Professional Diamond Lapidary Blades Guide

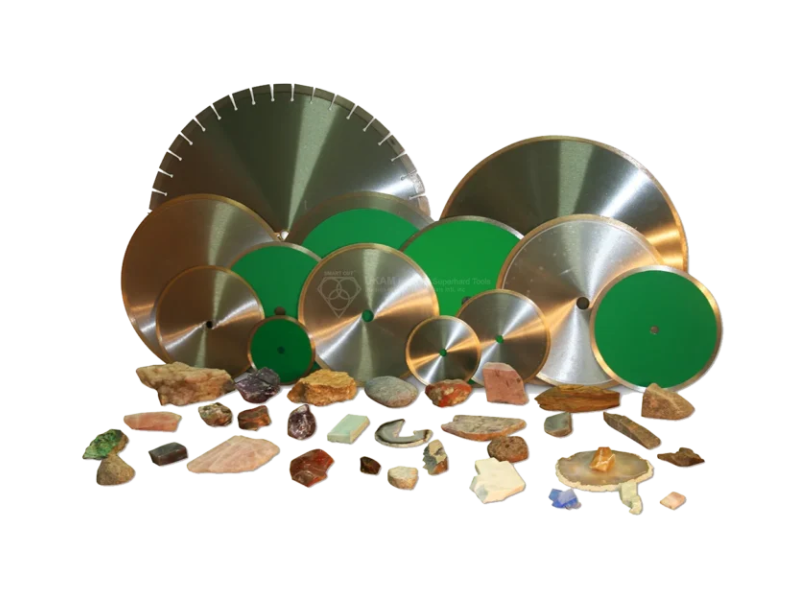

Professional gemstone cutting and shaping requires precision tools that deliver consistent results. Diamond lapidary blades represent the pinnacle of cutting technology for lapidary enthusiasts and professionals working with precious stones, minerals, and hard materials. These specialized cutting tools combine industrial-grade diamonds with engineered substrates to create smooth, precise cuts in even the hardest materials.

Understanding Diamond Lapidary Blade Construction

Diamond lapidary blades feature a unique construction that sets them apart from conventional cutting tools. The blade core typically consists of steel or specialized alloys designed to maintain stability during high-speed rotation. The cutting edge incorporates industrial diamonds bonded to the rim using various techniques, including electroplating, sintering, or brazing.

The diamond particles vary in size and concentration depending on the intended application. Finer grits produce smoother finishes but cut more slowly, while coarser grits remove material quickly but may leave rougher surfaces. Understanding this relationship helps lapidary workers select the appropriate blade for their specific projects.

Types of Diamond Bonding Systems

Different bonding systems affect blade performance and longevity. Electroplated blades offer excellent cutting speed and are ideal for softer stones, while sintered blades provide superior durability for extended use. Brazed diamond blades combine the benefits of both systems, offering excellent cutting performance with extended tool life.

Selecting the Right Blade for Your Project

Choosing the correct diamond lapidary blade depends on several factors, including material hardness, desired finish quality, and cutting speed requirements. Softer materials like turquoise or amber require different blade specifications compared to harder stones like sapphire or jade.

Blade diameter affects both cutting depth and surface speed. Larger blades cut deeper but require more powerful equipment, while smaller blades offer greater control for detailed work. The blade thickness also influences the kerf width and material waste during cutting operations.

Specialized Applications and Related Technologies

Beyond standard lapidary work, diamond cutting technology extends to precision applications requiring extreme accuracy. Diamond dicing blades serve the semiconductor and electronics industries, where microscopic precision is essential. These ultra-thin blades create precise separations in silicon wafers and electronic components.

Similarly, wafering blades enable the production of thin material sections for research and analysis. These specialized tools maintain parallel surfaces while minimizing material loss during sectioning operations.

Cooling and Lubrication Systems

Proper cooling prevents blade overheating and extends tool life significantly. Water cooling systems remove heat generated during cutting while flushing away debris that could interfere with the cutting process. Some applications benefit from oil-based coolants that provide superior lubrication for specific materials.

Maintenance and Care Best Practices

Regular maintenance ensures optimal blade performance and maximizes tool investment. Cleaning diamond blades after each use removes accumulated debris that can reduce cutting efficiency. Proper storage in dry conditions prevents corrosion of the blade substrate.

Dressing diamond blades periodically restores cutting performance by exposing fresh diamond particles. This process involves cutting through abrasive materials that wear away the bonding material and reveal new cutting edges.

Safety Considerations

Working with diamond lapidary blades requires proper safety equipment and procedures. Eye protection shields against flying particles, while dust collection systems prevent inhalation of potentially harmful particulates. Secure workpiece clamping prevents dangerous movement during cutting operations.

Advanced Cutting Techniques

Experienced lapidary workers employ various techniques to achieve superior results. Feed rate control balances cutting speed with surface quality, while proper blade angle optimization reduces chipping and improves edge quality. Understanding material grain structure helps predict cutting behavior and prevent fractures.

Temperature monitoring during extended cutting operations prevents thermal damage to both the workpiece and cutting tool. Gradual feeding techniques allow heat dissipation while maintaining steady material removal rates.

Economic Considerations and Tool Life

High-quality diamond lapidary blades represent significant investments that require careful consideration of cost per cut rather than initial purchase price. Premium blades often provide superior value through extended tool life and consistent performance.

Tracking blade performance metrics helps optimize replacement schedules and identify the most cost-effective tools for specific applications. Regular performance evaluation ensures maximum return on tool investments.

Frequently Asked Questions

What grit size should I choose for my diamond lapidary blade?

Select 100-200 grit for rough cutting, 400-600 for general shaping, and 1000+ grit for finishing work.

How often should I dress my diamond blade?

Dress blades when cutting performance noticeably decreases, typically after 2-4 hours of continuous use.

Can I use the same blade for different materials?

While possible, dedicated blades for specific materials provide optimal results and longer tool life.

What cooling method works best for diamond lapidary blades?

Water cooling effectively removes heat while flushing debris, making it ideal for most lapidary applications.

How do I know when to replace my diamond blade?

Replace blades when the diamond layer is completely worn away or when the substrate shows significant wear or damage.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.