The ABS Pump: Key to Safe and Controlled Braking

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

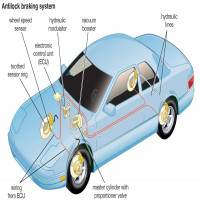

In the world of automotive safety, one system is almost as old as the cars themselves – the anti-lock braking system, or ABS. This incredibly important technology helps drivers of most modern automobiles to stop safely even under difficult driving conditions, such as driving in the rain, on ice, or on loose gravel. At the heart of the system is an ABS pump, a key component of the overall brake modulation and performance system. In the discussion below, we will look at what it is, how it works, why it is important, and its most common failure symptoms.

What is an ABS Pump?

The ABS pump, short for the anti-lock braking system, is a part of the hydraulic brake system that works in cooperation with wheel sensors and the ABS module or controller to regulate the hydraulic brake fluid pressure in the system to avoid brake lockup in emergency braking situations. This pump works to keep a constant pressure of the brake fluid flowing in the brake lines, so when the driver depresses the brake pedal, the brake linings grab the rotors of the wheels in emergencies, but the brakes don’t lock up, reducing the risk of skidding and loss of control.

The ABS pump operates by rapidly pulsing the brake pressure to the system when it detects that one of the wheels is about to lock up (that is, come to a complete stop) and then modulate the pressure to keep the car from skidding and increase maneuverability, even in hard braking.

How Does the ABS Pump Work?

And to help you follow how the ABS pump works, here’s how anti-lock braking works broken down into steps:

Sensing a Problem: The inputs are speed sensors built into each wheel that are monitoring their speed of rotation. These sensors see that one or more wheels are decelerating too quickly – an indicator that the wheel may lock up and fail to turn.

Signalling back once the ABS is in action: after the activation of the system, the control unit drive a signal to the ABS pump. If the pump control unit detects a malfunction, it will flash the vehicle brake lights Like a diaphragm, the drive moves up and down, simultaneously flowing and stopping the hydraulic fluid to the brakes, spinning the wheel but never allowing it to completely lock.

Pulsating pressure: Several times a second, the inlet pressure control valve in the ABS pump changes the brake pressure, resulting in pulsating pressure that the driver will feel at the brake pedal This pulsating action brings back traction and stops the wheels from locking.

Release and apply: The ABS pump alternates between releasing and applying brake pressure while the vehicle is decelerating until it’s travelling slow enough that wheel lock-up is no longer a risk. This is a very fast cycle, with interactions generally occurring in the milliseconds range, which is important when you need to activate it in a critical situation.

The Role of the ABS Pump in Vehicle Safety

If the ABS pump fails, emergency braking will be impaired – meaning you won’t be able to steer in such a situation. Older cars without ABS would lock up the brakes when hard braking was applied, which would make the vehicle spin out of control – especially when braking sliding on a wet road.

Finally, spinning the wheels in the opposite direction of the skid resulted from the installation not only of ABS, but also of the ABS pump, so that the wheels would turn a bit even at maximum braking, allowing the vehicle to be steered without skidding while stopped. An obstacle can thus be avoided, or a curve safely negotiated, when the car’s brakes are suddenly applied.

In conclusion it can be said when you consider the whole car, which the above context does, it can be said that above mentioned features reduce stopping distance at the time of an emergency, which enhances safety.Whereas the ABS pump enhances safety and performance by preventing skidding and reducing stopping distances under all driving conditions and road conditions.

Common ABS Pump Problems

With time, just as for any mechanical part, the ABS pump becomes worn out or defective, among other restrictions:

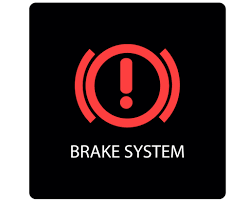

Pump Motor Failure: The motor inside the ABS pump can fail, which is likely to result in a complete failure of the ABS system. At this point, incidentally, the light will probably come on at the dashboard to tell you this.

Hydraulic Problems: The hydraulic brake fluid is managed by the ABS pump. The ABS pump will not function if there is a fluid leak in the system, or the fluid runs low.

Electrical Problems: The ABS pump is an ‘electronic’ piece of equipment that can be controlled by electrical signals. Faults in the electrical system, such as broken wires and a faulty ABS control module, can prevent the pump from working correctly.

Symptoms of a Failing ABS Pump

You need to check for the signs of a bad ABS pump, as it can cause some issues if it's not functioning correctly. The most common symptoms that may occur are:

ABS warning light: Want a first sign something’s wrong with the ABS pump? How about the dashboard warning light? ‘That light has illuminated,’ says Burkhalter, ‘indicating that there is an issue that the system has figured out and will no longer allow the pump to work.’

Pulsing Brake Pedal: Normally you’ll feel some pulsing in the brake pedal when ABS is activated, but pulsing in the pedal when you just hit the brakes – no ABS activated – means that you have a problem with either the pump or the system.

Longer Stopping Distance: If your vehicle is taking longer to stop – particularly during stopping incidents – you could have an ABS pump that isn’t working. This may mean that the brakes aren’t delivering enough pressure to give you the stopping power you require.

Strange noises The ABS warning light there’s a problem with the ABS pump. When a suspected bad pump is depressed and released, you’ll likely hear the noises again, but they’ll be different than before: grinding, humming, or hydraulic clicking sounds. The noises are likely a result of the pump struggling to modulate brake pressure.

How to Maintain Your ABS Pump

check the anti-lock brake system pump regularly. This will help you keep it fully functional. Follow these steps to check service and parts for the ant-lock brake system pump:

Regular checks of brake fluid (which the ABS pump needs for operation) should include top-ups of existing fluid when necessary, and replacement of old or contaminated fluid.

Be Aware of the ABS Warning Light: Never drive with the ABS warning light on: have a mechanic check your vehicle’s electronic controls as soon as possible to diagnose any problems before they become severe.

Regular check-ups: periodic check of the brakes and ABS system for replacement of vehicle parts.

Conclusion

The ABS pump is a crucial partner in braking safely and keep the vehicle controlled under emergency braking situation, it regulate brake pressure and help to prevent wheel lock-up, this is help increase the braking safety and performance of the vehicle, thus can make make the vehicle stop quicker and to steer under the critical time.

Frequent maintenance to the ABS system and ABS pump repair if it found broken or wrong operation is essential for safe driving, having understand about the ABS pump work, recognise the problems are crucial to help maintain the vehicle road safety.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.