DA 70+ Guest Post Placements – Elite Authority at Your Fingertips!

DA 70+ Guest Post Placements – Elite Authority at Your Fingertips!

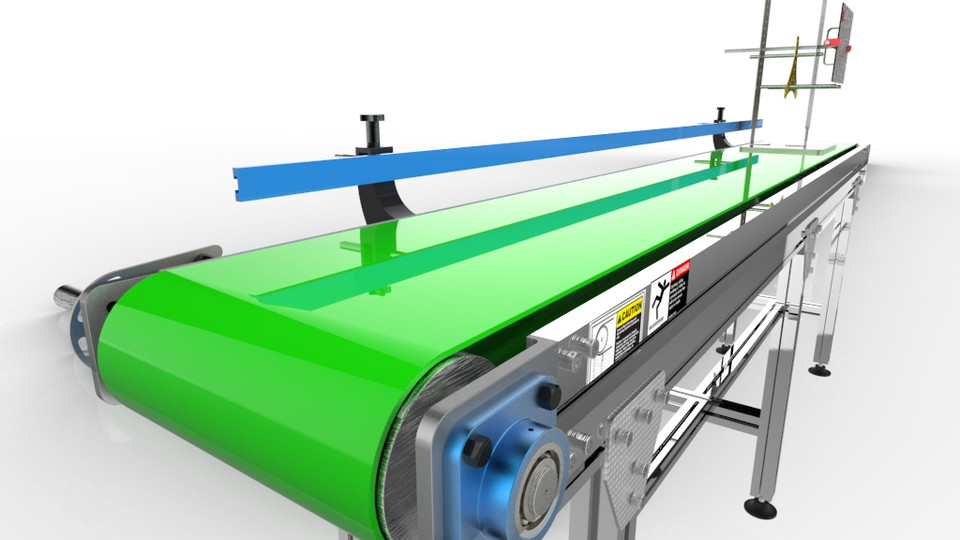

Troubleshooting the Top Common Conveyor Belt Problems with TSGlobal

Written by Website » Updated on: June 17th, 2025

Introduction:

Conveyor belts are a crucial component in various industries, facilitating the smooth flow of materials and products. However, like any machinery, conveyor belts can encounter problems that disrupt operations and lead to downtime. In this article, we will explore some of the most common conveyor belt problems and discuss how TSGlobal, a leading brand in conveyor belt solutions, addresses these issues.

Material Spillage:

One prevalent issue is material spillage along the conveyor belt, causing a messy and potentially hazardous working environment. TSGlobal tackles this problem by designing conveyor belts with enhanced containment features. These features prevent materials from escaping, ensuring a cleaner and safer workspace.

Belt Misalignment:

Misalignment of the conveyor belt can result in uneven wear and tear, leading to frequent replacements and increased maintenance costs. TSGlobal's conveyor belts are equipped with advanced tracking systems that automatically adjust and maintain proper alignment. This feature minimizes the risk of misalignment, ensuring the longevity of the conveyor belt.

Belt Slippage:

Belt slippage can occur due to various reasons, including inadequate tension and excessive load. TSGlobal addresses this issue by providing conveyor belts with optimal tension control mechanisms. These mechanisms help maintain proper tension, preventing slippage and ensuring consistent and efficient material transportation.

Material Jams:

Material jams are a common problem that can disrupt the flow of materials and cause damage to the conveyor belt. TSGlobal incorporates intelligent sensors and controls in their conveyor systems to detect potential jams and automatically adjust the operation to prevent or clear them. This proactive approach minimizes downtime and enhances overall system efficiency.

Belt Wear and Tear:

Over time, conveyor belts experience wear and tear, reducing their lifespan. TSGlobal employs high-quality materials and innovative designs to manufacture conveyor belts that resist wear and tear, resulting in longer service life and reduced replacement frequency. This not only saves costs but also contributes to sustainable and efficient operations.

Excessive Noise:

Excessive noise generated by conveyor belts can be a concern for both workers and the surrounding environment. TSGlobal prioritizes the development of conveyor systems with noise reduction features, ensuring a quieter and more comfortable workplace. This focus on noise control aligns with the brand's commitment to promoting a healthy and safe working environment.

Inadequate Cleaning:

Conveyor belts can accumulate debris and contaminants, impacting product quality and conveyor performance. TSGlobal designs its conveyor systems with easy-to-clean features, facilitating efficient maintenance and preventing the buildup of materials that can compromise system functionality.

Overheating Motors:

Overheating motors are a potential risk that can lead to system failures. TSGlobal integrates advanced temperature monitoring and control systems into its conveyor systems to prevent motor overheating. This ensures reliable and safe operation, reducing the likelihood of unexpected downtime.

Conclusion:

In the world of conveyor systems, addressing common problems is crucial for maintaining efficiency and productivity. TSGlobal stands out as a reliable and innovative brand, consistently developing solutions to combat the most prevalent conveyor belt issues. By investing in TSGlobal's conveyor systems, industries can not only mitigate common problems but also benefit from enhanced performance, extended lifespan, and a more sustainable approach to material handling. With TSGlobal, businesses can confidently navigate the challenges of conveyor belt operation, ensuring smooth and reliable material transportation.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.