Enhance Collaboration and Efficiency with Skilled Sheet Metal Design Drawings Services

In the competitive world of manufacturing and fabrication, achieving high-quality results efficiently depends heavily on clear communication, precise design, and streamlined processes. For businesses involved in sheet metal fabrication, utilizing skilled sheet metal design drawings services can dramatically improve collaboration among teams, reduce errors, and accelerate project timelines. This article explores how these services—ranging from sheet metal detailing to advanced engineering drawings—can transform your manufacturing workflows.

The Significance of Accurate Sheet Metal Detailing Services

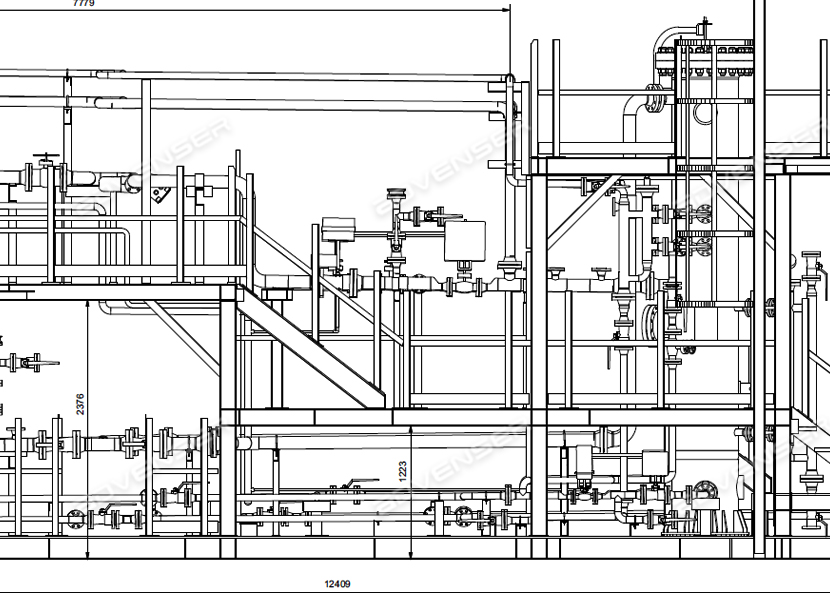

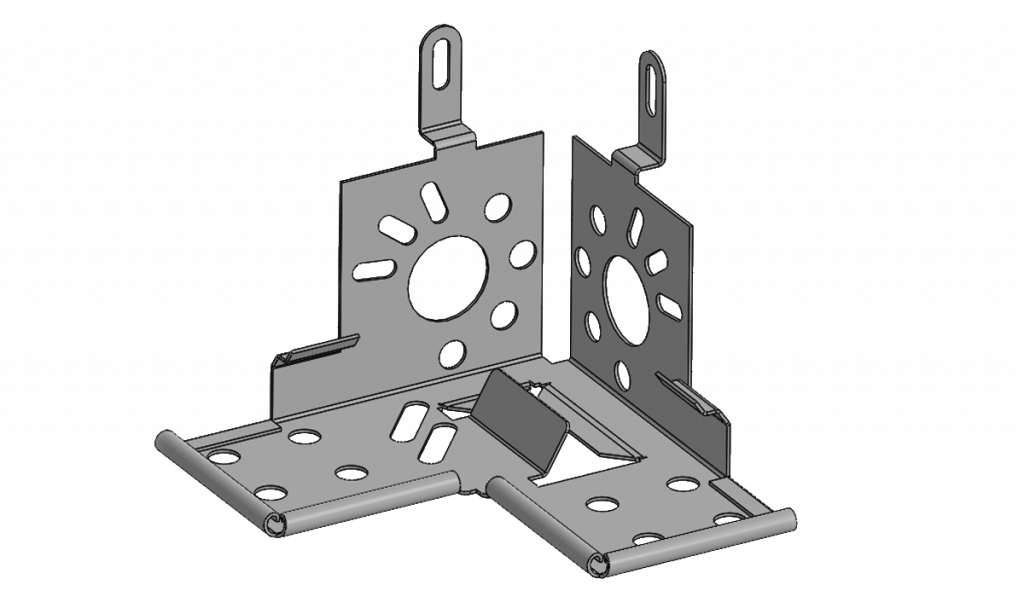

At the foundation of successful sheet metal fabrication lies detailed sheet metal detailing services. These services involve creating comprehensive drawings that specify every aspect of the part, including dimensions, bend allowances, hole placements, flange details, and material specifications. Accurate detailing ensures that each component is manufactured precisely as intended, reducing material wastage and rework.

Proper sheet metal detailing also accounts for manufacturing considerations such as bend radii and springback, which are critical for achieving the desired fit and finish. Outsourcing sheet metal detailing services to experienced professionals provides access to industry-standard practices and software, leading to better quality and consistency.

The Benefits of Sheet Metal Design Outsourcing Services

Outsourcing sheet metal design services has become a strategic choice for many companies aiming to improve efficiency. By partnering with specialized service providers, organizations can:

- Access Expertise: Benefit from skilled engineers familiar with various design standards and manufacturing processes.

- Save Time and Cost: Reduce the need for in-house resources and minimize project turnaround times.

- Focus on Core Activities: Allocate internal resources to areas like marketing, sales, or product development.

- Scale Operations: Quickly adapt to increased demand without the need for additional hiring or infrastructure

These advantages make sheet metal design outsourcing services a valuable asset for small and large enterprises alike.

The Role of Sheet Metal Drafting Services in Modern Manufacturing

Sheet metal drafting services involve creating detailed 2D and 3D drawings that serve as the blueprint for manufacturing. These services use advanced CAD software to generate precise representations of parts and assemblies. The benefits include:

- Clear Communication: Well-drafted drawings eliminate ambiguity, ensuring everyone involved understands the specifications.

- Design Verification: Engineers can perform simulations and stress analysis directly on CAD files before fabrication.

- Easy Modifications: Digital drawings allow quick adjustments, reducing lead times.

- Standardization: Ensures designs comply with industry standards like ISO, ASME, or customer-specific requirements.

- Effective sheet metal drafting is essential for aligning design intent with manufacturing capabilities.

Using SolidWorks Sheet Metal Drawing Services

SolidWorks has emerged as a leading software platform for sheet metal design. Its specialized tools enable engineers to create accurate, parametric models that account for material properties and manufacturing constraints. Key advantages include:

- Automated Bends and Flanges: Simplify complex geometries with features that automatically generate bend lines and flange details.

- Flattened Pattern Generation: Easily produce flat patterns for laser cutting, ensuring precise material layout.

- Design Validation: Run simulations for stress, deformation, and springback analysis.

- Collaboration: Share design files seamlessly across teams, suppliers, and clients.

Using SolidWorks sheet metal drawing services enhances accuracy, reduces errors, and speeds up the overall design-to-fabrication process.

Enhancing Collaboration with Sheet Metal Engineering Drawing Services

Effective collaboration depends on comprehensive and clear engineering drawings. These services translate conceptual ideas into detailed, industry-standard drawings that all stakeholders can interpret. High-quality sheet metal engineering drawing services facilitate:

- Cross-Functional Communication: Ensuring engineers, fabricators, and quality assurance teams are aligned.

- Supplier Coordination: Providing suppliers with precise specifications to minimize discrepancies.

- Customer Engagement: Allowing clients to review and approve designs confidently.

- Documentation and Traceability: Keeping detailed records for future reference, quality audits, or modifications.

By investing in expert engineering drawing services, companies can reduce misunderstandings and ensure smoother project execution.

Design Optimization for Manufacturing Efficiency

Skilled sheet metal design services do more than just create drawings—they optimize designs for manufacturing. This includes:

- Material Optimization: Selecting the best materials that balance cost, strength, and weight.

- Part Minimization: Reducing the number of parts through design integration.

- Ease of Assembly: Designing parts that are easier to assemble, reducing labor costs.

- Tolerance Analysis: Ensuring parts fit together correctly despite manufacturing variances.

- Cost Reduction: Identifying opportunities to minimize material use and fabrication steps.

Design optimization leads to faster production, lower costs, and higher-quality products.

Integrating CNC Machining and Fabrication Technologies

Modern sheet metal fabrication often involves CNC machining, laser cutting, punch press operations, and welding. Skilled sheet metal drawings services ensure compatibility with these technologies by:

Providing detailed instructions for CNC programming.

Including flat patterns for laser cutting.

Specifying bend sequences for press brakes.

Indicating weld points and assembly instructions.

This integration streamlines manufacturing workflows, reduces setup times, and minimizes errors.

Sustainability and Material Considerations

Today’s manufacturing also emphasizes sustainability. Expert sheet metal design services incorporate eco-friendly practices by:

- Designing for Material Efficiency: Reducing scrap and waste.

- Choosing Sustainable Materials: Using recyclable or low-impact materials.

- Facilitating Reuse and Recycling: Creating parts that can be easily disassembled and recycled.

Incorporating sustainability into design not only benefits the environment but can also lead to cost savings and enhanced brand reputation.

Conclusion

Investing in professional sheet metal design drawings services is essential for modern manufacturing success. Whether you’re outsourcing sheet metal design services, utilizing advanced software like SolidWorks, or focusing on detailed engineering drawings, these efforts promote better collaboration, reduce errors, and accelerate project timelines. As technology advances, embracing comprehensive sheet metal fabrication design services will continue to be a key differentiator in delivering innovative, cost-effective, and sustainable products.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.