China's Paper Cutter Machines: Precision, Power & Productivity

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

China has firmly established itself as a global leader in the design and manufacturing of industrial paper cutter machines, producing a comprehensive range of equipment celebrated for its robust performance, technological innovation, and exceptional value. These machines serve as fundamental tools across countless sectors where the precise and efficient cutting of paper, cardboard, labels, films, and other sheet materials is paramount. From bustling print shops and nimble design studios to high-volume packaging plants and converting facilities, Chinese paper cutters deliver the critical combination of accuracy, reliability, and productivity required in modern industrial operations.

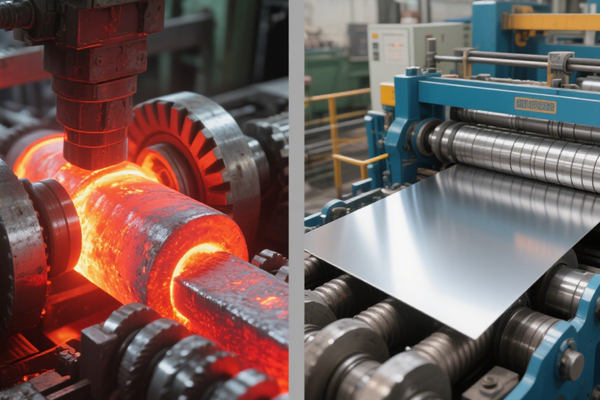

The core function of any paper cutter machine is to cleanly and squarely cut stacks of sheet material to exact dimensions. This is achieved through a powerful blade descending onto material securely held by a clamping mechanism. Chinese manufacturers excel in producing machines across the entire spectrum of cutting technology. Simple manual paper cutters remain popular for low-volume tasks, trimming, and prototyping. Operators manually set the cutting length using a physical gauge on these compact, affordable machines, which offer ease of use through lever or pull-handle operation. While cost-effective and portable, their cutting capacity and speed are inherently limited, relying more on operator skill for high precision.

Moving up the technology ladder, programmable hydraulic paper cutters represent the backbone of many print shops, copy centers, and small-to-medium packaging operations. These machines harness hydraulic power to drive the blade, providing immense cutting force capable of slicing through thick stacks of material. Their defining feature is the digital programmable back gauge, allowing operators to precisely set cut lengths via a keypad interface and store multiple job settings for quick recall. Enhanced safety systems, including two-handed operation buttons and blade guards, are standard. Powerful hydraulic or pneumatic clamps firmly secure the material before the cut. This combination of significant power, good precision, improved speed, and relative affordability makes them highly versatile workhorses suitable for medium to high volumes, offering a substantial leap in consistency and capability over manual models.

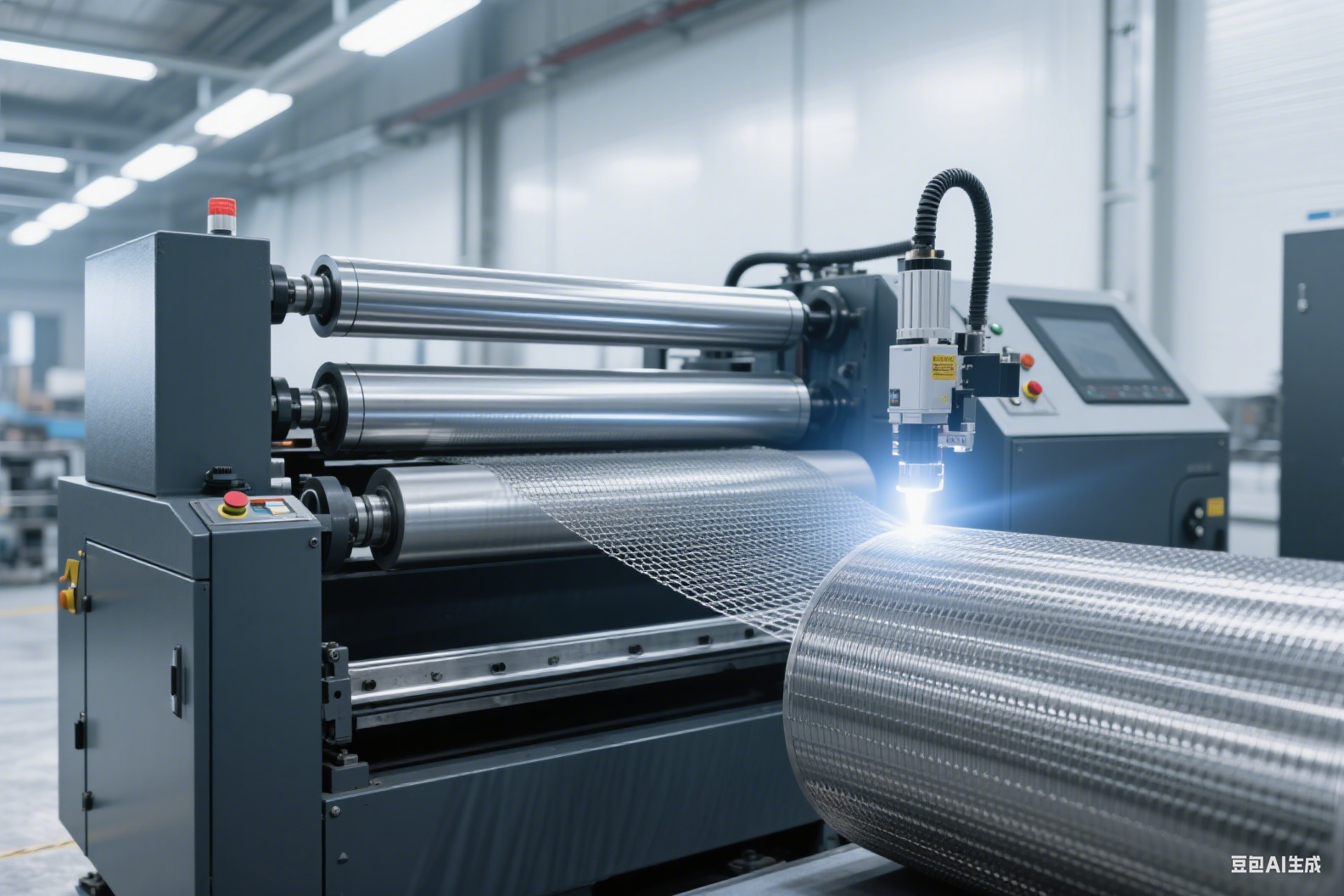

For the most demanding industrial environments, China produces sophisticated fully automatic CNC (Computer Numerical Control) paper cutters. These represent the pinnacle of cutting technology, engineered for high-volume, high-precision production lines where maximum throughput and minimal operator intervention are essential. A central CNC computer controls every aspect of the cutting process – blade descent, clamp pressure, and back gauge positioning – with extreme precision and repeatability. High-precision servo motors rapidly and accurately position the back gauge. Advanced clamping systems automatically optimize pressure for different material types and stack heights. Robust hydraulic systems deliver the high cutting force needed for dense stacks. Crucially, these machines often integrate seamlessly into automated workflows, featuring automatic pile feeders to load material, joggers to align stacks perfectly, and unloaders or conveyors to remove finished pieces. Large capacities allow them to handle very tall stacks consistently, while intuitive touchscreen interfaces facilitate programming, extensive job storage, and real-time production monitoring. The strengths of CNC cutters lie in their unparalleled productivity, precision, repeatability, and their ability to form the core of a fully automated converting line, making them indispensable for large-scale manufacturing.

Distinguishing characteristics define the success of Chinese paper cutter machines in the global market. They offer an outstanding value proposition, providing advanced technology and robust construction at highly competitive price points, making industrial-grade cutting accessible to a broader range of businesses. The sheer breadth of the Chinese market caters to every conceivable need, offering machines from basic manual trimmers to highly sophisticated automated CNC systems, ensuring a suitable solution exists for every budget and application. Chinese manufacturers demonstrate rapid technological adoption, actively incorporating modern features like robust touchscreen controls, energy-efficient servo drives for back gauges, optimized hydraulic systems, and increasingly, IoT connectivity for data monitoring and predictive maintenance. There is a strong emphasis on robust construction, particularly in mid-range and high-end models, utilizing heavy-duty cast iron or welded steel frames, hardened steel blades, and durable components to ensure longevity in demanding industrial environments. Furthermore, many manufacturers offer significant customization options, tailoring cutting lengths, clamping pressures, safety features, or material handling accessories to specific customer requirements. Leading Chinese brands increasingly adhere to stringent international safety standards (like CE) and implement quality control processes aiming for parity with established Western manufacturers.

The application areas for Chinese paper cutters are vast and varied. In printing and publishing, they are essential for precisely trimming books, magazines, brochures, flyers, business cards, and posters, with hydraulic and CNC models dominating this space. The packaging industry heavily relies on them, particularly high-force hydraulic and CNC cutters, for processing corrugated cardboard sheets, folding cartons, labels, and flexible packaging films. Precision is critical in label and sticker production, where machines cut label sheets, rolls, and stickers to exacting standards. Commercial environments like copy centers, print-for-pay shops, and large offices utilize hydraulic cutters for daily trimming tasks. The graphic arts and signage sector employs them for cutting diverse substrates including foam board, PVC sheets, and acrylics. They are fundamental tools in the general converting industry, processing various web or sheet materials like films, foils, and non-wovens for numerous end uses. Finally, institutions such as schools, universities, and government reprographics departments frequently depend on reliable hydraulic cutters.

Choosing a Chinese paper cutter machine offers compelling advantages for businesses worldwide. They deliver significant cost savings in acquisition compared to equivalent machines from Europe or North America. Modern Chinese machines offer proven performance, delivering reliable and precise cutting capabilities suitable for demanding industrial settings. There is a clear trend towards technological parity, with Chinese machines increasingly incorporating the automation, advanced digital controls, and comprehensive safety systems once found only on premium international brands. Major Chinese exporters have also built extensive global dealer and service networks, providing crucial support for parts, maintenance, and technical assistance. Leading brands exemplifying this capability include Qingdao Zhongyou with its exceptionally wide range, Weihai Weitong known for robust hydraulic models and evolving CNC solutions, Shanghai Printyoung with a strong focus on printing and packaging cutters, Dinghao Machinery offering a broad spectrum, and Longshine recognized for reliable hydraulic machines.

In conclusion, China's paper cutter machine industry stands as a testament to sophisticated engineering, offering a powerful blend of precision, durability, and practical innovation. From the straightforward utility of manual cutters to the blazing efficiency and integration capabilities of fully automated CNC systems, Chinese manufacturers provide effective solutions for virtually any industrial cutting requirement involving paper, board, and related sheet materials. Driven by continuous technological advancement, rigorous manufacturing standards, and an unmatched value proposition, these machines empower businesses across the globe to significantly enhance their productivity, elevate product quality, and maintain a competitive edge. For any enterprise seeking reliable, high-performance, and cost-effective cutting equipment, the diverse and technologically advanced offerings from China warrant serious and thorough consideration.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.