Metallographic Diamond Blade: Complete Guide & Applications

Precision cutting in metallography demands exceptional tools, and the metallographic diamond blade stands as the gold standard for materials analysis and research applications. These specialized cutting instruments deliver unmatched accuracy when sectioning metal samples, ceramics, composites, and other hard materials for microscopic examination. Understanding the selection, application, and maintenance of metallographic diamond blades is crucial for achieving consistent, high-quality results in laboratory and industrial settings.

Understanding Metallographic Diamond Blades

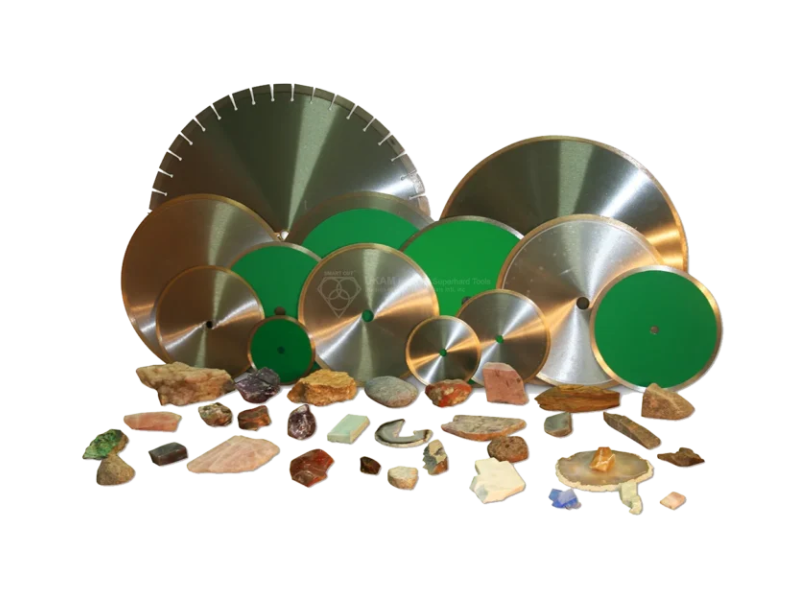

Metallographic diamond blades represent a sophisticated fusion of engineering precision and cutting-edge materials science. Unlike conventional abrasive wheels, these blades incorporate industrial-grade diamond particles bonded within specialized matrices designed for specific cutting applications.

The construction of metallographic diamond blades involves embedding diamond crystals in metal bonds, resin bonds, or electroplated coatings. Each bonding system offers distinct advantages depending on the material being cut and the desired surface finish. Metal-bonded blades excel in cutting hard, abrasive materials like carbides and ceramics, while resin-bonded variants provide superior finishes on softer metals and composites.

Key Features of Professional Diamond Blades

Professional metallographic diamond blades incorporate several critical design elements that distinguish them from standard cutting tools. The diamond concentration, typically measured in carats per cubic centimeter, directly influences cutting performance and blade longevity. Higher concentrations provide increased cutting power but may reduce blade life due to premature diamond pullout.

Blade thickness plays a crucial role in cutting precision and kerf width. Thinner blades minimize material waste and reduce heat generation during cutting, while thicker variants offer greater stability for larger specimens. The rim design, whether continuous or segmented, affects cooling efficiency and chip evacuation during the cutting process.

Applications in Materials Analysis

Laboratory Sample Preparation

Metallographic diamond blades serve as essential tools in laboratory sample preparation workflows. Research facilities, quality control laboratories, and academic institutions rely on these precision instruments to prepare specimens for microstructural analysis, hardness testing, and compositional studies.

The ability to achieve consistent, deformation-free cuts makes these blades invaluable for preparing samples that require an accurate representation of the original material structure. Whether sectioning heat-treated steels, exotic alloys, or advanced composites, metallographic diamond blades preserve the integrity of microstructural features essential for accurate analysis.

Industrial Quality Control

Manufacturing industries utilize metallographic diamond blades for routine quality control procedures and failure analysis investigations. Automotive manufacturers employ these tools to examine engine components, while aerospace companies rely on them for critical safety inspections of turbine blades and structural elements.

The precision cutting capabilities enable engineers to expose internal defects, evaluate weld quality, and assess material uniformity across production batches. This application proves particularly valuable in industries where material performance directly impacts safety and reliability.

Selecting the Right Diamond Blade

Material Considerations

Proper blade selection begins with understanding the specific material properties of the specimens being cut. Hardness, abrasiveness, and thermal sensitivity all influence the optimal blade choice. Ferrous metals typically require different blade specifications compared to non-ferrous alloys, ceramics, or composite materials.

The Mohs hardness scale provides a useful reference point for initial blade selection. Materials above 7 on the Mohs scale generally require metal-bonded diamond blades, while softer materials may be effectively cut with resin-bonded alternatives. However, other factors such as thermal conductivity and chemical reactivity must also be considered.

Bond Type Selection

The bond matrix holding the diamond particles significantly impacts cutting performance and blade life. Metal bonds, typically composed of bronze, cobalt, or iron alloys, provide excellent diamond retention and extended blade life when cutting hard, abrasive materials. These bonds wear slowly, exposing fresh diamond particles as cutting progresses.

Resin bonds offer superior cutting speeds and finish quality but may wear more rapidly than metal alternatives. Electroplated bonds provide the fastest cutting action but generally offer shorter blade life. Understanding these trade-offs enables users to select the most cost-effective blade for their specific applications.

Optimal Cutting Techniques

Speed and Feed Parameters

Achieving optimal cutting results requires careful attention to operating parameters. Cutting speed, measured in surface feet per minute, must be balanced against feed rate to prevent overheating and premature blade wear. Generally, harder materials require slower cutting speeds to prevent diamond degradation.

Feed rates should be adjusted to maintain consistent cutting loads without overwhelming the blade's capacity. Excessive feed rates can cause blade deflection, poor surface finish, and premature failure. Conversely, insufficient feed may result in glazing, where the bond matrix becomes polished and fails to expose fresh diamond particles.

Cooling and Lubrication Systems

Effective cooling during metallographic cutting operations is essential for maintaining blade performance and specimen integrity. Heat generation can alter material microstructures, particularly in heat-sensitive alloys and precipitation-hardened materials. Water soluble coolant systems provide efficient heat removal while offering environmental advantages over oil-based alternatives.

Modern cutting coolant formulations incorporate corrosion inhibitors, biocides, and surface-active agents that enhance cutting performance while protecting both the specimen and cutting equipment. Proper coolant concentration and flow rates are critical for achieving optimal results.

Maintenance and Blade Life Extension

Proper Storage and Handling

Metallographic diamond blades require careful storage and handling to maintain their precision cutting capabilities. Blades should be stored in protective containers to prevent damage to the cutting edge and diamond segments. Temperature fluctuations and humidity can affect certain bond types, particularly resin-bonded variants.

Regular inspection of blade condition helps identify wear patterns and potential problems before they impact cutting quality. Visual examination should focus on diamond exposure, bond wear patterns, and any signs of damage or contamination.

Dressing and Conditioning

Periodic blade dressing helps maintain optimal cutting performance by exposing fresh diamond particles and removing glazed bond material. Dressing stones or sticks designed for diamond blade conditioning should be used according to manufacturer recommendations.

The dressing process involves light contact between the dressing tool and the rotating blade under controlled conditions. Proper dressing technique extends blade life, improves cutting quality, and maintains consistent performance throughout the blade's service life.

Troubleshooting Common Issues

Poor Surface Finish

Surface finish problems often result from improper cutting parameters, worn blades, or inadequate cooling. Increasing cutting speed while reducing feed rate typically improves surface quality. However, this adjustment must be balanced against increased heat generation and potential thermal damage.

Blade condition plays a significant role in surface finish quality. Worn or glazed blades produce rough, torn surfaces that may require additional preparation steps. Regular blade inspection and timely replacement prevent these quality issues.

Premature Blade Wear

Excessive blade wear typically indicates parameter optimization opportunities or material-specific challenges. Operating speeds that are too high for the material being cut can cause rapid diamond degradation and shortened blade life. Similarly, inadequate cooling or improper coolant selection may accelerate wear rates.

Material contamination or unexpected hardness variations can also contribute to premature blade failure. Proper specimen preparation and material characterization help identify potential issues before cutting begins.

Safety Considerations

Personal Protective Equipment

Safe operation of metallographic cutting equipment requires appropriate personal protective equipment and adherence to established safety protocols. Eye protection, hearing protection, and respiratory protection may be necessary depending on the materials being cut and the work environment.

Proper ventilation systems help remove airborne particles and coolant mist that may be generated during cutting operations. Emergency stop procedures and equipment lockout protocols ensure operator safety during maintenance and blade changes.

Equipment Maintenance

Regular equipment maintenance ensures safe operation and optimal cutting performance. Spindle bearings, coolant systems, and safety interlocks require periodic inspection and service according to manufacturer recommendations.

Blade mounting procedures must be followed precisely to prevent dangerous blade failure or ejection. Proper torque specifications and mounting hardware conditions are critical safety factors that should never be compromised.

Frequently Asked Questions

What makes metallographic diamond blades different from regular cutting discs?

Metallographic diamond blades use industrial diamond particles in specialized bond matrices for precision cutting of hard materials with minimal deformation.

How do I choose between metal-bonded and resin-bonded diamond blades?

Metal-bonded blades work best for hard, abrasive materials, while resin-bonded blades provide better finishes on softer metals and faster cutting speeds.

What cutting speed should I use for steel samples?

Steel cutting speeds typically range from 200-400 surface feet per minute, depending on the specific alloy and blade specifications.

How often should I dress my diamond blade?

Blade dressing frequency depends on usage, but generally, every 10-20 cuts or when cutting quality begins to deteriorate.

Can I cut different materials with the same blade?

While possible, dedicated blades for specific material types provide optimal performance and longer blade life.

What causes diamond blades to glaze over?

Glazing occurs when cutting parameters are too conservative, preventing proper bond wear and diamond exposure.

How do I know when to replace a diamond blade?

Replace blades when cutting quality deteriorates, cutting times increase significantly, or visible wear indicators show excessive wear.

Is coolant always necessary when using diamond blades?

While not always mandatory, coolant significantly improves cutting quality, blade life, and prevents thermal damage to specimens.

Conclusion

Metallographic diamond blades represent essential tools for precision cutting applications in materials analysis and quality control. Understanding blade selection criteria, optimal cutting parameters, and proper maintenance procedures enable users to achieve consistent, high-quality results while maximizing blade life and cost-effectiveness. Investment in quality diamond blades and proper cutting techniques pays dividends through improved sample quality, reduced preparation time, and enhanced analytical accuracy.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.