Understanding Flange Weight and Dimensions: A Comprehensive Guide

Flanges are essential components in piping systems, serving as connectors for pipes, valves, and other equipment. They are crucial for facilitating assembly, disassembly, and maintenance while ensuring the integrity and efficiency of the system. When it comes to selecting the right flange for your application, understanding flange weight and dimensions is paramount. In this guide, we’ll delve into the importance of flange weight and dimensions and explore a comprehensive flange weight and dimensions chart.

Importance of Flange Weight and Dimensions

Flanges come in various shapes, sizes, and materials to accommodate pressure, temperature, and corrosive conditions. Therefore, having accurate information about their weight and dimensions is crucial for several reasons:

Compatibility:

Flanges must match the dimensions of the connecting pipes and equipment to ensure proper alignment and sealing. Mismatched dimensions can lead to leaks, inefficiencies, and even system failures.

Load-bearing Capacity:

Understanding the weight of a flange is essential for assessing its load-bearing capacity. Flanges are subjected to internal pressure, external forces, and the weight of the connected components, making it crucial to select flanges capable of withstanding these loads.

Transport and Handling:

Flange weight determines the ease of transportation, handling, and installation. Heavy flanges may require special equipment and procedures for lifting and positioning, adding complexity and cost to the installation process.

Cost Considerations:

The weight and dimensions of flanges can influence material costs, transportation expenses, and installation labour. Selecting flanges that balance performance and cost is essential for optimizing project budgets.

Understanding Flange Weight and Dimensions Chart

A flange weight and dimensions chart provides comprehensive information about various types of flanges, including their dimensions, weights, pressure ratings, and materials. Here’s a breakdown of the key components typically included in such a chart:

Flange Type:

The chart categorizes flanges based on their design, such as slip-on, weld neck, socket weld, threaded, blind, lap joint, etc.

Pressure Rating:

Each flange type is rated for specific pressure levels, typically in pounds per square inch (psi) or bar. The chart provides pressure rating information to ensure compatibility with the operating conditions.

Nominal Size:

Flanges come in standard nominal sizes ranging from 1/2 inch to several feet in diameter. The chart lists the nominal sizes available for each flange type.

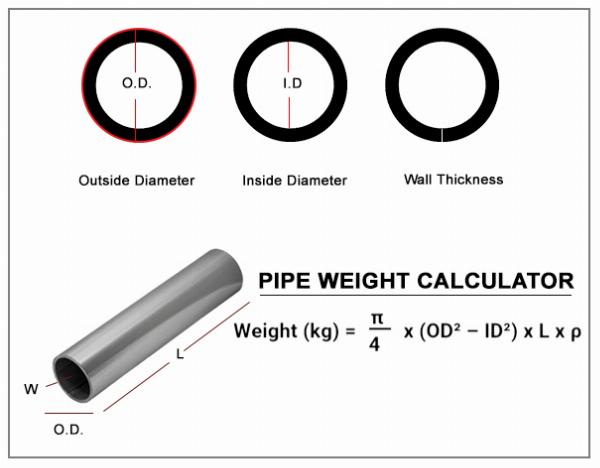

Dimensions:

Detailed dimensions of each flange type are provided, including outside diameter (OD), inside diameter (ID), bolt circle diameter (BCD), bolt hole diameter (BHD), thickness, and overall height.

Weight:

The weight of each flange variant is specified in pounds (lbs) or kilograms (kg), enabling users to assess its load-bearing capacity and transportation requirements.

Material Specification:

Flanges are available in various materials, including carbon steel, stainless steel, alloy steel, and exotic alloys. The chart specifies the material grade or specification for each flange type.

Conclusion

Flange weight and dimensions play a crucial role in piping system selection, installation, and performance. By referring to a comprehensive flange weight and dimensions chart, engineers, designers, and procurement professionals can make informed decisions regarding flange selection, ensuring compatibility, safety, and cost-effectiveness. Whether for a small-scale plumbing system or a large industrial application, understanding flange weight and dimensions is essential for the success of any piping project.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.