Industrial Blades: Types, Applications, and Selection Tips for Manufacturers

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In the manufacturing world, precision, durability, and efficiency define success. One tool that plays a pivotal role in ensuring all three is the industrial blade. Whether used in food processing, metal slitting, plastic shaping, or textile cutting, industrial blades are essential for high-performance operations. Choosing the right blade not only improves output quality but also minimizes downtime, waste, and operational costs.

This comprehensive guide explores the types of industrial blades, their diverse applications across industries, and key tips manufacturers should consider when selecting the perfect blade for their needs.

What Are Industrial Blades?

Industrial blades are specialized cutting tools designed for use in industrial machinery. Unlike household blades, these tools are engineered to handle high-volume cutting, slicing, slitting, and shearing tasks under extreme conditions. These blades are typically made from high-carbon steel, stainless steel, tungsten carbide, or ceramic materials to ensure longevity, sharpness, and resistance to corrosion and wear.Common Types of Industrial Blades

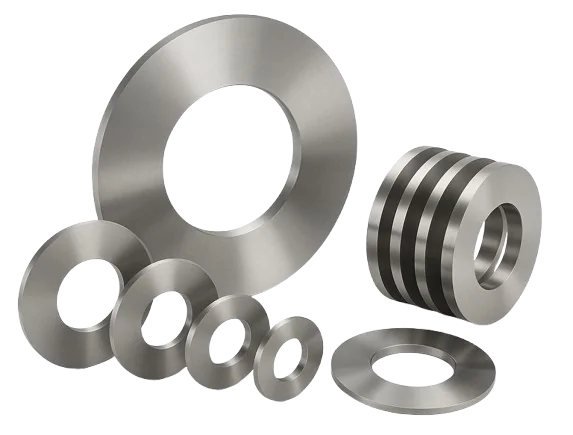

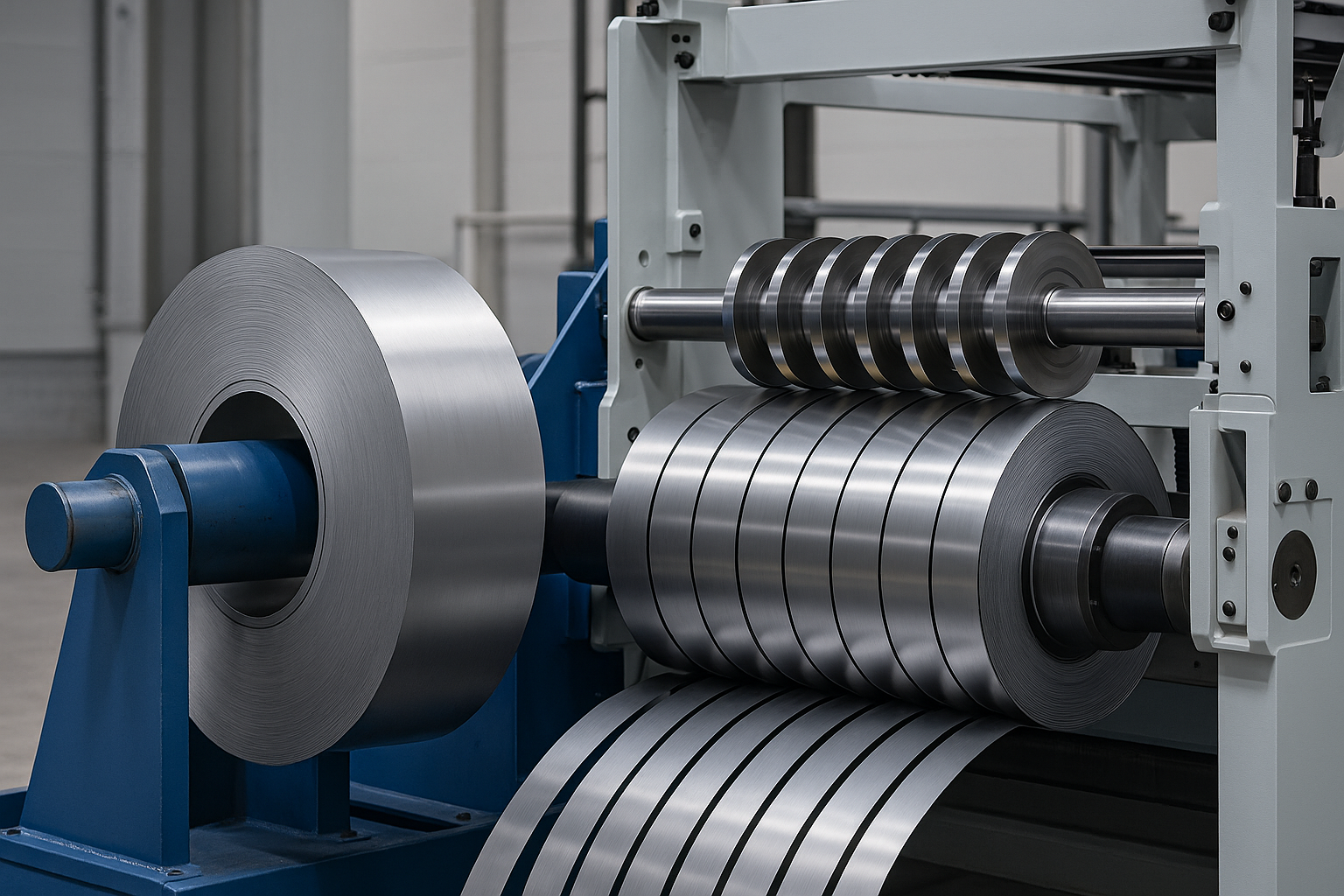

There is no one-size-fits-all when it comes to industrial cutting. Different industries require different blade types, each tailored to specific materials and processes. Here are the most commonly used types of industrial blades:1. Slitter Blades

Slitter blades are used for slitting or cutting materials into narrow strips. They are commonly used in paper, plastic film, and metal industries. These blades need to be incredibly sharp and durable to provide clean, straight cuts without fraying or distortion.2. Shear Blades

Shear blades are designed to cut sheet metal and other tough materials with precision. They operate using a scissor-like action and are typically used in steel manufacturing, automotive, and construction industries.3. Guillotine Blades

These are heavy-duty blades used in guillotine-style machines. Commonly found in printing and packaging industries, guillotine blades can be cut through stacks of paper, cardboard, or thin metal sheets with a single downward stroke.4. Circular Knives

Circular knives or rotary blades are round, disk-like cutting tools used for continuous cutting applications. These are commonly used in textiles, foam, rubber, and food processing.5. Toothed Blades

Toothed blades resemble saw blades and are used when cutting thicker or more rigid materials, such as wood, plastic, or rubber. Their teeth can be fine or coarse, depending on the level of precision required.6. Straight Blades

These are flat-edged blades used in machine tools for trimming, cutting, and processing sheets of various materials. Their simple design makes them highly versatile across industries.Industries That Rely on Industrial Blades

Industrial blades are essential in a wide range of sectors. Each industry requires blades that match their unique materials and production goals:1. Paper and Packaging Industry

Slitter and guillotine blades are widely used for cutting, scoring, and trimming paper products. In the packaging industry, precision blades help shape boxes, labels, and flexible packaging without damaging the product.2. Metal Processing Industry

Shear and slitter blades are crucial for cutting metal sheets, rods, and wires. These blades must withstand high pressure and resist wear, especially when cutting harder metals like stainless steel or aluminium.3. Food Processing Industry

Blades used in this sector must meet stringent hygiene standards. Circular knives and straight-edge blades are common here, used to slice meats, vegetables, baked goods, and more. Stainless steel is the preferred material due to its rust-resistant and food-safe properties.4. Plastic and Rubber Manufacturing

From shaping plastic sheets to cutting rubber gaskets, toothed and straight blades play a vital role in these sectors. The challenge lies in selecting blades that offer clean cuts without overheating or deforming the material.5. Textile Industry

Rotary and circular knives are used to cut fabrics with high precision and minimal fraying. The textile industry demands blades that stay sharp for extended periods to keep production lines running smoothly.Choosing the Right Industrial Blade: Tips for Manufacturers

Selecting the right blade is critical to the efficiency and cost-effectiveness of your operation. Here are some expert tips to help manufacturers make the best choice:1. Know Your Material

Different materials require different blade types. Cutting metal differs significantly from slicing paper or fabric. Consider the hardness, thickness, and texture of your material when choosing a blade.2. Blade Material Matters

Choose blade materials based on durability, corrosion resistance, and sharpness retention. For instance, tungsten carbide blades last longer and are ideal for cutting abrasive materials. Stainless steel is an excellent option for hygienic and rust-resistant applications, especially in the food industry.3. Check Compatibility with Machinery

Ensure the blade fits your equipment and is compatible with the machine’s speed, pressure, and torque. A mismatched blade can lead to inefficient cutting, damage to the machinery, or frequent blade replacement.4. Evaluate Blade Coatings

Blade coatings can enhance performance and lifespan. For example, titanium nitride coatings reduce friction and wear. Coated blades are especially useful in high-speed or high-heat cutting environments.5. Maintenance and Sharpening

Opt for blades that are easy to maintain and sharpen. Manufacturers should also invest in high-quality sharpening equipment or partner with a reliable sharpening service to ensure consistent blade performance.6. Consult with Experts

Reputable blade manufacturers like Maxwell Slitters offer consultation services to help you select and customize blades tailored to your operational needs. Partnering with experts ensures you make informed decisions and improve production efficiency.Custom Industrial Blades: A Smart Investment

Off-the-shelf blades may not always meet your unique production requirements. That’s where custom industrial blades come into play. Custom blades are engineered based on your machine specifications, production goals, and material types. Though they may come at a higher initial cost, custom blades can significantly improve cut quality, reduce waste, and minimize downtime in the long run.Conclusion

Industrial blades are the backbone of efficient manufacturing processes across industries. Understanding the different types of blades and their applications allows manufacturers to choose the best tools for their specific needs. From slitter and shear blades to rotary and guillotine knives, each blade plays a crucial role in delivering clean, accurate, and reliable cuts.

To achieve peak production performance, it is vital to select blades based on material compatibility, blade composition, and your machine’s requirements. When in doubt, consult a trusted blade expert who understands the demands of modern manufacturing.

For precision-engineered, high-performance industrial blades trusted by industries worldwide, turn to Maxwell Slitters, your partner in cutting-edge efficiency.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.