Why Stainless Steel 310/310S Tubes Are Ideal for High-Heat Instrumentation Applications

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

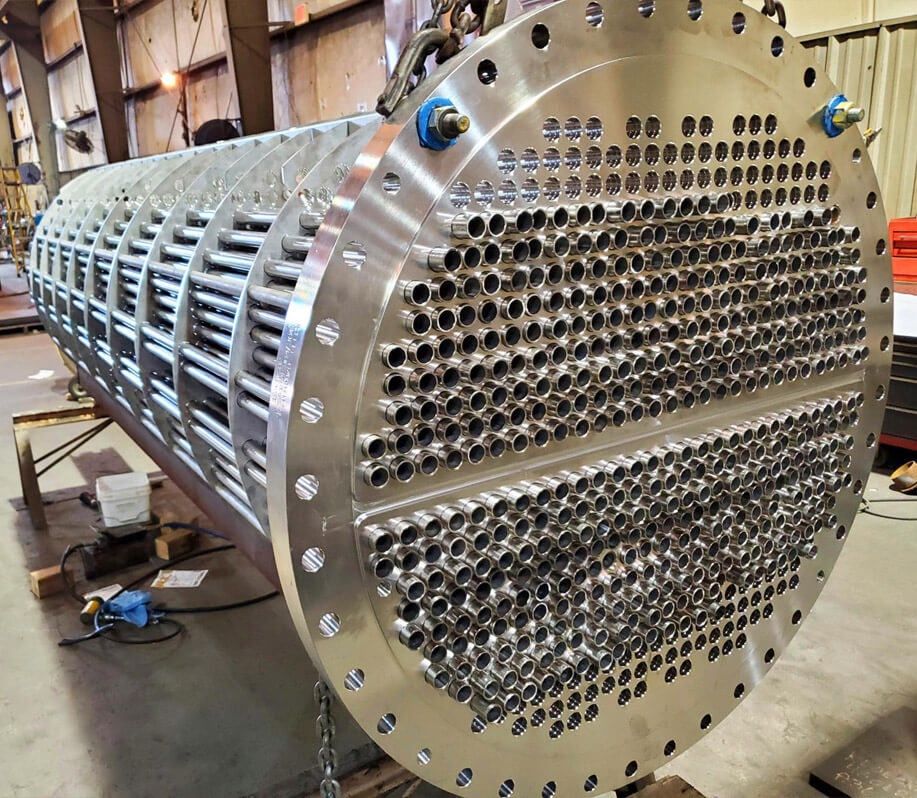

Stainless Steel 310 and 310S Instrumentation Tubes are engineered to perform under the harshest industrial conditions. These high-alloy austenitic stainless steels are known for their exceptional resistance to high-temperature oxidation, scaling, and corrosion. Ideal for applications involving heat and pressure, 310/310S instrumentation tubes are the backbone of instrumentation systems in power plants, chemical industries, oil & gas refineries, and thermal processing units.

In this article, we explore the key features, advantages, and applications of Stainless Steel 310/310S Instrumentation Tubes that make them indispensable for high-performance environments.

________________________________________

What Are Stainless Steel 310 and 310S?

Stainless Steel 310 is a high-temperature, chromium-nickel alloy containing 25% chromium and 20% nickel. This composition delivers superior resistance to oxidation and heat scaling. Stainless Steel 310S is the low-carbon version of 310, offering improved weldability and reduced risk of carbide precipitation during welding or prolonged exposure to high temperatures.

Key Composition:

• Chromium: ~24-26%

• Nickel: ~19-22%

• Carbon:

o 310: ≤ 0.25%

o 310S: ≤ 0.08%

________________________________________

Key Features of SS 310/310S Instrumentation Tubes

1. Exceptional High-Temperature Resistance

Can withstand continuous service at temperatures up to 1100°C (2012°F) and intermittent exposure up to 1150°C (2102°F), making them ideal for extreme thermal environments.

2. Outstanding Oxidation and Scaling Resistance

Protects the integrity of the tube under oxidative conditions, even in aggressive atmospheres.

3. Superior Corrosion Resistance

Performs well in both acidic and neutral environments, and highly resistant to sulfidation and carburization.

4. High Strength and Structural Stability

Retains mechanical strength and dimensional stability under both static and dynamic stress.

5. Excellent Weldability and Fabrication

310S offers better weldability and is often preferred where extensive fabrication or welding is required.

6. Tight Dimensional Tolerances

Ensures consistent performance in precision instruments and control systems.

________________________________________

Applications of Stainless Steel 310/310S Instrumentation Tubes

310/310S instrumentation tubes are widely used across industries where heat, pressure, and corrosion are major concerns:

• Petrochemical & Chemical Processing

Instrument lines for control systems in furnaces, reformers, and reactors.

• Power Generation

Used in superheaters, reheaters, and high-temperature instrumentation circuits.

• Oil & Gas Industry

Suitable for high-pressure gas and liquid control lines exposed to sour gas or high-temperature zones.

• Thermal Processing Units

Perfect for instruments that operate in kilns, annealing chambers, or heat treatment systems.

• Aerospace & Marine Applications

Ideal for systems exposed to extreme temperatures and corrosive atmospheres.

________________________________________

Advantages Over Standard Stainless Steels

• Higher temperature tolerance than 304/304L and 316/316L

• Superior scaling resistance at elevated temperatures

• Longer service life under thermal cycling and corrosive conditions

• Available in seamless & welded forms with precise OD and wall thickness

________________________________________

Standards and Specifications

• ASTM: A213 / A269 / A632

• ASME: SA213 / SA269

• OD Range: 1/8" to 2"

• Wall Thickness: 0.5 mm to 3.0 mm

• Delivery Condition: Bright annealed, pickled, or polished

________________________________________

Conclusion

Stainless Steel 310/310S Instrumentation Tubes are the top choice for engineers and project designers seeking unmatched performance in extreme environments. Whether in furnace systems, refineries, or thermal plants, these tubes ensure long-term reliability, accuracy, and safety in instrumentation systems.

Choosing high-quality 310/310S instrumentation tubes from trusted suppliers guarantees optimal performance, compliance with international standards, and extended operational life even under the most demanding conditions.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.