Automated Blog-to-Social Sharing – Publish Once. Appear Everywhere!

Automated Blog-to-Social Sharing – Publish Once. Appear Everywhere!

Russia CNC Drilling Machine Market: Mollart Engineering’s Influence and Strategic Innovations

Written by ratan deb » Updated on: June 17th, 2025

Introduction:

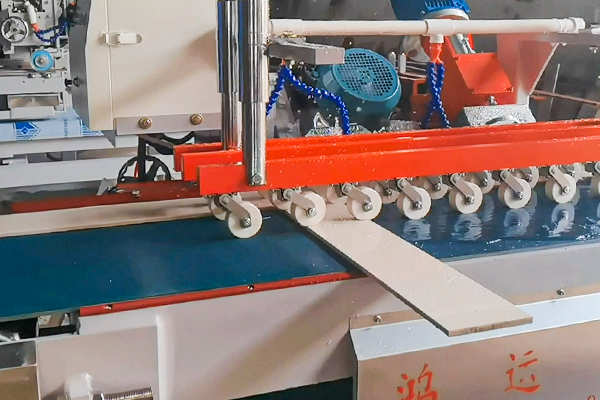

The Russia CNC Drilling Machine Market is experiencing significant growth, driven by the increasing adoption of advanced machining technologies in key industries such as aerospace, automotive, construction, and manufacturing. Within this dynamic landscape, Mollart Engineering, a leading global provider of deep hole drilling solutions, has emerged as a key player shaping the market’s trajectory. This article explores Mollart Engineering’s influence on Russia’s CNC drilling machine market, along with the strategies, emerging innovations, and developments adopted by the industry.

Mollart Engineering’s Role in Russia’s CNC Drilling Market

Mollart Engineering is renowned for its expertise in deep hole drilling, gun drilling, and precision engineering. The company has significantly contributed to advancing CNC drilling technology in Russia through its high-precision solutions and innovative manufacturing processes. Key aspects of its influence include:

1. Advanced Deep Hole Drilling Solutions

Mollart Engineering’s cutting-edge deep hole drilling machines have become indispensable in Russia’s heavy industries. Their multi-axis CNC drilling machines offer enhanced accuracy, repeatability, and efficiency, meeting the demands of industries such as oil and gas, aerospace, and defense.

2. Customization and Tailored Solutions

Recognizing the diverse needs of Russian manufacturers, Mollart Engineering offers customizable CNC drilling solutions tailored to specific industry requirements. This flexibility has strengthened its position in the market, attracting partnerships with leading manufacturing firms.

3. Training and Knowledge Transfer

To address the skills gap in the Russian CNC industry, Mollart Engineering actively collaborates with local technical institutions and companies. The firm provides training programs, technical workshops, and hands-on demonstrations, equipping operators with the expertise needed to handle advanced drilling machinery.

Strategies Driving Russia’s CNC Drilling Machine Market

To stay ahead in the global manufacturing landscape, the Russian CNC drilling machine market has embraced several strategic initiatives:

1. Focus on Technological Advancements

The market is seeing a shift towards automation, AI-driven CNC machines, and IoT-enabled manufacturing processes. Mollart Engineering has been at the forefront of these innovations, integrating smart controls and data analytics into its machines to enhance productivity and minimize downtime.

2. Strengthening Domestic Manufacturing

In response to economic sanctions and import restrictions, Russia is increasingly investing in domestic production of CNC drilling machines. Local companies are collaborating with global players like Mollart Engineering to develop high-quality, homegrown solutions.

3. Sustainability and Energy Efficiency

Environmental concerns and energy efficiency are gaining prominence in Russia’s manufacturing sector. Mollart Engineering has adapted by introducing eco-friendly CNC drilling technologies that reduce waste and energy consumption, aligning with Russia’s industrial sustainability goals.

Emerging Innovations and Developments in Russia’s CNC Drilling Market

The Russian CNC drilling industry is undergoing transformative changes, with a strong emphasis on innovation. Key developments include:

1. AI-Powered CNC Drilling Machines

The integration of artificial intelligence into CNC drilling machines is revolutionizing machining accuracy and predictive maintenance. Mollart Engineering has pioneered AI-driven solutions that optimize drilling processes, enhancing precision and reducing material waste.

2. Multi-Axis and Hybrid CNC Machines

With increasing demand for complex and high-precision drilling, multi-axis CNC machines are becoming the norm. Mollart Engineering’s hybrid solutions, which combine drilling, milling, and threading in a single machine, are gaining traction among Russian manufacturers seeking versatile and efficient equipment.

3. Expansion of Automated Production Lines

Automation is transforming Russian manufacturing facilities, leading to increased adoption of robotic-assisted CNC drilling machines. Mollart Engineering has responded by integrating robotic arms and automated tool changers into its CNC systems, significantly improving operational efficiency.

Conclusion

Mollart Engineering continues to play a pivotal role in shaping Russia’s CNC drilling machine market through its technological expertise, training initiatives, and commitment to innovation. As the market evolves, strategies such as automation, AI integration, and domestic production will define its future growth. By embracing these advancements and partnering with industry leaders like Mollart Engineering, Russia’s CNC drilling sector is poised for sustained success in the global manufacturing landscape.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.