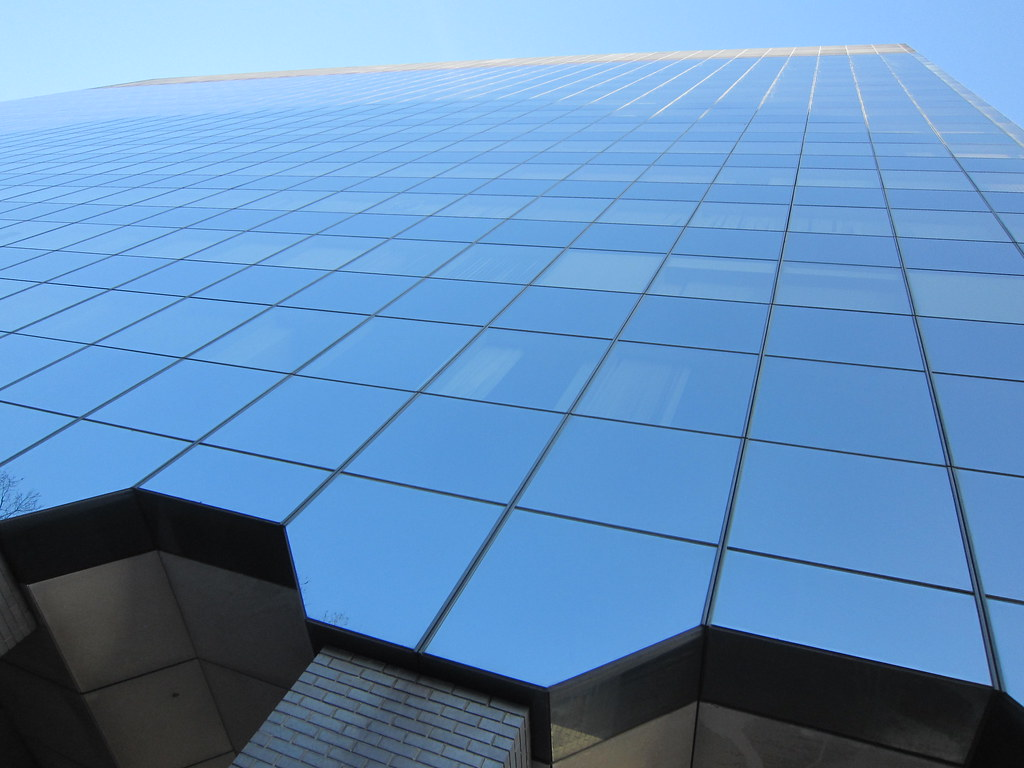

What Glass Should Be Used in the Building Construction?

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The choice of glass for exterior walls of buildings depends on several factors including climate, building design, energy efficiency requirements, and aesthetic preferences. Here are some common types of glass used for exterior walls:

1.Float glass:

Float glass or soda lime glass is the main type of glass panel used in construction; most other glass types are made by adding coatings to float glass panels or modifying the standard float glass composition or method. Float glass is made with calcium silicate and sodium silicate. The name comes from the production process: molten glass is poured onto a bed of molten tin, where it floats. The liquids repel one another so that the floating glass spreads to cover the level surface on top of the melted metal. When the glass cools, it sets hard without bonding to the tin. Then, it can be removed and processed.

Float glass can be made in thicknesses ranging between 2 mm and 20 mm, and generally weighs between 6 kg and 36 kg / m2. Untreated float glass can be cut with hand glass cutting tools easily.

2.Insulated Glass:

Insulated glass units (IGUs) consist of two or more glass panes separated by a spacer, typically filled with a desiccant to prevent condensation.

The space between the panes is filled with an inert gas such as argon or krypton, which reduces heat transfer through the glass.

IGUs provide better insulation compared to single-pane glass, reducing heating and cooling costs in buildings.

3.Low-E Glass:

Low-emissivity (Low-E) glass has a microscopically thin coating applied to one or more surfaces of the glass.

This coating reflects heat, reducing the amount of infrared and ultraviolet radiation that passes through the glass while allowing visible light to transmit.

Low-E glass helps maintain consistent indoor temperatures, reduces glare, and protects interior furnishings from fading due to UV exposure.

4.Tempered Glass:

Tempered glass is produced through a process of controlled thermal or chemical treatment, making it stronger and more impact-resistant than regular glass.

In the event of breakage, tempered glass shatters into small, blunt fragments, reducing the risk of injury compared to sharp shards.

It's commonly used in exterior walls where safety and durability are paramount, such as glass doors, windows, and curtain walls.

5.Laminated Glass:

Laminated glass consists of two or more layers of glass bonded together with an interlayer, typically made of polyvinyl butyral (PVB).

The interlayer holds the glass together in case of breakage, providing safety and security benefits.

Laminated glass also offers sound insulation properties, UV protection, and can be manufactured with varying levels of thickness and interlayer materials for specific performance requirements.

6.Tinted or Reflective Glass:

Tinted glass contains additives that alter its color and reduce the transmission of visible light and solar heat.

Reflective glass has a metallic or reflective coating applied to the surface, which reflects a portion of the solar radiation.

Both tinted and reflective glasses help improve comfort by reducing glare and solar heat gain, but they may impact visibility and aesthetics.

7.Curtain Wall Systems:

Curtain walls are non-load-bearing exterior walls made of lightweight materials such as glass, aluminum, or steel.

They provide an aesthetic façade while allowing natural light to enter the building.

Curtain wall systems can incorporate various types of glass, including insulated, low-E, or laminated glass, depending on design requirements and performance criteria.

8.Self-Cleaning Glass:

Self-cleaning glass features a hydrophilic or photocatalytic coating that breaks down organic dirt and pollutants when exposed to sunlight.

Rainwater spreads evenly over the surface, washing away the loosened dirt and leaving the glass cleaner for longer periods.

Self-cleaning glass reduces the need for manual cleaning and maintenance, particularly in hard-to-reach exterior locations.

When selecting glass for exterior walls, architects and engineers consider factors such as energy efficiency, safety, aesthetics, maintenance requirements, and local building codes to ensure the chosen glass type meets the project's specific needs.

HHG is a professional glass manufacturer and glass solution provider that includes a range of tempered glass, laminated glass, textured glass, and etched glass. With more than 20 years of development. There are two produce lines of pattern glass, two lines of float glass, and one line of restoration glass. Our products are 80% shipped overseas. All our glass products have strict quality control and are carefully packed in strong wooden cases. Ensuring you receive the finest quality glass safely in time.

More Details: www.hhglass.com

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.