Infographics for Backlinks – Visual Goldmines for Authority Sites!

Infographics for Backlinks – Visual Goldmines for Authority Sites!

Unravelling the Advantages of Automated Conveyor Belt Systems

Written by Website » Updated on: June 17th, 2025

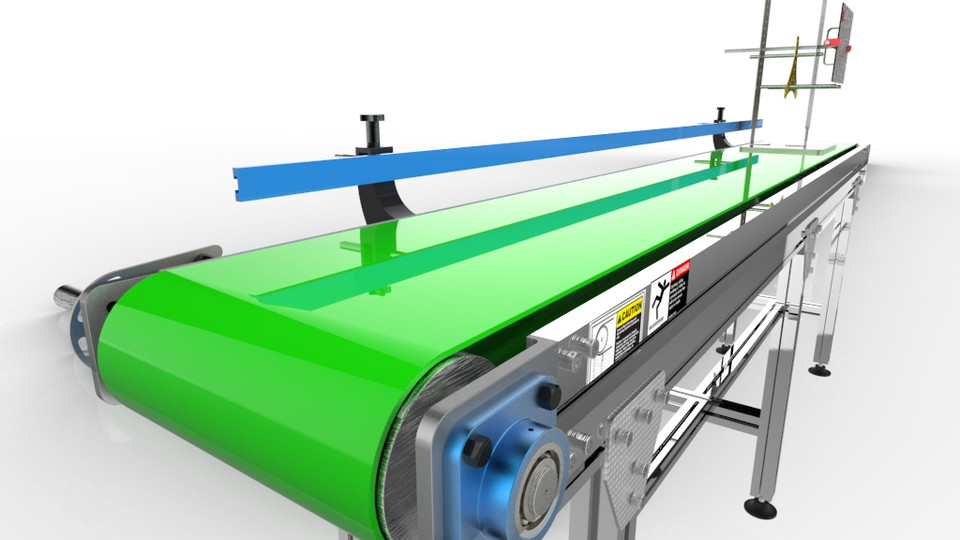

In the bustling realm of modern manufacturing and logistics, efficiency reigns supreme. Businesses constantly seek innovative solutions to streamline processes, reduce costs, and enhance productivity. One such solution that has revolutionized the industry is the automated conveyor belt system. These sophisticated systems have become indispensable assets for various industries, offering a plethora of advantages that propel operations to new heights of efficiency and effectiveness.

Enhanced Productivity: Automated conveyor belt systems excel in expediting material handling processes. By seamlessly transporting goods from one point to another, these systems eliminate the need for manual labor and significantly reduce the time required to move items across a facility. With consistent and uninterrupted operation, productivity levels soar, allowing businesses to meet demanding production schedules and customer deadlines with ease.

Optimized Workflow: The streamlined design of automated conveyor belt systems ensures a smooth and continuous flow of materials throughout the production or distribution process. Unlike traditional methods that rely on human intervention, these systems operate tirelessly, minimizing the risk of bottlenecks and delays. As a result, workflow efficiency is maximized, allowing operations to run seamlessly from start to finish.

Improved Safety: Safety is paramount in any work environment, and automated conveyor belt systems offer notable advantages in this regard. By reducing the need for manual handling of heavy or hazardous materials, these systems mitigate the risk of workplace injuries and accidents. Additionally, advanced safety features such as emergency stop buttons, motion sensors, and protective barriers further enhance worker safety, providing peace of mind for employers and employees alike.

Space Optimization: In today's increasingly crowded industrial facilities, space optimization is a key consideration. Automated conveyor belt systems are designed with efficiency in mind, utilizing vertical space and compact layouts to maximize the use of available floor space. By minimizing the footprint required for material handling equipment, businesses can make more efficient use of their facility, allowing for expanded production capacity or additional storage areas.

Accuracy and Precision: Precision is essential in modern manufacturing and distribution processes, and automated conveyor belt systems deliver unparalleled accuracy in material handling. With advanced sensors and control systems, these systems can precisely control the movement, positioning, and sorting of goods, ensuring that each item reaches its intended destination with pinpoint accuracy. This level of precision minimizes errors and reduces the likelihood of costly rework or product damage, ultimately enhancing overall operational efficiency.

Adaptability and Scalability: One of the greatest advantages of automated conveyor belt systems is their inherent adaptability and scalability. Whether a business is handling small components or oversized goods, these systems can be customized to accommodate a wide range of products, shapes, and sizes. Furthermore, as business needs evolve and production volumes fluctuate, automated conveyor belt systems can be easily scaled up or down to meet changing demands, providing unparalleled flexibility for growth and expansion.

Cost Savings: While the initial investment in automated conveyor belt systems may seem significant, the long-term cost savings they offer are undeniable. By reducing labor costs, minimizing material waste, and optimizing energy consumption, these systems deliver substantial returns on investment over time. Moreover, the enhanced efficiency and productivity they provide can lead to increased revenue generation and improved profitability, further solidifying their value proposition for businesses.

In conclusion, automated Conveyor Pulleys systems represent a cornerstone of modern manufacturing and logistics, offering a multitude of advantages that drive operational excellence and business success. From enhanced productivity and optimized workflow to improved safety and cost savings, the benefits of these systems are undeniable. As industries continue to evolve and embrace automation, the adoption of automated conveyor belt systems will undoubtedly remain a pivotal strategy for achieving competitive advantage in the global marketplace.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.