Schema + Rich Snippets – Dominate Search with Visual Results!

Schema + Rich Snippets – Dominate Search with Visual Results!

Boosting Productivity with Mitsubishi PLC Self-Resetting Timer

Written by Sanam Iftikhar » Updated on: June 17th, 2025

Introduction

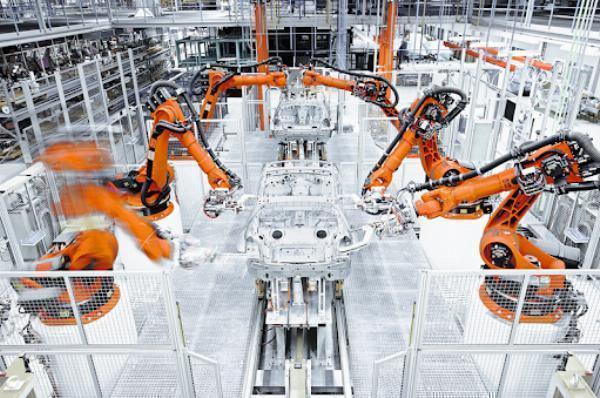

Mitsubishi PLCs (Programmable Rationale Regulators) offer different capabilities to robotize modern cycles, and the self-resetting timer is one of the critical devices to further develop effectiveness and productivity. Via robotizing tedious errands, this timer diminishes personal time, upgrades machine use, and guarantees smooth tasks without manual intercession. This guide makes sense of how utilizing a self-resetting timer in Mitsubishi PLCs can improve productivity in modern conditions.

Outline

Figuring out the Self-Resetting Timer

How It Improves Productivity

Moves toward Carry out the Self-Resetting Timer

Genuine Applications

Conclusion

FAQs

Background

The self-resetting timer in Mitsubishi PLC frameworks is intended to set off an activity after a preset span over and over. When the timer goes full circle, it resets itself and begins once again. This takes into consideration consistent activities, for example, overseeing transport lines, mechanized assessment cycles, or standard support alarms. Computerizing these common assignments saves time as well as limits the gamble of human error, prompting more reliable creation results.

How It Upgrades Productivity

Lessens manual interference: Undertakings that would somehow require human activity can now be completely mechanized, opening up work for additional perplexing assignments.

Keeps up with Consistency: Self-resetting timers guarantee tasks occur at exact spans, keeping up with the consistency and nature of the result.

Limits Personal time: Computerized resets imply that cycles go on without stop, expanding the general throughput of creation lines.

Further develops Gear Life span: By planning customary support undertakings with timers, mileage on hardware can be diminished, prompting less spontaneous margin time.

Moves toward Carry out the Self-Resetting Timer

Set up the timer:

Open Mitsubishi PLC programming like GX Works2.

Utilize the TON (Timer On Postponement) guidance to characterize another timer in the stepping stool rationale.

Indicate a preset worth that decides how long the timer runs prior to resetting.

Consolidate Reset Rationale:

Program an Ordinarily Shut (NC) contact in your rationale that will set off the reset once the timer goes full circle.

Test and streamline:

Subsequent to programming, run the framework to notice the timer's activity. Change the preset time on a case-by-case basis to fit the creation necessities.

Certifiable Applications

Transport line robotization: Self-resetting timers can mechanize transport lines to move items at customary spans without requiring manual control.

Routine Examinations: Timers can be utilized to plan occasional investigations or cautions for quality checks, guaranteeing opportune and customary observing.

Preventive Support: Naturally trigger hardware upkeep errands at set spans to keep away from machine breakdowns.

Conclusion

Utilizing a self-resetting timer in Mitsubishi PLC frameworks is an exceptionally compelling method for boosting productivity in modern cycles. Via mechanizing redundant assignments, decreasing free time, and keeping up with functional consistency, this capability can smooth out creation and lead to expanded effectiveness. Appropriate execution of this component will bring about less manual intercession, further developed hardware execution, and streamlined generally speaking tasks.

FAQs

1. What is the fundamental advantage of a self-resetting timer in a Mitsubishi PLC?

It mechanizes redundant assignments, decreasing manual intercession and further developing productivity.

2. How might a self-resetting timer assist with preventive upkeep?

It can set off customary support activities at preset stretches, guaranteeing opportune examinations and diminishing startling hardware disappointments.

3. What programming do I have to program Mitsubishi PLC timers?

You can utilize GX Works2 or GX Engineer to program timers and different capabilities in Mitsubishi PLCs.

4. Might I at any point change the timer cycle after execution?

Indeed, the preset time can be effortlessly changed in the PLC programming to suit changing cycle needs.

5. In which ventures are self-resetting timers generally regularly utilized?

They are utilized in businesses, for example, fabricating, food handling, and materials taking care of, where mechanization of dull cycles is critical.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.