Rock Saw Blades: Professional Cutting Applications

In the world of industrial cutting and precision materials processing, diamond rock cutting blades stand as the unrivaled champions of efficiency and accuracy. Whether you're a seasoned professional in construction, a laboratory technician working with geological samples, or a hobbyist rockhound, understanding the ins and outs of high-quality rock saw blades can significantly impact your work's outcome and efficiency.

The Evolution of Modern Cutting Technology

The journey of rock saw blade technology has been one of constant innovation. From primitive manual tools to today's advanced diamond-embedded precision instruments, the evolution has been driven by the need for greater accuracy, speed, and versatility in cutting increasingly challenging materials.

Today's premium rock saw blades, like those manufactured by UKAM Industrial Superhard Tools, represent the pinnacle of this evolution. Combining cutting-edge materials science with precision engineering, these tools transform what was once laborious work into streamlined processes with predictable, high-quality results.

Understanding Diamond Rock Saw Blade Construction

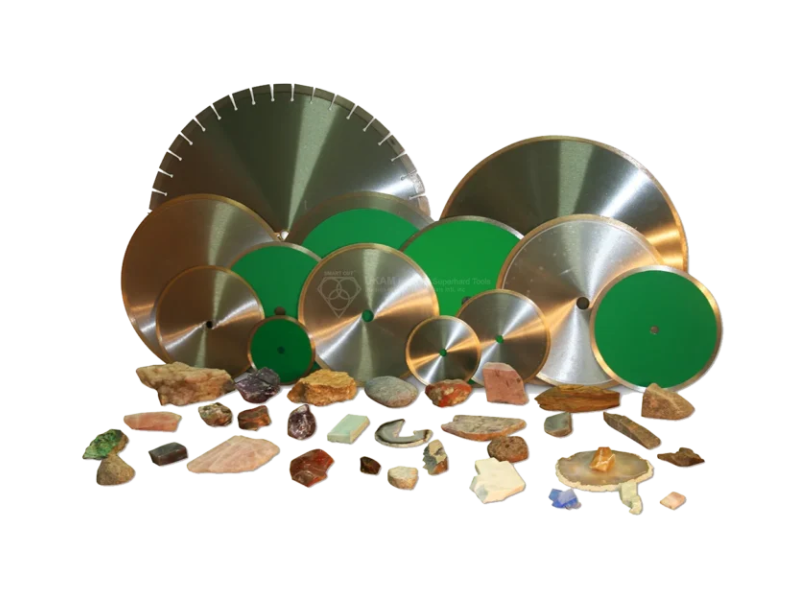

At the heart of every superior rock saw blade lies its construction methodology. The most effective blades feature:

- Diamond Concentration: The quantity and quality of diamonds embedded in the blade significantly affect cutting performance

- Bond Matrix: This metal alloy holds the diamonds in place and determines wear resistance

- Core Material: Usually high-grade steel that provides stability and reduces wobble

- Segment Design: The pattern and arrangement of cutting segments impact cooling efficiency and debris removal

For specialized applications, such as those requiring a Struers Saw compatible blade, the construction parameters are even more critical. These precision instruments demand blades manufactured to exacting tolerances to maintain sample integrity during sectioning.

Selecting the Right Blade for Your Application

Choosing the appropriate rock saw blade involves understanding several key factors:

Material Hardness

Different materials require specific blade designs:

- Soft to medium materials like limestone benefit from blades with lower diamond concentration

- Extremely hard materials like granite or engineered quartz need higher diamond content and specialized bond matrices

- Abrasive materials demand blades with controlled wear rates to maintain cutting efficiency

Cutting Environment

The cutting environment dramatically impacts blade selection:

- Wet cutting allows for higher speeds and extends blade life

- Dry cutting requires specialized heat-resistant designs

- Laboratory environments may necessitate contamination-free blade compositions

When working with precision equipment like a Struers Saw, environmental considerations become even more crucial as these machines often operate in controlled laboratory settings where precision and cleanliness are paramount.

Maximizing Performance and Longevity

Even the finest rock saw blades require proper usage techniques to perform optimally:

Proper Speed Selection

Operating at the correct RPM is critical:

- Too slow: Premature blade wear and inefficient cutting

- Too fast: Overheating and possible blade damage

- Optimal: Each blade has a recommended speed range based on its design and the target material

Cutting Depth Considerations

For efficient cutting:

- Use incremental depth increases for harder materials

- Maintain consistent feed rates appropriate to the material

- Allow the blade to do the work without excessive pressure

Cooling Techniques

Effective cooling extends blade life and improves cut quality:

- Ensure adequate water flow for wet-cutting applications

- Monitor blade temperature during dry cutting

- Consider specialized coolants for laboratory applications

Advanced Applications in Scientific Research

In scientific and research environments, rock saw blades serve critical functions beyond construction applications. When using specialized equipment like a [Struers Saw](https://ukam.com/struers-cutting.html), researchers demand uncompromising precision for:

- Geological sample preparation

- Mineralogical analysis

- Materials science research

- Archaeological artifact preservation

These applications require blades that not only cut effectively but also preserve the integrity of often irreplaceable samples. The blade must create minimal heat, avoid contamination, and produce surfaces suitable for immediate analysis without extensive additional preparation.

Technological Innovations Shaping the Future

The rock saw blade industry continues to evolve with several exciting developments:

Nano-diamond Technology

Ultra-fine diamond particles create blades with:

- Smoother cutting surfaces

- Reduced kerf loss

- Extended working life

- Superior performance on exotic materials

Custom Formulations

Modern manufacturing allows for application-specific blade designs:

- Material-specific bond hardness

- Optimized segment geometry

- Specialized cooling channels

- Application-tuned diamond exposure rates

Sustainability Improvements

Newer manufacturing techniques focus on:

- Reduced environmental impact

- Reclaimed diamond utilization

- Energy-efficient production methods

- Extended blade lifecycles

Choosing a Quality Supplier

When investing in rock saw blades, partnering with an established manufacturer like UKAM Industrial Superhard Tools provides several advantages:

- Access to application-specific technical expertise

- Consistent quality control standards

- Comprehensive product support

- Custom solutions for specialized applications

For specialized laboratory equipment like the Struers Saw, working with suppliers who understand the unique requirements of these precision machines ensures optimal performance and sample integrity.

Conclusion

The humble rock saw blade represents a fascinating intersection of materials science, precision engineering, and practical application. Whether you're cutting stone for a construction project, preparing samples in a research laboratory, or pursuing a passionate hobby, selecting the appropriate blade dramatically impacts your results.

By understanding the core principles behind rock saw blade design and application, you'll be equipped to make informed decisions that improve efficiency, reduce costs, and elevate the quality of your work. As technology continues to advance, we can expect even more impressive innovations that will further transform what's possible in the world of precision cutting.

For those seeking the pinnacle of cutting technology, exploring the offerings from industry leaders like UKAM Industrial Superhard Tools provides access to cutting-edge solutions backed by decades of specialized experience and ongoing innovation.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.