Google Ads Done Right – More Clicks, Less Waste!

Google Ads Done Right – More Clicks, Less Waste!

The Role of a Plastic Molding Company in Streamlining Your Production Process

Written by Nubs Plastics Inc. » Updated on: June 17th, 2025

In today’s competitive manufacturing landscape, businesses seek efficient, high-quality, and cost-effective solutions to maintain a competitive edge. A plastic molding company plays a pivotal role in helping businesses streamline their production processes by offering precision, scalability, and innovative manufacturing solutions. From initial product design to final production, these companies leverage advanced technology and expertise to deliver durable and consistent plastic components.

Whether you are in the automotive, medical, electronics, or consumer goods industry, partnering with a plastic molding company can significantly improve operational efficiency. This article explores how plastic molding companies contribute to optimized production, cost savings, and overall business growth.

1. Precision and Consistency in Production

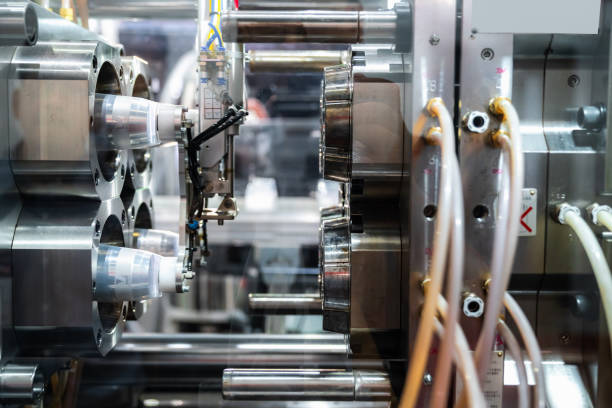

One of the biggest advantages of working with a plastic molding company is the ability to produce highly precise and consistent parts. With modern injection molding techniques, manufacturers can achieve tight tolerances, ensuring uniformity across all products.

- Automated Injection Molding Machines: These machines precisely control factors such as temperature, pressure, and injection speed, leading to minimal defects.

- High-Quality Molds: Custom molds ensure each part meets exact specifications, reducing the need for adjustments or rework.

- Repeatability: Once a mold is created, it can be used repeatedly to produce identical components, which is crucial for large-scale production.

By eliminating inconsistencies, businesses can enhance their product reliability and maintain brand reputation in the market.

Faster Production Cycles and Increased Efficiency

Time is a critical factor in manufacturing. A plastic molding company optimizes production speeds without compromising on quality, allowing businesses to meet tight deadlines.

1. Automated Processes: With minimal manual intervention, production cycles are faster and more efficient.

2. Multi-Cavity Molds: These molds allow multiple parts to be produced simultaneously, significantly reducing lead times.

3. Just-in-Time Manufacturing: Many plastic molding companies implement lean manufacturing principles, ensuring components are produced only when needed, reducing inventory costs.

By increasing production speed, businesses can meet market demands more efficiently, gaining a competitive advantage.

Cost-Effective Manufacturing Solutions

Reducing production costs while maintaining quality is a priority for every business. A plastic molding company helps achieve this goal in several ways:

1. Material Efficiency: Advanced molding techniques ensure minimal material wastage, making production more sustainable and cost-effective.

2. Bulk Production Benefits: Large-scale manufacturing reduces per-unit costs, making plastic molding a financially viable option.

3. Energy-Efficient Processes: Many plastic molding companies utilize energy-saving technologies to lower operational expenses.

With reduced labor costs, efficient resource utilization, and streamlined workflows, businesses can enjoy long-term cost savings without sacrificing quality.

Expertise in Material Selection for Durability and Performance

Choosing the right plastic material is crucial for product performance and longevity. A plastic molding company offers expert guidance on material selection based on industry requirements and application needs.

Common Plastic Materials Used in Injection Molding:

1. ABS (Acrylonitrile Butadiene Styrene) – Known for its toughness and impact resistance.

2. Polypropylene (PP) – Lightweight and chemical-resistant, ideal for packaging and medical applications.

3. Polycarbonate (PC) – Offers high durability and transparency, commonly used in automotive and electronics.

4. Nylon (PA) – Strong and wear-resistant, used in mechanical and industrial applications.

By selecting the right material, businesses can ensure their products meet durability, safety, and performance standards.

Customization and Product Innovation

Every business has unique requirements, and a plastic molding company provides custom solutions tailored to specific product needs.

1. Prototyping and Product Development: Companies use 3D printing and prototype molds to test and refine designs before full-scale production.

2. Customization for Various Industries: Whether for medical devices, automotive components, or consumer products, custom plastic molding solutions ensure the final product meets exact specifications.

3. Innovative Mold Designs: Advanced engineering allows for complex geometries, overmolding, and multi-component designs to enhance functionality and aesthetics.

With the ability to customize products according to industry needs, businesses can create unique and innovative plastic components that set them apart from competitors.

Conclusion: A Strategic Partner for Business Success

A plastic molding company is more than just a manufacturing service—it is a strategic partner that helps businesses optimize production, reduce costs, and maintain quality. By leveraging advanced technology, expertise, and sustainable practices, plastic molding companies play a crucial role in streamlining manufacturing processes across various industries.

Whether you need high-volume production, custom designs, or eco-friendly solutions, choosing the right plastic molding company can be a game-changer for your business. With the right partnership, you can enhance efficiency, improve product quality, and stay ahead in today’s competitive market.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.