Corrosion-Resistant Instrumentation Tubes: Why SS 317/317L Leads the Industry

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

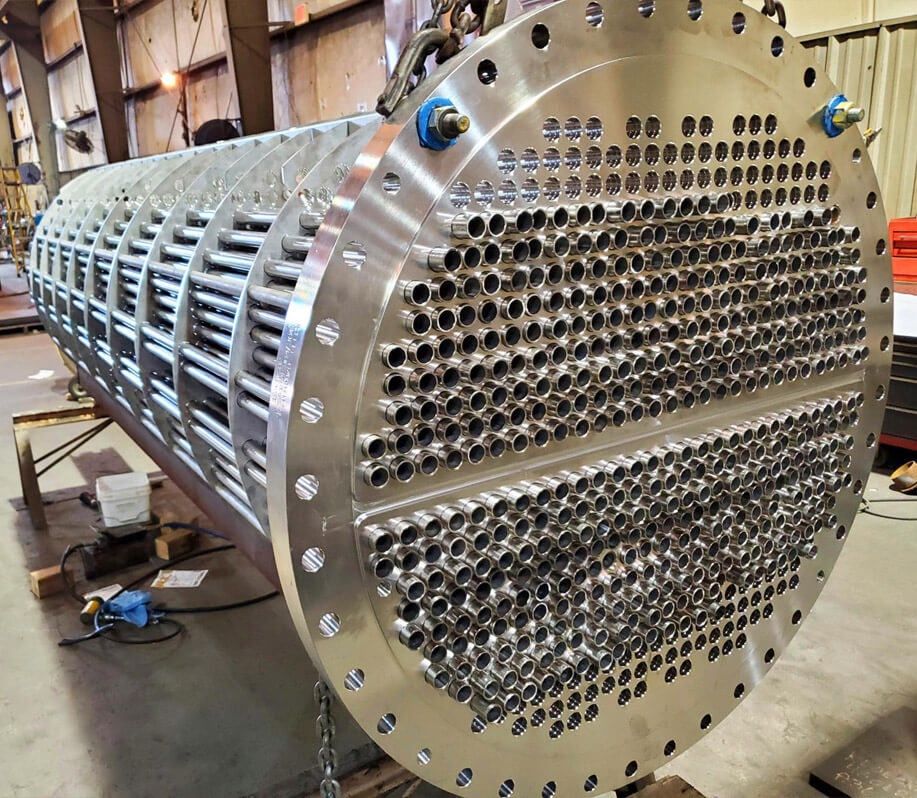

Stainless Steel 317 and 317L Instrumentation Tubes are high-performance austenitic stainless steel tubing products engineered for demanding applications where enhanced corrosion resistance and mechanical integrity are essential. These grades, known for their high molybdenum content and low carbon composition, offer exceptional strength, superior resistance to pitting, and excellent fabrication characteristics. They are widely used in industries such as petrochemical, power generation, marine, and pharmaceuticals, especially in instrumentation and control systems.

Understanding Stainless Steel 317 and 317L

Stainless Steel 317 (UNS S31700) is an austenitic stainless steel alloy that contains higher levels of molybdenum (3.0-4.0%) compared to standard 316 grade. This addition improves resistance to chemical attack from chlorides, sulfates, and other harsh substances.

Stainless Steel 317L (UNS S31703) is the low-carbon version of 317, which enhances its weldability and minimizes carbide precipitation during welding, making it suitable for applications where heavy gauge welding is required and post-weld annealing is not feasible.

Key Features of SS 317/317L Instrumentation Tubes

1. High Corrosion Resistance:

o Enhanced resistance to pitting and crevice corrosion in chloride environments.

o Excellent performance in acidic media like sulfuric and phosphoric acid.

2. Superior Weldability and Formability:

o 317L’s low carbon content minimizes the risk of intergranular corrosion post-welding.

o Excellent machinability and fabrication capabilities allow for complex system integration.

3. High Strength and Durability:

o Better creep and tensile strength at elevated temperatures compared to conventional stainless steels.

o Long service life in aggressive environments reduces replacement frequency and costs.

4. Dimensional Accuracy:

o Tight tolerances make these tubes ideal for precision control systems and instrumentation setups.

5. Clean Surface Finish:

o Available in polished or bright annealed finishes, ensuring low contamination risk in sensitive systems.

Applications of SS 317/317L Instrumentation Tubes

Due to their outstanding corrosion resistance and mechanical properties, these instrumentation tubes are used in:

• Chemical and Petrochemical Plants: For transmitting corrosive fluids under controlled pressure and temperature.

• Oil and Gas Industry: In offshore platforms and refineries for process control systems.

• Power Generation: Including nuclear and thermal power stations, where tubes must withstand high temperatures and aggressive conditions.

• Pharmaceutical and Food Processing: Suitable for hygienic environments due to smooth internal surfaces and ease of cleaning.

• Pulp and Paper Industry: Resistance to acidic bleaching agents makes 317/317L ideal in this sector.

Specifications and Standards

SS 317/317L Instrumentation Tubes conform to international standards such as:

• ASTM A213 / A269 / A312

• ASME SA213 / SA269 / SA312

• DIN, EN, and ISO standards based on customer requirements

Available Forms:

• Seamless and Welded Tubes

• Straight Lengths and Coil Form

• Sizes: 1/8" to 2" OD (custom sizes on request)

• Wall Thickness: As per requirement (SWG/BWG)

Why Choose SS 317/317L for Instrumentation?

When precision, reliability, and corrosion resistance are non-negotiable, SS 317/317L Instrumentation Tubes are a top choice. Their ability to withstand aggressive environments while maintaining high structural integrity makes them indispensable in mission-critical applications.

Conclusion

Stainless Steel 317/317L Instrumentation Tubes offer a perfect blend of strength, corrosion resistance, and workability. Whether you're dealing with harsh chemical environments or high-temperature systems, these tubes deliver consistent performance and reliability. For engineers and project managers seeking optimal solutions for instrumentation and control systems, SS 317/317L remains a preferred material of construction.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.