A Comprehensive Guide to Understanding Slitter Cutters and Their Uses

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Slitter cutters are the most significant tools in several industries because they provide the utmost necessity of precision cutting in those materials. These tools are made to slit or cut paper, metals, plastics, and fabrics into smaller shapes or manageable sizes. The two are powerful and highly effective versatile tools in manufacturing and processing. In this article, we will discuss the Slitter Cutters and their uses.

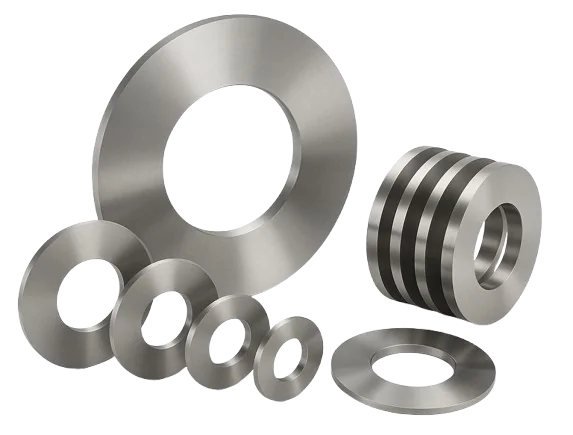

1. What Are Slitter Cutters?

A slitter cutter is a machine tool or equipment that has specialized features to slit or cut materials into narrower widths. Its design incorporates rotating blades or sharp cutting edges that slice cleanly through materials. The devices help minimize waste, are coupled with high precision, and are hence highly suitable for industries with applications that require accuracy to a high degree.

2. Types of Slitter Cutters

Several types of slitter cutters are designed to meet specific applications.

- Rotary Slitter Cutters: This is a circular blade cutter, usually used in high-speed applications.

- Razor Slitter Cutters: Sharp razors are used on them, and they can even be sliced for very thin objects, like films and foils.

- Shear Slitter Cutters: They resemble scissors; they are designed to cut in heavier materials such as metals and plastics.

- Score Slitter Cutters: This creates an indentation or crease but does not cut the material fully. It is typically used in packaging.

Each type has its special advantages and is suitable for certain materials and industries.

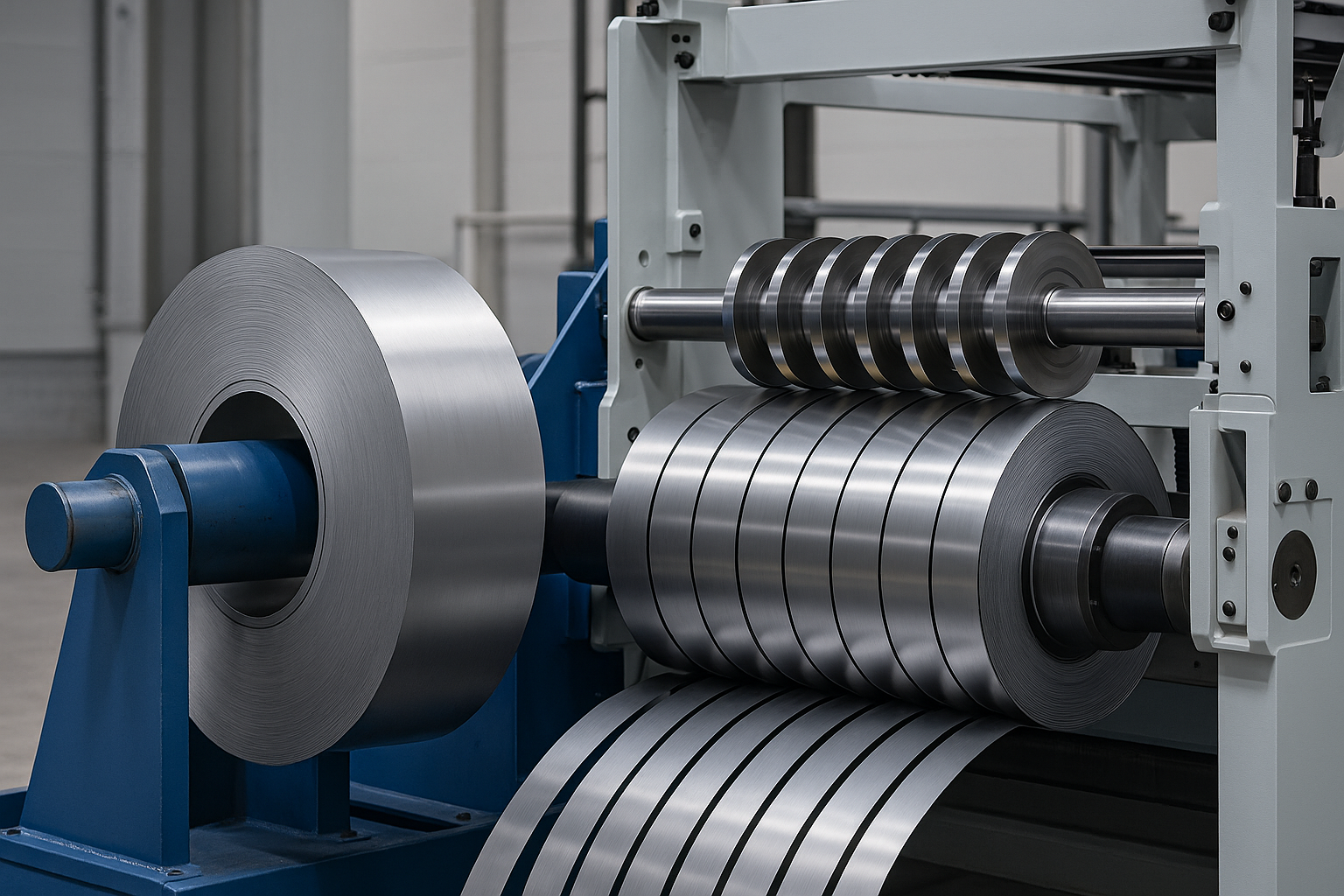

3. Working Principle of Slitter Cutters

Slitter cutters work on the basis of speed, precision, and sharpness of the blades. The material passes through a number of rollers and blades, which cut it into the desired width or pattern. The process is highly automated in modern machines, so it ensures consistency and reduces manual errors.

4. Applications of Slitter Cutters

Here are the uses of slitter cutters:

- Packaging Industry: In packaging, a Slitter Cutter is used to cut film, foil, and paper into the precise size required for the wrapping of products.

- Printing and Publishing: Slitter cutters ensure that paper and other materials are trimmed to the exact dimensions required for printing and publishing.

- Textile Industry: For fabrics and other textiles, slitter cutters provide precise cuts that enhance the efficiency of garment manufacturing.

- Metal Processing: In metal industries, the slitter cutters trim sheets and rolls into specified dimensions with great accuracy.

- Plastic and Polymer Processing: Plastic films, sheets, and other polymer-based materials are trimmed using slitter cutters for products like bags, packaging, etc.

5. Benefits of Using Slitter Cutters

Slitter cutters have numerous benefits that make them indispensable in manufacturing and processing:

- Precision: It ensures the cuts are precise, hence minimal waste.

- Efficiency: Speeds up the production process significantly.

- Versatility: Works with a wide range of materials.

- Cost-Effective: Reduces material waste and labor costs.

- Customizability: Modern slitter cutters allow adjustments for different cutting patterns and material types.

6. Choosing the Right Slitter Cutter

When selecting a slitter cutter, several factors need to be considered:

- Material Type: Ensure compatibility with the material being cut.

- Blade Type: Different materials require specific blade types for optimal performance.

- Speed Requirements: High-speed operations require sturdy and efficient machines.

- Maintenance Needs: Choose a machine with easily replaceable parts and minimal maintenance needs.

7. Maintenance and Longevity of Slitter Cutters

Slitter cutters need to be maintained regularly to last longer and perform well. These include:

- Blade Sharpening: Dull blades can compromise precision and efficiency.

- Lubrication: This keeps the machine running smoothly.

- Inspection: Periodic checks help identify wear and tear early.

Cleaning prevents debris from building up, which may affect performance.

8. Slitter Cutter Advances

As technology advances, so do slitters and cutters. Features, including automated adjustments, real-time monitoring, and improved safety features, are changing the landscape with which these tools are implemented in industries.

9. Safety Precautions

Operating slitter cutters requires the following safety precautions so that accidents do not take place:

- Wear personal protective equipment.

- The machine should be switched off for blade changes.

- Maintain hands and garments as far away from the machine as possible.

Machine Regular checks of the machinery are required to find possible dangers.

10. Future Trends in Slitter Cutter Applications

When businesses transform, slitter cutters will become more critical components to enhance efficiency while lowering waste. With new concepts about green manufacturing practices emerging, these machines will also transform into cutting environment-friendly materials without compromising the rate or accuracy.

Conclusion

A Slitter Cutter is one of the crucial needs for businesses, as they require the precision cutting of various materials. From packing to textiles, metal processing to others, this is where efficiency and versatility come to unmatched standards. Maxwell Slitter Industries is a trusted name because of customer satisfaction, ensuring that businesses receive the best Slitter Cutters for their operations and empowering achievement of excellence in operation.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.