CNC_vs_Manual_Knife_Pleating_Machines

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The evolution of industrial filtration systems has always been closely tied to advancements in pleating technology. At the heart of modern filter manufacturing lie two distinct yet complementary solutions: the CNC Knife Pleating Machine and its conventional counterpart, the manual Knife Pleating Machine. These systems represent different generations of engineering philosophy, each with unique advantages that cater to specific production requirements.

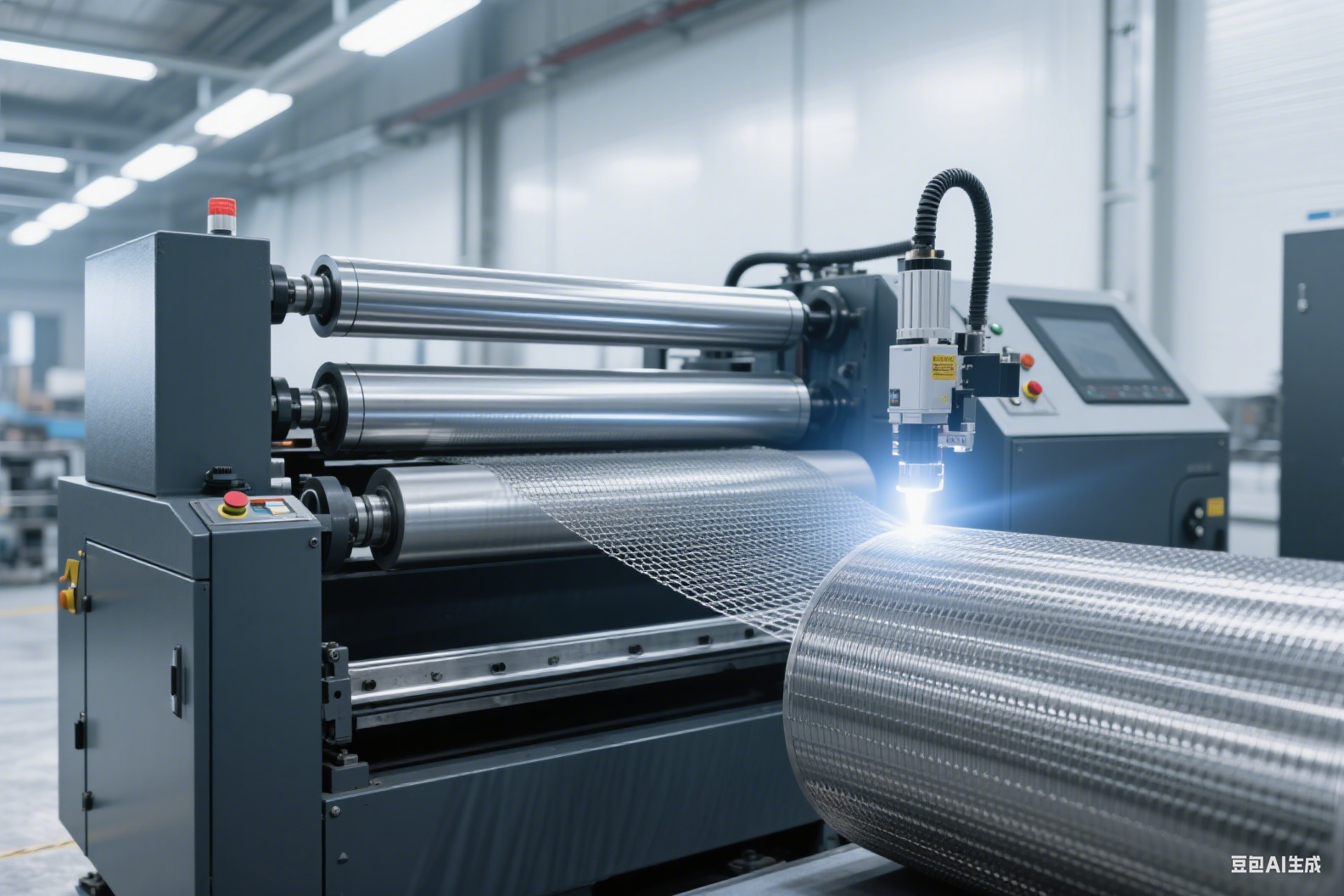

Pleating technology fundamentally transforms flat materials into engineered three-dimensional structures through precise folding patterns. The CNC variant represents the pinnacle of automation in this field, where computer-controlled upper and lower knives perform alternating folding operations with micron-level precision. Unlike traditional models that rely on mechanical stops and manual adjustments, the CNC system dynamically calculates optimal knife positioning based on material properties and desired pleat geometry. This allows for real-time compensation of material thickness variations that commonly occur in multilayer composite fabrics or metal meshes. Industrial case studies demonstrate that CNC-controlled pleating achieves dimensional accuracy within ±0.01mm, a critical requirement for high-performance hydraulic filters where uneven pleats can reduce filtration efficiency by up to 30%.

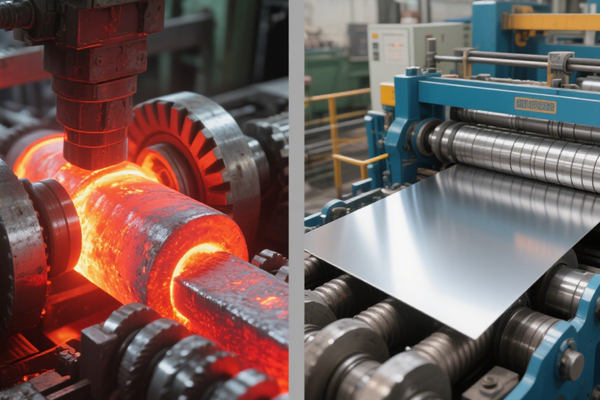

Conventional knife pleating machines maintain relevance through their mechanical simplicity and material versatility. While lacking computerized controls, their robust construction enables processing of unconventional materials like heavy curtain fabrics that might challenge automated systems. The manual adjustment mechanism, though requiring skilled operators, provides tactile feedback that some manufacturers prefer when working with delicate or unpredictable materials. Thermal stabilization options available on both systems address the memory effect in synthetic fabrics, but the CNC version integrates this function seamlessly into its automated workflow.

Material science plays a crucial role in machine performance differentiation. CNC models typically incorporate hardened tool steel components with advanced surface treatments like titanium nitride coating, achieving 5-8 times longer service life compared to standard carbon steel parts in conventional machines. The automated systems also employ servo-electric drives that reduce energy consumption by 25-40% compared to hydraulic systems commonly found in manual units. However, this technological sophistication comes with greater initial investment and maintenance complexity—factors that lead many small-scale manufacturers to opt for traditional models.

Application environments further highlight the distinction between these technologies. Automotive filter production, demanding both high throughput and consistent quality, overwhelmingly favors CNC systems. Their ability to store hundreds of pleating recipes allows instant switching between different filter types—from diesel particulate filters requiring ultra-precise 2mm pleats to oil filters needing wider 5mm spacing. Conversely, the textile industry frequently utilizes manual pleaters for decorative fabric processing, where absolute precision is less critical than material handling flexibility.

Emerging Industry 4.0 capabilities are reshaping the value proposition of CNC pleating equipment. Modern systems now incorporate predictive maintenance algorithms that analyze vibration patterns and force feedback to anticipate blade wear before it affects product quality. Some advanced models even feature machine vision systems that automatically detect material defects during the feeding process. These developments are gradually creating a performance gap that manual machines cannot bridge, particularly in regulated industries like medical filtration where documentation of every production parameter is mandatory.

The choice between these technologies ultimately depends on production scale, material diversity, and quality requirements. While CNC systems dominate high-volume precision applications, conventional pleaters continue serving niche markets where their mechanical simplicity and lower capital cost provide compelling advantages. As smart manufacturing advances, the next generation of hybrid machines may combine the flexibility of manual operation with the precision of computerized control, potentially redefining industry standards once again.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.