The power of automatic cutting and rolling machines.

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

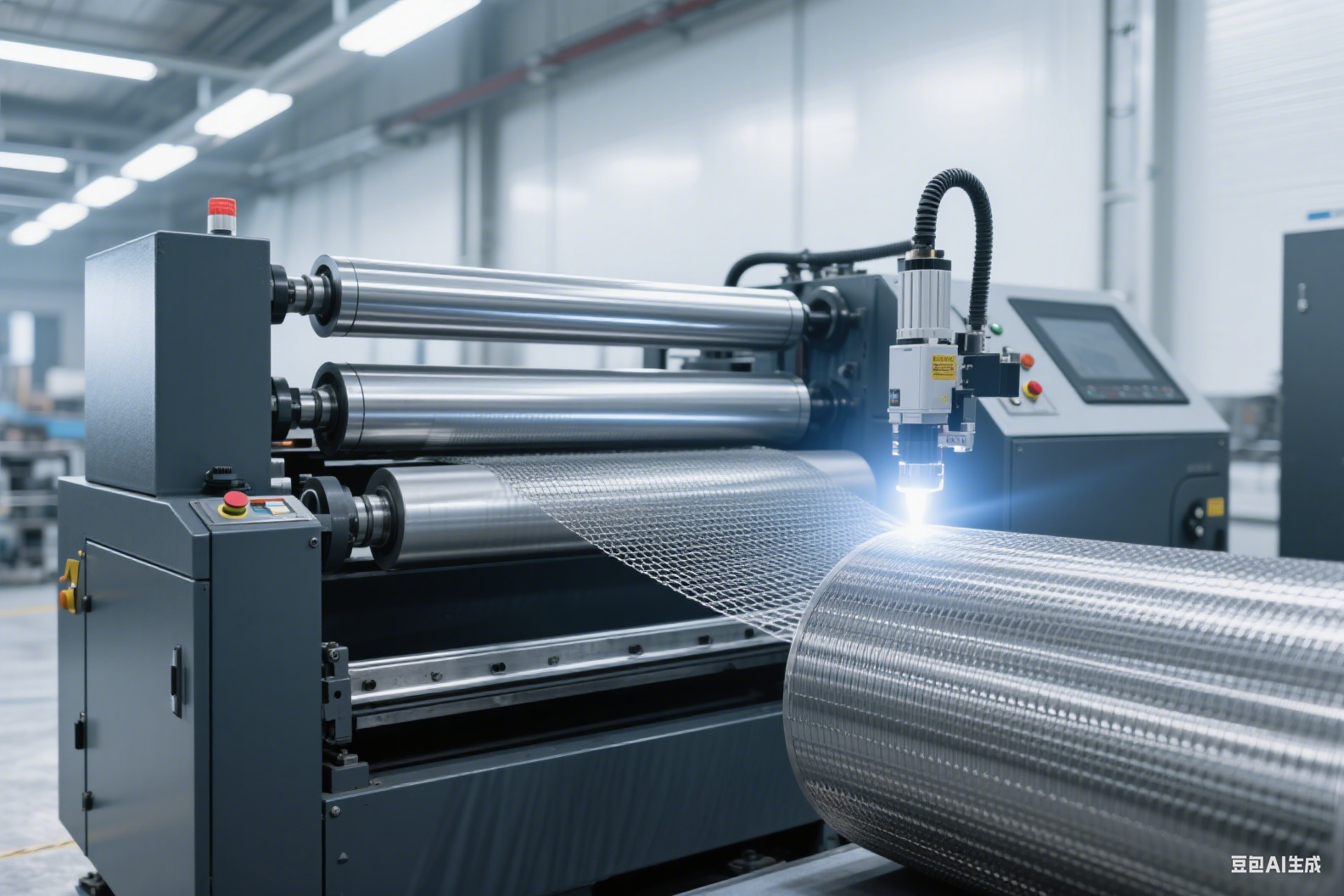

In today's hyper-competitive manufacturing landscape, precision and efficiency aren't just goals—they're survival tools. Entering the automatic cutting and rolling machine is a technical miracle, which redefines the treatment of metal mesh in all industries around the world. This integrated solution seamlessly integrates leveling, cutting and cylindrical forming into an automated workflow, which eliminates bottlenecks and sets new quality standards.

Beyond conventional processing: what is unique about this machine?

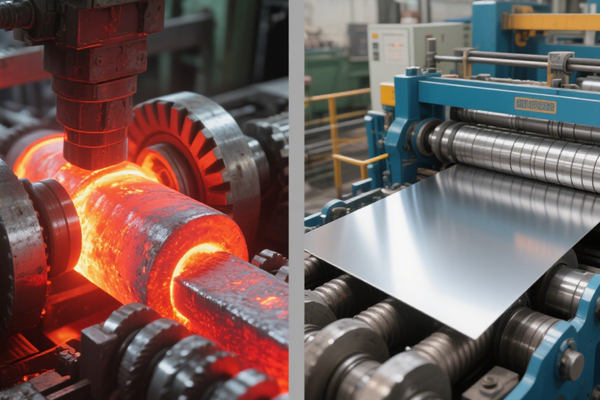

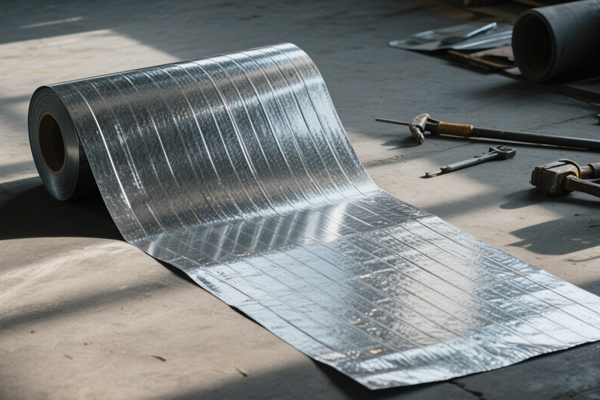

Traditional metal mesh production needs three independent machines: one for flattening, the other for cutting and a third for rolling. Every transmission between stations will introduce errors, waste material and consume productivity. Automatic cutting and rolling machines integrate these functions into an intelligent system. Intelligent leveling is realized by the upper and lower rollers, which can accurately flatten coiled metal net and eliminate the distortion before cutting. Laser-sharp cutting follows, with automated shearing slicing material to exact specifications (± 0.1 mm accuracy), eliminating manual measurement errors. Finally, the machine rolls cut net into seamless cylinder, which is ready for welding or assembly. Operators can adjust parameters such as cutting length or rolling diameter within a few seconds through intuitive touch screen interface without professional training.

Why Industries is turning to automated integration.

The triple threat of space, time and cost savings promote the application. Imagine replacing three machines occupying 30 m² of factory space with one compact unit. Automated material feeding, processing, and ejection achieve:

50% faster production cycles

40% lower labor costs

Near-zero material waste

Accuracy is still another crucial advantage. Traditional methods usually produces irregular cylinder diameters or serrated edges, which affects the integrity of products. This machine ensures perfect surface smoothness to achieve the best sealing, burr-free cutting, no piercing of filter media, and maintains consistent size in batches of 10,000 units. This accuracy is very important for applications such as air filter elements, and a deviation of 0.5 mm can lead to system failure.

The simple operation ensures the success of the transaction. Forget cumbersome levers or manual calibration. The touchscreen HMI (Human-Machine Interface) stores recipes for different mesh types. In less than one minute, the production of 50 mm dust collector net was switched to the production of 120 mm HVAC filters. Real-time diagnosis can even remind the operators that maintenance is needed before stopping.

Where This Technology Transforms Industries.

From cleanrooms to chemical plants, automatic cutting and rolling machines have proved indispensable. In the field of air and liquid filtration, they produce flawless pleated filter cartridges with uniform pleat spacing to achieve maximum air flow efficiency. Manufacturers of industrial dust collector rely on them to roll internal/external support nets to withstand 24/7 wear environment. The HVAC and automotive industries benefit from precision-formed meshes for catalytic converters, exhaust systems, and ventilation ducts. Even architectural applications use these machines to create decorative cylinders with artistic precision for facade, stairwells and safety barriers.

More Than an Upgrade—A Strategic Advantage.

Automatic cutting and rolling machine is not just another piece of factory equipment. This is a complete reimagination of metal manufacturing-the integration of precision, automation and versatility. For manufacturers eyeing scalability and resilience, this technology delivers compromised quality in high-volume production, radical cost efficiency from material to manpower, and future-ready adaptability for evolving industry standards. As supply chains becomes more and more complicated, investment integration automation is not an option. This is the blueprint for staying ahead.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.