Stainless Steel 316Ti Welded Tubes: Durability, Performance, and Long-Term Value

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Stainless Steel 316Ti welded tubes have become a preferred choice across many industries due to their enhanced mechanical properties and excellent corrosion resistance. These tubes are a titanium-stabilized version of the 316 grade, designed to offer superior performance in high-temperature environments. If you're looking for high-strength welded tubes with exceptional longevity and corrosion resistance, Stainless Steel 316Ti is a reliable and efficient solution.

In this article, we’ll explore the benefits, applications, and specifications of Stainless Steel 316Ti welded tubes to help you understand why they are widely used in various industrial sectors.

What is Stainless Steel 316Ti?

Stainless Steel 316Ti is a titanium-stabilized austenitic stainless steel that contains molybdenum, providing excellent resistance to pitting and crevice corrosion. The titanium content in 316Ti is typically around 0.5%, which helps prevent carbide precipitation during welding or high-temperature service. This feature ensures better structural integrity and corrosion resistance, particularly in high-heat environments.

316Ti is similar in chemistry to 316L but has the added benefit of titanium stabilization, making it ideal for applications where long-term exposure to elevated temperatures is required.

Key Features of 316Ti Welded Tubes

1. High Corrosion Resistance

316Ti welded tubes exhibit excellent resistance to a wide range of corrosive environments. Thanks to the molybdenum content, these tubes are highly resistant to chloride ion attacks, making them suitable for marine, chemical, and offshore environments.

2. Superior Heat Resistance

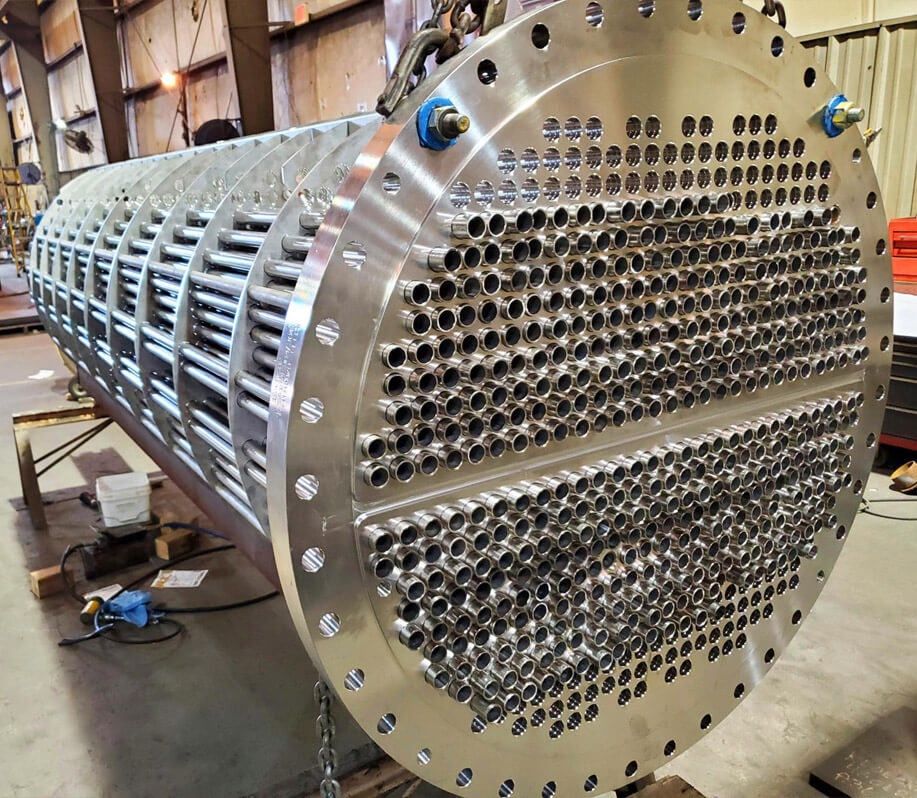

One of the main advantages of 316Ti over 316L is its improved performance at high temperatures. The titanium content helps maintain the steel’s strength and corrosion resistance even when exposed to temperatures up to 870°C (1600°F). This makes the tubes ideal for heat exchanger systems and exhaust lines.

3. Excellent Weldability and Formability

316Ti welded tubes are manufactured through advanced welding techniques that ensure a smooth surface finish, uniform wall thickness, and tight dimensional tolerance. The material’s excellent weldability and ductility allow it to be easily fabricated into various shapes and sizes to meet specific industrial requirements.

4. Long Service Life

Due to its outstanding mechanical properties and resistance to oxidation and scaling, 316Ti welded tubing ensures durability and long-term performance with minimal maintenance. This lowers the total cost of ownership over the product’s lifetime.

Applications of Stainless Steel 316Ti Welded Tubes

316Ti welded tubes are suitable for a variety of high-demand industries, including:

Chemical Processing Plants: With excellent resistance to acids and chlorides, these tubes are widely used in chemical tanks, pipelines, and reactors.

Power Generation: Ideal for heat exchangers and boilers that operate under high pressure and temperature.

Pharmaceutical and Food Processing: The smooth interior finish and resistance to contamination make 316Ti tubes perfect for hygienic applications.

Marine and Offshore: Due to their high resistance to pitting and corrosion in saltwater, these tubes are used in shipbuilding and offshore rigs.

Automotive and Aerospace: 316Ti welded tubes can withstand extreme conditions and are used in exhaust systems, hydraulic lines, and aircraft components.

Specifications and Standards

316Ti welded tubes are available in various sizes, thicknesses, and lengths, depending on your project needs. Common standards for these tubes include:

ASTM A249 / A269 / A312

DIN 1.4571

UNS S31635

They can be delivered in annealed, pickled, and polished conditions, depending on the application requirements.

Why Choose Stainless Steel 316Ti Welded Tubes from a Trusted Supplier?

When sourcing 316Ti welded tubes, it is essential to choose a reliable manufacturer or supplier who ensures high-quality production, rigorous testing, and timely delivery. Reputable suppliers adhere to international standards and offer full traceability with mill test certificates, ensuring you get the right material for your application.

Look for features like:

ISO-certified production

Non-destructive testing (NDT)

Third-party inspection (TPI)

Custom sizes and lengths

Conclusion

Stainless Steel 316Ti welded tubes offer an outstanding combination of corrosion resistance, strength, and heat stability, making them a preferred choice across multiple industries. Whether you're in the chemical, marine, power, or pharmaceutical sector, these tubes provide the long-term reliability and performance your systems require.

By investing in high-quality 316Ti welded tubes, you can ensure durability, reduce maintenance costs, and improve overall operational efficiency.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.