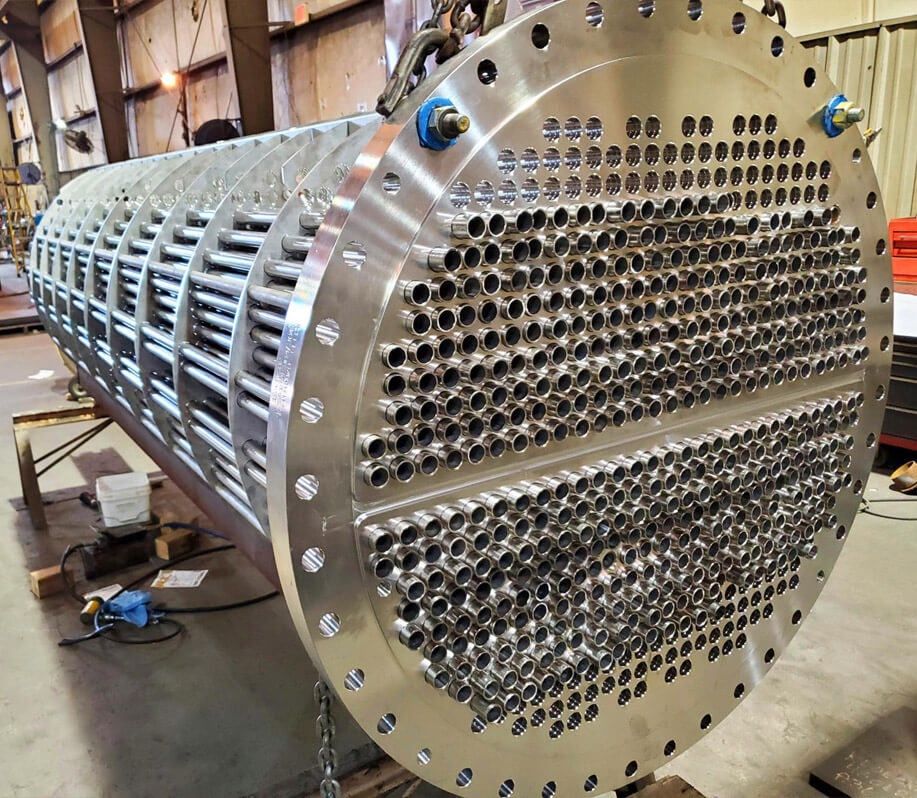

Stainless Steel 317L Welded U Tubes: High-Performance Tubing for Corrosive Environments

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Stainless Steel 317L Welded U Tubes are widely recognized for their exceptional performance in highly corrosive and high-temperature environments. Designed specifically for heat exchanger systems, condensers, and boiler applications, these tubes are fabricated using a low carbon version of SS 317, offering superior corrosion resistance, especially against sulfurous and acidic media.

In this article, we will explore the properties, benefits, applications, and technical advantages of 317L welded U tubes, along with why they are a preferred choice in industries demanding long-term reliability.

What is Stainless Steel 317L?

Stainless Steel 317L is an austenitic chromium-nickel stainless steel alloy with increased molybdenum content. The “L” denotes its low carbon composition, which enhances its resistance to sensitization during welding and exposure to high temperatures. This makes 317L highly suitable for welded applications and environments involving aggressive chemicals such as chlorides, sulfur compounds, and acetic acids.

Chemical Composition (%):

Chromium (Cr): 18 – 20

Nickel (Ni): 11 – 15

Molybdenum (Mo): 3 – 4

Carbon (C): ≤ 0.03

Manganese (Mn), Silicon (Si), Phosphorus (P), Sulfur (S): Trace amounts

Key Features of SS 317L Welded U Tubes

✅ Superior Corrosion Resistance: Performs well in acidic and chloride-rich environments, especially in reducing conditions.

✅ Excellent Weldability: Low carbon content reduces carbide precipitation during welding, ensuring enhanced intergranular corrosion resistance.

✅ High Temperature Strength: Withstands elevated temperatures and high-pressure applications without compromising mechanical integrity.

✅ Custom U-Bend Design: The U shape provides efficient thermal exchange, making them perfect for compact heat exchanger designs.

Manufacturing and Quality Standards

Stainless Steel 317L Welded U Tubes are manufactured by rolling and welding high-quality SS 317L strips, followed by precision U-bending and heat treatment to relieve stress. Common standards include:

ASTM A249 / A688 / A269

ASME SA249 / SA269

NACE MR0175

ISO, EN, DIN equivalents upon request

Tubes are typically subjected to non-destructive testing (hydrostatic, eddy current, PMI) to ensure flawless performance in critical applications.

Applications of 317L Welded U Tubes

These welded U tubes are extensively used in industries where high corrosion resistance and temperature stability are crucial:

🏭 Chemical and Petrochemical Plants

⚗️ Acid Processing Equipment

🌡️ Heat Exchangers and Condensers

🔄 Power Generation Units

🛢️ Oil & Gas Refineries

🧪 Pulp and Paper Industry

🌍 Marine and Desalination Projects

The U-shaped bend enables better heat transfer efficiency while saving space, making them ideal for applications with compact design requirements.

Advantages Over Conventional Grades

Feature SS 304/316 SS 317L

Corrosion Resistance Moderate Excellent

Molybdenum Content 2–2.5% (316) 3–4%

Heat Resistance Good Higher

Sensitization Risk Medium Low

Cost Lower Slightly higher, justified by performance

Why Choose SS 317L Welded U Tubes from a Trusted Exporter?

When sourcing 317L welded U tubes, selecting a reputable manufacturer and exporter is crucial. Leading suppliers like Metinox Overseas ensure:

✅ Stringent quality control and dimensional accuracy

✅ Timely delivery across global markets

✅ Full material traceability with MTCs

✅ Customized lengths, diameters, and U-bends as per client specifications

Conclusion

Stainless Steel 317L Welded U Tubes offer unmatched resistance to aggressive chemical environments, high thermal strength, and excellent weldability, making them indispensable for modern industrial systems. Their use not only extends the life of critical equipment but also improves thermal efficiency, minimizes maintenance, and ensures compliance with international standards.

If you are looking for high-quality SS 317L welded U tubes for your heat exchanger or processing application, consider working with an experienced and certified supplier to ensure reliability and performance.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.