Top Benefits of Choosing Stainless Steel 304 Coil Tubing

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Stainless Steel 304 Coil Tubing is widely regarded as one of the most versatile and commonly used stainless steel tubing solutions across a range of industries. Thanks to its excellent corrosion resistance, formability, and mechanical properties, SS 304 Coil Tubing offers a cost-effective and durable option for fluid and gas transmission in both industrial and commercial applications. This article explores the properties, benefits, applications, and specifications of Stainless Steel 304 Coil Tubing to help understand why it remains a popular choice globally.

What is Stainless Steel 304 Coil Tubing?

Stainless Steel 304 Coil Tubing is made from grade 304 stainless steel, a member of the austenitic family, and is manufactured in coiled form rather than straight lengths. Coil tubing is typically used in long continuous runs, minimizing the need for multiple fittings or welds. The continuous coil structure not only reduces the risk of leakage but also lowers installation time and cost.

Grade 304 is composed of 18% chromium and 8% nickel, which gives it excellent resistance to oxidation, chemicals, and atmospheric corrosion. It's non-magnetic in the annealed condition and can be cold-worked to increase its strength.

Key Features and Properties

Corrosion Resistance

SS 304 offers excellent corrosion resistance in a wide range of environments, including acidic and mildly corrosive conditions. It resists rust and chemical damage, making it suitable for chemical, marine, and food processing environments.

High Strength and Durability

Despite its excellent corrosion resistance, 304 stainless steel does not compromise on strength. Coil tubing made from SS 304 offers good mechanical strength and long service life, even under high-pressure and high-temperature conditions.

Excellent Weldability and Formability

304 stainless steel is highly formable and weldable, making it ideal for coiling and reshaping into compact tube configurations. It can be easily welded using standard welding techniques without compromising its structural integrity.

Smooth Inner Surface

The inner surface of SS 304 coil tubing is typically smooth, reducing friction and pressure drop during fluid transmission. This smooth finish also resists scaling and contamination.

Temperature Tolerance

SS 304 can withstand temperatures up to 870°C (1600°F) in continuous service and up to 925°C (1700°F) in intermittent service, making it ideal for heat transfer and thermal applications.

Specifications and Standards

SS 304 Coil Tubing is manufactured according to international standards to ensure quality and consistency. Common standards include:

ASTM A269 / A213 / A249

EN 10216-5

ASME SA213 / SA269

Common Sizes

Outer Diameter: 1/8" to 1" (3.18mm to 25.4mm)

Wall Thickness: 0.028" to 0.083" (0.7mm to 2.1mm)

Coil Lengths: Up to several hundred feet per coil

Sizes can be customized based on project requirements, with seamless or welded options available.

Applications of Stainless Steel 304 Coil Tubing

The durability and versatility of SS 304 Coil Tubing make it useful in a wide range of industries:

Oil and Gas Industry

Used in hydraulic control lines, chemical injection systems, and subsea umbilicals due to its ability to withstand harsh environments and high pressures.

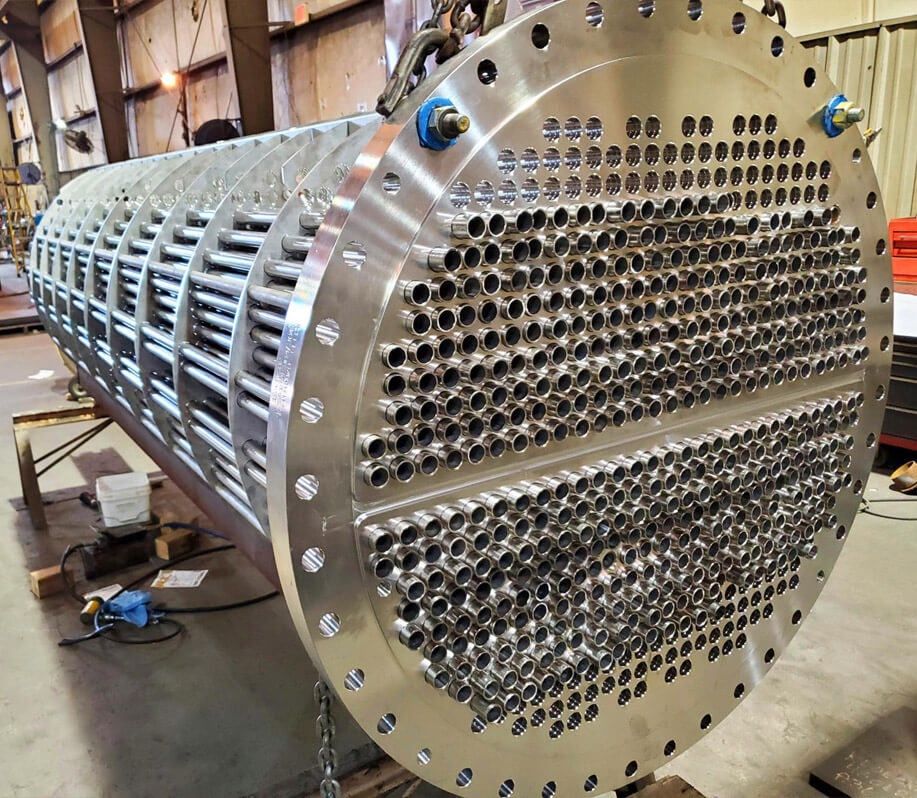

Heat Exchangers and Condensers

SS 304 Coil Tubing is ideal for use in heat exchanger systems due to its thermal conductivity and corrosion resistance.

Food and Beverage Processing

The hygienic properties of SS 304 make it ideal for transporting food-grade liquids, milk, beverages, and cleaning agents.

Chemical and Pharmaceutical Industries

Resistant to a wide range of chemicals, 304 coil tubing is used in instrumentation, fluid delivery, and process systems in clean environments.

Automotive and Aerospace

Lightweight and corrosion-resistant tubing is essential for fluid transfer systems in vehicles and aircraft.

HVAC and Refrigeration

Used in cooling and heating systems for its thermal performance and resistance to scaling and fouling.

Advantages of Using SS 304 Coil Tubing

Leak-Free Design: Fewer fittings and joints mean fewer chances of leaks and system failures.

Reduced Installation Costs: Continuous coils are easier and faster to install.

Longevity: The natural corrosion resistance of stainless steel ensures a long service life with minimal maintenance.

Versatility: Suitable for both indoor and outdoor environments, including marine and chemical exposure.

Environmentally Friendly: Stainless steel is 100% recyclable, making it a sustainable material choice.

Conclusion

Stainless Steel 304 Coil Tubing is a robust, reliable, and cost-efficient solution for fluid and gas transport across diverse industries. Its corrosion resistance, formability, and strength make it a top choice for engineers and manufacturers looking for long-lasting performance. Whether for heat exchangers, instrumentation, or fluid systems, SS 304 Coil Tubing offers a balance of performance, value, and safety that few materials can match.

For high-quality Stainless Steel 304 Coil Tubing that meets global standards, always source from reputable manufacturers and suppliers to ensure performance and durability.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.