/8" - 48" $2.50 Economies of scale

Note: Prices are indicative and subject to change based on manufacturing efficiency and market conditions.

Conclusion

Manufacturing efficiency plays a pivotal role in determining the SS 304 pipe price per kg. By optimizing raw material utilization, embracing advanced technology, reducing energy consumption, and improving labor productivity, manufacturers can lower production costs and offer more competitive prices. This efficiency not only affects the Stainless Steel Pipe Price List but also enhances product quality and market competitiveness.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.