The Benefits of Choosing an Indian LCD Display Supplier for Cost-Effective Solutions

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

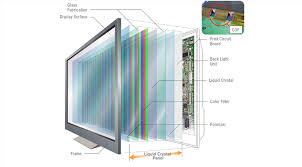

In today’s highly competitive electronics market, businesses around the world are continually seeking effective solutions for high-quality displays that don’t break the budget. India has emerged as a strong player in the electronics manufacturing sector, and choosing an LCD Display Supplier in India can bring a host of benefits, particularly for businesses looking to optimize costs without compromising on quality.

Indian manufacturers, such as Glomore—a leading LCD display manufacturer and supplier—are setting the bar high in this field, offering reliable, advanced, and cost-effective solutions that make partnering with Indian suppliers an attractive option for local and global companies.

1. Affordability Without Sacrificing Quality

India’s LCD display manufacturing sector has expanded rapidly, with competitive pricing structures that are particularly appealing for companies looking to manage expenses. Due to India’s favorable manufacturing conditions, including lower labor costs, efficient supply chains, and government initiatives like “Make in India,” local suppliers can offer high-quality displays at more affordable prices compared to counterparts in the U.S., Europe, or even China. According to industry data, manufacturing costs in India can be up to 20-30% lower than in other major electronics production countries, a savings that is passed on to clients.

A partnership with an Indian supplier such as Glomore enables businesses to invest in top-grade LCD displays while keeping expenses manageable. This cost advantage is especially critical in industries like consumer electronics and automotive, where tight profit margins make affordability a top priority.

2. Cutting-Edge Technology and Manufacturing Excellence

Indian LCD manufacturers are not only cost-competitive but are also known for their commitment to high-quality manufacturing processes and cutting-edge technology. In 2024, India has made considerable advancements in production technologies, with many suppliers implementing advanced production techniques such as automation, precision manufacturing, and extensive quality checks to meet global standards.

For example, Glomore utilizes advanced manufacturing facilities equipped with the latest technology to ensure that every display is crafted to precise specifications. This commitment to technology helps Indian suppliers compete on quality, delivering displays that meet the strict demands of industries such as medical equipment, telecommunications, and automotive.

3. A Strategic Focus on Customization

Customization is a key factor for businesses looking to stand out, and Indian LCD display suppliers are well-equipped to handle bespoke requirements. With a growing focus on Research and Development (R&D), companies like Glomore work closely with clients to design displays tailored to specific needs. Whether it’s customized screen dimensions, unique interface requirements, or specialized touch capabilities, Indian manufacturers provide flexible solutions.

According to recent surveys, about 70% of companies in the Indian display manufacturing sector reported that their clients requested some form of customization in 2023. This trend underscores the increasing value businesses place on having displays that are specifically designed for their applications. Partnering with an Indian supplier allows for streamlined customization, ensuring clients get products that are perfectly aligned with their brand and functionality requirements.

4. High Reliability and Quality Standards

In addition to affordability and customization, Indian manufacturers maintain high standards of quality and reliability. Indian companies are investing more in quality control, adhering to stringent testing procedures that ensure each product meets international standards. According to the Electronics and Computer Software Export Promotion Council (ESC), India’s focus on quality control in electronics has increased exports by 12% in 2023, reflecting the growing global trust in Indian-made products.

Glomore, for instance, implements rigorous testing processes, from initial raw materials to final product output, ensuring that displays perform consistently over their lifespan. The emphasis on quality assurance and reliability helps build a long-term partnership based on trust and performance, giving clients peace of mind that their products will function optimally in various applications.

5. Faster Turnaround Times for Production and Delivery

One of the biggest advantages of sourcing from an LCD Display Supplier in India is the speed at which Indian companies operate. With streamlined logistics networks and significant advancements in production efficiency, Indian suppliers can offer faster lead times. For businesses needing quick project turnaround, this responsiveness is invaluable, allowing them to meet tight deadlines and stay ahead in their markets.

Glomore, for example, has optimized its supply chain processes to minimize downtime and deliver orders promptly. The focus on speedy and reliable delivery is a significant advantage, especially for clients in industries with fluctuating demand cycles, such as consumer electronics.

6. Government Support and Industry Growth Initiatives

India’s government has introduced policies aimed at fostering the country’s electronics manufacturing sector, which has accelerated the growth of LCD display manufacturing. Initiatives like Production-Linked Incentives (PLI) provide financial incentives to local manufacturers, promoting higher output and encouraging global businesses to source from Indian suppliers. The PLI scheme alone has allocated over ₹40,000 crores ($5.4 billion USD) to support electronics manufacturing as of early 2024, a figure that underscores the government’s commitment to this sector.

The result? An ecosystem that is favorable for both manufacturers and buyers, with competitive pricing and support for cutting-edge production. By partnering with an Indian LCD display supplier, businesses benefit from these supportive policies, which translate into a steady supply of quality products at highly competitive rates.

7. Environmentally Sustainable Manufacturing Practices

Sustainability is a growing priority for companies globally, and Indian LCD manufacturers are stepping up to the challenge by implementing eco-friendly production practices. By adopting energy-efficient manufacturing processes and sourcing recyclable materials, Indian suppliers are actively working to reduce their environmental impact. In fact, a report from India’s Ministry of Electronics and Information Technology (MeitY) indicates that 50% of Indian manufacturers in the electronics sector are committed to reducing carbon emissions by 30% by 2025.

Choosing an environmentally conscious supplier not only aligns with corporate social responsibility goals but also appeals to increasingly eco-conscious consumers. Glomore and similar companies in India have taken strides to ensure their processes are both cost-effective and sustainable, benefiting both the environment and their clients.

8. Skilled Workforce and Customer Support

India’s electronics manufacturing sector benefits greatly from a skilled and adaptable workforce. Indian engineers and technicians are known for their expertise and ability to work on complex requirements, which translates into a product that meets high international standards. Furthermore, with a large English-speaking population, Indian suppliers provide seamless communication, making collaboration easier and more effective.

Glomore prides itself on offering dedicated customer support to address client queries promptly and provide solutions tailored to specific needs. This commitment to client satisfaction ensures that businesses partnering with an Indian LCD display supplier enjoy a supportive, professional relationship that’s geared toward long-term success.

Conclusion

Partnering with an LCD Display Supplier in India, such as Glomore, offers a clear edge for businesses aiming to reduce costs while maintaining quality. Indian suppliers combine affordable pricing, advanced technology, customization capabilities, high reliability, and strong government support to deliver displays that meet global standards.

As India continues to establish itself as a global electronics manufacturing hub, sourcing LCD displays from Indian suppliers not only helps companies cut costs but also contributes to a more sustainable and efficient supply chain. Choosing an Indian supplier is not merely a budget-friendly choice—it’s a strategic investment in quality, efficiency, and innovation for businesses striving to stay competitive in the modern electronics market.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.