Diamond Drill Bits: Ultimate Guide to Precision Drilling

Diamond drilling technology has revolutionized how professionals approach challenging materials in various industries. From aerospace manufacturing to semiconductor production, drill bits diamond solutions provide unmatched precision and durability for the most demanding applications.

The superiority of diamond-embedded drilling tools lies in their exceptional hardness and thermal conductivity. These characteristics make them indispensable for working with materials that would quickly wear down conventional drilling equipment. Whether you're drilling through ceramics, composites, or advanced technical materials, diamond drill bits deliver consistent performance and extended tool life.

Understanding Diamond Drill Bit Technology

Diamond drill bits incorporate industrial diamonds into their cutting surfaces through various manufacturing processes. These synthetic diamonds, typically produced under controlled high-pressure and high-temperature conditions, offer consistent quality and performance characteristics that natural diamonds cannot match in industrial applications.

The bonding matrix that holds these diamonds determines the drill bit's performance characteristics. Resin bonds provide sharp cutting action for softer materials, while metal bonds offer durability for harder substrates. Understanding these distinctions helps professionals select the appropriate tool for their specific applications.

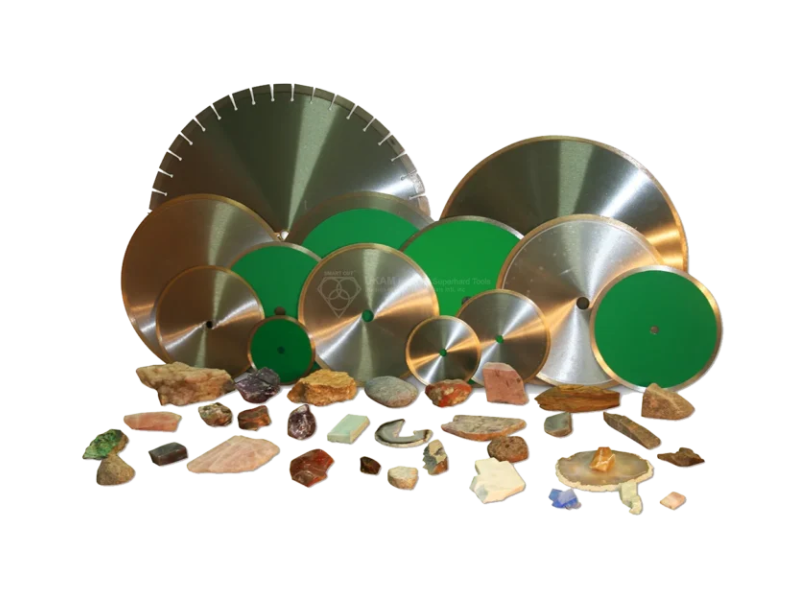

Types of Diamond Drill Bits

Several categories of diamond drill bits serve different industrial needs. Electroplated diamond bits feature diamonds bonded to the surface using electrochemical processes, providing excellent initial cutting performance. These tools work exceptionally well for glass, ceramics, and stone materials.

Sintered diamond bits incorporate diamonds throughout the cutting matrix, offering longer tool life and consistent performance as the bit wears. This construction makes them ideal for production environments where tool changes must be minimized.

Brazed diamond bits use high-temperature brazing to attach diamond segments to the bit body. This method creates powerful bonds suitable for heavy-duty applications and extended use cycles.

Applications Across Industries

The photonics industry relies heavily on precision drilling for manufacturing fiber optic components, laser components, and optical devices. These applications demand exceptional accuracy and surface finish quality that only diamond drilling technology can provide.

Aerospace manufacturers use diamond drill bits for creating precise holes in composite materials, titanium alloys, and ceramic matrix composites. The ability to maintain tight tolerances while processing these challenging materials makes diamond bits essential for critical aircraft components.

Medical device manufacturing represents another crucial application area. Diamond drill bits enable the production of miniaturized components with extremely tight tolerances, essential for modern medical instruments and implantable devices.

Semiconductor Manufacturing Applications

The semiconductor industry demands unprecedented precision in drilling operations. Diamond drill bits facilitate the creation of micro-vias in circuit boards, precise holes in silicon wafers, and channels in ceramic substrates used in electronic packaging.

Processing speeds in semiconductor manufacturing require tools that maintain accuracy while operating at high velocities. Diamond drill bits meet these demands through their superior wear resistance and thermal management properties.

Benefits of Diamond Core Drills

Diamond core drills offer unique advantages for hollow drilling applications. These specialized tools remove cylindrical cores from materials while maintaining the integrity of both the core and the surrounding material.

The hollow design of core drills reduces drilling forces and heat generation compared to solid drill bits. This characteristic proves particularly valuable when working with brittle materials that might crack under excessive stress or thermal shock.

Core drilling also enables material analysis and quality control processes. The extracted cores provide samples for testing and verification without compromising the integrity of the main workpiece.

Heat Management in Diamond Drilling

Effective heat management distinguishes professional diamond drilling operations from amateur attempts. Diamond drill bits generate heat through friction, and excessive temperatures can damage both the tool and the workpiece.

Proper coolant selection and application methods significantly impact drilling performance and tool life. Water-based coolants work well for most applications, while specialized synthetic coolants may be necessary for certain materials or extreme operating conditions.

Cutting parameters such as speed, feed rate, and depth of cut must be optimized for each material and application. Too aggressive parameters generate excessive heat and premature tool wear, while overly conservative settings reduce productivity and may cause tool loading.

Selection Criteria for Diamond Drill Bits

Material hardness represents the primary factor in diamond drill bit selection. Harder materials generally require bits with higher diamond concentrations and more robust bonding systems. Softer materials may benefit from bits with larger diamond particles and more aggressive cutting geometries.

Hole size and depth requirements influence bit selection significantly. Smaller diameter bits require different diamond distributions and bonding systems compared to larger diameter tools. Deep hole drilling applications may necessitate specialized chip evacuation features and enhanced coolant delivery systems.

Surface finish requirements also impact bit selection. Applications demanding mirror-like finishes require different diamond specifications than those where rougher finishes are acceptable.

Quality Considerations

Consistent diamond distribution throughout the cutting surface ensures uniform wear patterns and predictable tool life. Inferior bits may exhibit uneven diamond placement, leading to premature failure and poor hole quality.

The strength of the bond between diamonds and the matrix material determines how long the cutting edges remain effective. High-quality bits maintain their cutting ability throughout their service life, while inferior products may lose diamonds prematurely.

Manufacturing precision in the bit body affects concentricity, balance, and overall drilling accuracy. Professional-grade bits undergo rigorous quality control processes to ensure dimensional accuracy and performance consistency.

Operational Best Practices

Proper machine setup ensures optimal drilling performance and tool life. Spindle runout should be minimized, and workpiece clamping must provide adequate support without inducing stress concentrations that could cause cracking.

Starting holes at the correct angle prevents bit wandering and ensures accurate hole placement. Gradual engagement reduces shock loads that could damage either the bit or the workpiece.

Maintaining consistent feed rates throughout the drilling operation prevents tool overheating and ensures uniform hole quality. Variable feed rates can cause tool wear patterns that compromise performance.

Troubleshooting Common Issues

Chipping around hole edges typically indicates excessive cutting speeds or inadequate workpiece support. Reducing cutting parameters and improving workpiece fixturing usually resolves these issues.

Rapid tool wear may result from incorrect cutting parameters, inadequate cooling, or using the wrong bit type for the application. Systematic evaluation of these factors helps identify the root cause.

Poor hole quality, including taper or surface roughness, often stems from machine-related issues such as excessive runout or vibration. Addressing these mechanical problems typically improves drilling results significantly.

Maintenance and Tool Life Extension

Regular inspection of diamond drill bits helps identify wear patterns and potential problems before they affect hole quality. Visual examination under magnification reveals diamond condition and matrix wear patterns.

Proper cleaning removes built-up debris that can interfere with cutting action and heat dissipation. Ultrasonic cleaning proves effective for removing stubborn deposits without damaging the diamond cutting surface.

Storage in protective containers prevents damage to the delicate cutting edges. Diamond bits should be stored separately to prevent contact that could chip or dull the cutting surfaces.

Reconditioning Options

Some diamond drill bits can be reconditioned through specialized processes that restore cutting performance. Diamond re-coating or matrix renewal extends tool life and provides cost savings for high-value bits.

The economics of reconditioning depend on the original bit cost and the complexity of the reconditioning process. High-performance bits used in critical applications often justify reconditioning costs.

Future Developments in Diamond Drilling Technology

Advances in synthetic diamond production continue to improve the consistency and performance of diamond drill bits. New diamond synthesis methods produce crystals with enhanced properties for specific applications.

Nanotechnology applications in bonding systems promise improved diamond retention and cutting performance. These developments may enable thinner cutting edges and reduced cutting forces.

Smart tooling concepts incorporating sensors for real-time monitoring of cutting conditions represent the next frontier in diamond drilling technology. These systems could automatically adjust parameters for optimal performance and tool life.

Frequently Asked Questions

What makes diamond drill bits superior to carbide alternatives?

Diamond drill bits offer significantly higher hardness and thermal conductivity compared to carbide tools. This combination enables drilling through materials that would quickly destroy carbide bits while maintaining superior accuracy and surface finish quality.

How do I determine the correct cutting speed for diamond drill bits?

Cutting speed depends on the material being drilled, bit diameter, and application requirements. Generally, harder materials require slower speeds, while softer materials can accommodate higher speeds. Manufacturer recommendations provide excellent starting points for optimization.

Can diamond drill bits be used without coolant?

While some diamond bits can operate dry for short periods, coolant use dramatically improves performance and tool life. Coolant removes heat, flushes away debris, and reduces wear on both the bit and workpiece.

What causes premature diamond bit failure?

Common causes include excessive cutting speeds, inadequate cooling, improper workpiece support, and using the wrong bit type for the application. Mechanical issues such as spindle runout or excessive vibration also contribute to premature failure.

How should diamond drill bits be stored?

Diamond bits should be stored in protective containers that prevent contact between cutting surfaces. Individual protective sleeves or dedicated storage blocks work well. Avoid storing different bit types together to prevent damage.

Is it worth reconditioning expensive diamond drill bits?

Reconditioning can be cost-effective for high-value bits used in critical applications. The decision depends on the original bit cost, available reconditioning services, and the specific application requirements.

Diamond drilling technology continues evolving to meet increasingly demanding industrial requirements. Understanding the principles behind these advanced tools enables professionals to maximize their investment while achieving superior results in their most challenging drilling applications.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.